DESCRIPTION Refer to DTCs C1415 and C1416. Click here

|

DTC No. | Detection Item |

INF Code | DTC Detection Condition |

Trouble Area | MIL |

Note | | C1407 |

Open or Short in Rear Speed Sensor RH Circuit |

523 526 528 |

- INF Code: 523

- An open in the speed sensor signal circuit continues for 0.5 seconds or more.

- INF Code: 526

- The speed sensor power source voltage is low for 0.5 seconds or more.

- INF Code: 528

- The speed sensor power source voltage is low for 0.2 seconds, and does not return to normal for 60 seconds or more.

|

- Skid control sensor wire RH (No. 1 parking brake wire assembly)

- Rear speed sensor RH (rear axle hub and bearing assembly RH)

- Wire harness or connector

- Skid control ECU (brake booster with master cylinder assembly)

| Comes on |

- INF Code 523: SAE Code C0514 and C0515

- INF Code 526: SAE Code C14EA (Case 1)

- INF Code 528: SAE Code C14EA (Case 2)

- ABS DTC

| | C1408 |

Open or Short in Rear Speed Sensor LH Circuit |

533 536 538 |

- INF Code: 533

- An open in the speed sensor signal circuit continues for 0.5 seconds or more.

- INF Code: 536

- The speed sensor power source voltage is low for 0.5 seconds or more.

- INF Code: 538

- The speed sensor power source voltage is low for 0.2 seconds, and does not return to normal for 60 seconds or more.

|

- Skid control sensor wire LH (No. 2 parking brake wire assembly)

- Rear speed sensor LH (rear axle hub and bearing assembly LH)

- Wire harness or connector

- Skid control ECU (brake booster with master cylinder assembly)

| Comes on |

- INF Code 533: SAE Code C050E and C050F

- INF Code 536: SAE Code C14E7 (Case 1)

- INF Code 538: SAE Code C14E7 (Case 2)

- ABS DTC

| MONITOR DESCRIPTION

The

skid control ECU (brake booster with master cylinder assembly) monitors

the output voltage and power supply voltage of the speed sensors. If

the output voltage of the speed sensor is outside the normal range, or

if the voltage at VM1 of the skid control ECU (brake booster with master

cylinder assembly) is normal and the power supply voltage of the speed

sensor drops below a specific value, the skid control ECU (brake booster

with master cylinder assembly) judges that the circuit of the speed

sensor is malfunctioning and illuminates the MIL and stores a DTC. MONITOR STRATEGY |

Related DTCs | C050E: Speed sensor circuit low C050F: Speed sensor circuit high

C0514: Speed sensor circuit low C0515: Speed sensor circuit high

C14E7 (Case 1): Speed sensor voltage circuit low C14E7 (Case 2): Speed sensor voltage circuit low

C14EA (Case 1): Speed sensor voltage circuit low C14EA (Case 2): Speed sensor voltage circuit low | |

Required Sensors/Components(Main) | Speed sensor

Skid control ECU (brake booster with master cylinder assembly) | |

Required Sensors/Components(Related) | Speed sensor

Skid control ECU (brake booster with master cylinder assembly) | |

Frequency of Operation | Continuous | |

Duration | 0.5 seconds: C050E, C050F, C0514, C0515, C14E7 (Case 1) and C14EA (Case 1)

60 seconds: C14E7 (Case 2) and C14EA (Case 2) | |

MIL Operation | Immediately | |

Sequence of Operation | None | TYPICAL ENABLING CONDITIONS C050E, C050F, C0514 and C0515 |

Monitor runs whenever the following DTCs are not stored |

C14E1, C14E4, C14E7, C14EA(Case 1) (Speed sensor voltage circuit low)

C14E1, C14E4, C14E7, C14EA(Case 2) (Speed sensor voltage circuit low) | |

All of the following conditions are met | - | |

Brake system voltage 1 (VM1) | Higher than 7.54 V | |

Serial communication with low side IC | Valid | |

Command to speed sensor power supply |

On | | Speed sensor fail (C14E1, C14E4, C14E7, C14EA) |

Not detected | C14E7 and C14EA (Case 1) |

Monitor runs whenever the following DTCs are not stored |

C0502, C0508, C050E, C0514 (Speed sensor circuit low) C0503, C0509, C050F, C0515 (Speed sensor circuit high)

C14E1, C14E4, C14E7, C14EA (Case 2) (Speed sensor voltage circuit low) | |

All of the following conditions are met | - | |

Brake system voltage 1 (VM1) | Higher than 7.54 V | |

Serial communication with low side IC | Valid | |

Command to speed sensor power supply |

On | | Speed

sensor fail (C0502, C0503, C0508, C0509, C050E, C050F, C0514, C0515,

C14E1 (Case 2), C14E4 (Case 2), C14E7 (Case 2), C14EA (Case 2)) |

Not detected | C14E7 and C14EA (Case 2) |

Monitor runs whenever the following DTCs are not stored |

C0502, C0508, C050E, C0514 (Speed sensor circuit low) C0503, C0509, C050F, C0515 (Speed sensor circuit high)

C14E1, C14E4, C14E7, C14EA (Case 1) (Speed sensor voltage circuit low) | |

All of the following conditions are met | - | |

Brake system voltage 1 (VM1) | Higher than 7.54 V | |

Serial communication with low side IC | Valid | |

Command to speed sensor power supply |

On | | Speed

sensor fail (C0502, C0503, C0508, C0509, C050E, C050F, C0514, C0515,

C14E1 (Case 1), C14E4 (Case 1), C14E7 (Case 1), C14EA (Case 1)) |

Not detected | TYPICAL MALFUNCTION THRESHOLDS C050E and C0514 |

Speed sensor voltage | Less than 0.4 V | C050F and C0515 |

Speed sensor voltage | Higher than 3.3 V | C14E7 and C14EA (Case 1) |

Speed sensor power supply voltage | Less than 6.1 V | C14E7 and C14EA (Case 2) |

The speed sensor power supply voltage drops below 6.1 V for 0.2 seconds or more |

Met | COMPONENT OPERATING RANGE C050E, C050F, C0514 and C0515 |

Both of the following conditions are met |

- | | Serial communication with low side IC |

Valid | | Speed sensor voltage |

0.4 V or more, and 3.3 V or less | C14E7 and C14EA (Case 1) |

Both of the following conditions are met |

- | | Serial communication with low side IC |

Valid | | Speed sensor power supply voltage |

6.1 V or more | C14E7 and C14EA (Case 2) |

All of the following conditions are met |

- | | Brake system voltage 1 (VM1) |

Higher than 7.54 V | |

Serial communication with low side IC |

Valid | | Command to speed sensor power supply |

On | | Speed

sensor fail (C0502, C0503, C0508, C0509, C050E, C050F, C0514, C0515,

C14E1 (Case 1), C14E4 (Case 1), C14E7 (Case 1), C14EA (Case 1)) |

Not detected | | The speed sensor power supply voltage drops below 6.1 V for 0.2 seconds or more |

Not met | CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Wait 60 seconds.

- Enter the following menus: Chassis / ABS/VSC/TRAC / Trouble Codes.

- Read the DTCs.

HINT:

- If a DTC is output, the system is malfunctioning.

- If a DTC is not output, perform the following procedure.

- If the DTCs are not output, perform a universal trip and check for permanent DTCs.

Click here

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTCs are output, the system is normal.

WIRING DIAGRAM Refer to DTCs C1415 and C1416.

Click here  CAUTION / NOTICE / HINT

NOTICE:

- After replacing the skid control ECU (brake booster with master cylinder

assembly), perform linear solenoid valve offset learning, ABS holding

solenoid valve learning, yaw rate and acceleration sensor zero point

calibration and system information memorization after performing "Reset

Memory".

Click here

- Disassembly of the rear speed sensor from the rear axle hub and bearing assembly is prohibited.

PROCEDURE (a) Clear the DTCs.

Click here  Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off. (c) Turn the power switch on (IG).

(d) Check if the same DTC is output. Click here

Chassis > ABS/VSC/TRAC > Trouble Codes

| Result |

Proceed to | | DTC C1407 is output. |

A | | DTC C1408 is output. |

B |

| B |

| GO TO STEP 8 |

|

A |

| |

| 2. |

READ VALUE USING TECHSTREAM (MOMENTARY INTERRUPTION) |

(a) Using the Techstream, check for any momentary interruptions in the wire harness and connector corresponding to a DTC.

Click here  Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note | |

RR Speed Open | Rear speed sensor RH open detection |

Error or Normal | Error: Momentary interruption

Normal: Normal | - | Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | | RR Speed Open |

(b) Check for any momentary interruptions in the wire harness and connectors.

OK: There are no momentary interruptions. NOTICE: Perform the above inspection before removing the sensor and connector.

| NG |

| GO TO STEP 5 |

|

OK |

| |

| 3. |

READ VALUE USING TECHSTREAM (REAR SPEED SENSOR RH) |

(a) Select the Data List on the Techstream. Click here

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note | |

RR Wheel Speed | Rear speed sensor RH |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations | Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | | RR Wheel Speed |

(b) Check the rear speed sensor RH output value. OK: The output value changes in accordance with the vehicle speed.

| NG |

| GO TO STEP 5 |

|

OK |

| |

(a) Clear the DTCs.

Click here  Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off. (c) Turn the power switch on (READY).

(d) Perform a road test. (e) Check if the same DTC is output. Click here

Chassis > ABS/VSC/TRAC > Trouble Codes

| Result |

Proceed to | | DTC C1407 is not output. |

A | | DTC C1407 is output. |

B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY |

| 5. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

| (a) Turn the power switch off. |

|

|

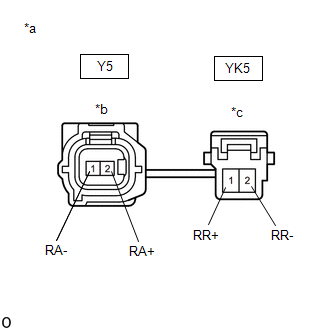

*a | Front view of skid control sensor wire RH (No. 1 parking brake wire assembly) | |

*b | Front view of wire harness connector

(to Sensor Side Connector) | |

*c | Front view of wire harness connector

(to Vehicle Side Connector) | | |

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK: The connector is securely connected. (c) Disconnect the Y5 and YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connectors.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (e) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

Y5-2 (RA+) - YK5-1 (RR+) |

Always | Below 1 Ω | |

Y5-2 (RA+) or YK5-1 (RR+) - Body ground and other terminals |

Always | 10 kΩ or higher | |

Y5-1 (RA-) - YK5-2 (RR-) |

Always | Below 1 Ω | |

Y5-1 (RA-) or YK5-2 (RR-) - Body ground and other terminals |

Always | 10 kΩ or higher |

| NG |

| REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

OK |

| |

| 6. |

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - NO. 1 PARKING BRAKE WIRE ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK: The connector is securely connected. (b) Disconnect the A35 skid control ECU (brake booster with master cylinder assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (d) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A35-7 (RR+) - YK5-1 (RR+) |

Always | Below 1 Ω | |

A35-7 (RR+) or YK5-1 (RR+) - Body ground |

Always | 10 kΩ or higher | |

A35-8 (RR-) - YK5-2 (RR-) |

Always | Below 1 Ω | |

A35-8 (RR-) or YK5-2 (RR-) - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 7. |

INSPECT BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY (SENSOR OUTPUT) |

| (a) Reconnect the A35 skid control ECU (brake booster with master cylinder assembly) connector. |

|

|

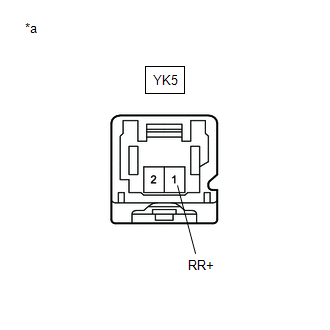

*a | Front view of wire harness connector

(to Skid Control Sensor Wire RH (No. 1 Parking Brake Wire Assembly)) | | |

(b) Turn the power switch on (IG). (c) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

YK5-1 (RR+) - Body ground |

Power switch on (IG) |

8 to 14 V | NOTICE: Check the rear speed sensor RH signal after replacement.

Click here  HINT: The rear speed sensor RH and rear speed sensor rotor RH are incorporated into the rear axle hub and bearing assembly RH.

If

the rear speed sensor RH and rear speed sensor rotor RH need to be

replaced, replace the rear axle hub and bearing assembly RH.

| OK |

| REPLACE REAR AXLE HUB AND BEARING ASSEMBLY RH |

| NG |

| REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY |

| 8. |

READ VALUE USING TECHSTREAM (MOMENTARY INTERRUPTION) |

(a) Using the Techstream, check for any momentary interruptions in the wire harness and connector corresponding to a DTC.

Click here  Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note | |

RL Speed Open | Rear speed sensor LH open detection |

Error or Normal | Error: Momentary interruption

Normal: Normal | - | Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | | RL Speed Open |

(b) Check for any momentary interruptions in the wire harness and connectors.

OK: There are no momentary interruptions. NOTICE: Perform the above inspection before removing the sensor and connector.

| NG |

| GO TO STEP 11 |

|

OK |

| |

| 9. |

READ VALUE USING TECHSTREAM (REAR SPEED SENSOR LH) |

(a) Select the Data List on the Techstream. Click here

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note | |

RL Wheel Speed | Rear speed sensor LH |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations | Chassis > ABS/VSC/TRAC > Data List

|

Tester Display | | RL Wheel Speed |

(b) Check the rear speed sensor LH output value. OK: The output value changes in accordance with the vehicle speed.

| NG |

| GO TO STEP 11 |

|

OK |

| |

(a) Clear the DTCs.

Click here  Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off. (c) Turn the power switch on (READY).

(d) Perform a road test. (e) Check if the same DTC is output. Click here

Chassis > ABS/VSC/TRAC > Trouble Codes

| Result |

Proceed to | | DTC C1408 is not output. |

A | | DTC C1408 is output. |

B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY |

| 11. |

INSPECT NO. 2 PARKING BRAKE WIRE ASSEMBLY |

| (a) Turn the power switch off. |

|

|

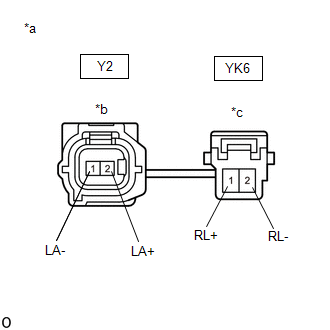

*a | Front view of skid control sensor wire LH (No. 2 parking brake wire assembly) | |

*b | Front view of wire harness connector

(to Sensor Side Connector) | |

*c | Front view of wire harness connector

(to Vehicle Side Connector) | | |

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK: The connector is securely connected. (c) Disconnect the Y2 and YK6 skid control sensor wire LH (No. 2 parking brake wire assembly) connectors.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (e) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

Y2-2 (LA+) - YK6-1 (RL+) |

Always | Below 1 Ω | |

Y2-2 (LA+) or YK6-1 (RL+) - Body ground and other terminals |

Always | 10 kΩ or higher | |

Y2-1 (LA-) - YK6-2 (RL-) |

Always | Below 1 Ω | |

Y2-1 (LA-) or YK6-2 (RL-) - Body ground and other terminals |

Always | 10 kΩ or higher |

| NG |

| REPLACE NO. 2 PARKING BRAKE WIRE ASSEMBLY |

|

OK |

| |

| 12. |

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - NO. 2 PARKING BRAKE WIRE ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK: The connector is securely connected. (b) Disconnect the A35 skid control ECU (brake booster with master cylinder assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (d) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A35-34 (RL+) - YK6-1 (RL+) |

Always | Below 1 Ω | |

A35-34 (RL+) or YK6-1 (RL+) - Body ground |

Always | 10 kΩ or higher | |

A35-35 (RL-) - YK6-2 (RL-) |

Always | Below 1 Ω | |

A35-35 (RL-) or YK6-2 (RL-) - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 13. |

INSPECT BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY (SENSOR OUTPUT) |

| (a) Reconnect the A35 skid control ECU (brake booster with master cylinder assembly) connector. |

|

|

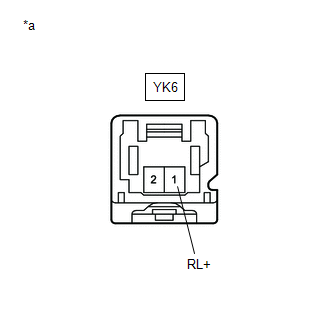

*a | Front view of wire harness connector

(to Skid Control Sensor Wire LH (No. 2 Parking Brake Wire Assembly)) | | |

(b) Turn the power switch on (IG). (c) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

YK6-1 (RL+) - Body ground |

Power switch on (IG) |

8 to 14 V | NOTICE: Check the rear speed sensor LH signal after replacement.

Click here  HINT: The rear speed sensor LH and rear speed sensor rotor LH are incorporated into the rear axle hub and bearing assembly LH.

If

the rear speed sensor LH and rear speed sensor rotor LH need to be

replaced, replace the rear axle hub and bearing assembly LH.

| OK |

| REPLACE REAR AXLE HUB AND BEARING ASSEMBLY LH |

| NG |

| REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY | |