DESCRIPTION Refer to DTC P012011. Click here

MONITOR DESCRIPTION The ECM uses the throttle position sensor to monitor the throttle valve opening angle. If the VTA2 terminal voltage is higher than the threshold, the ECM will illuminate the MIL and store this DTC. MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

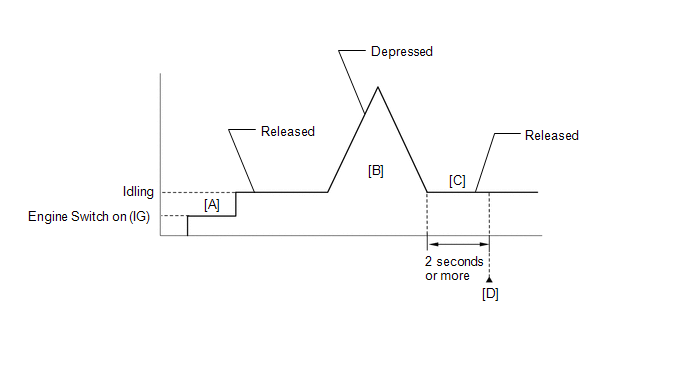

CONFIRMATION DRIVING PATTERN HINT:

FAIL-SAFE When this DTC is stored, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to the throttle actuator, and the throttle valve is returned to a 7° throttle valve opening angle by the return spring. The ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition timing, in accordance with the accelerator pedal angle, to allow the vehicle to continue running at a minimal speed. If the accelerator pedal is depressed firmly and gently, the vehicle can be driven slowly. Fail-safe mode continues until a pass condition is detected, and the engine switch is turned off. WIRING DIAGRAM Refer to DTC P012011. Click here CAUTION / NOTICE / HINT HINT: Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred. PROCEDURE

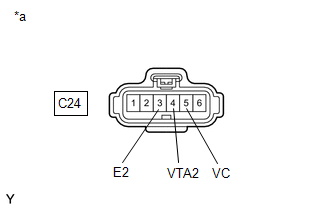

(a) Disconnect the throttle body with motor assembly connector. (b) Disconnect the ECM connector. (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

(a) Disconnect the throttle body with motor assembly connector. (b) Turn the engine switch on (IG). (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

(a) Disconnect the throttle body with motor assembly connector. (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

(a) Disconnect the throttle body with motor assembly connector. (b) Connect the Techstream to the DLC3. (c) Turn the engine switch on (IG). (d) Turn the Techstream on. (e) Enter the following menus: Powertrain / Engine / Data List / Throttle Position Sensor No.2 Voltage. Powertrain > Engine > Data List

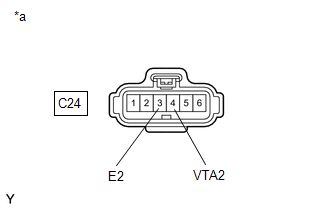

(f) According to the display on the Techstream, read the Data List. HINT: Use the snapshot function to record the value displayed or make a note of it. (g) Turn the engine switch off. (h) Turn the Techstream off. (i) Connect terminals 4 (VTA2) and 3 (E2) of the throttle body with motor assembly connector on the wire harness side. NOTICE: If the VTA2 terminal voltage or the resistance between VTA2 and E2 is abnormal and terminals 4 (VTA2) and 3 (E2) of the throttle body with motor assembly connector are connected, excessive current may flow through the circuit. In this case, do not connect the terminals. (j) Turn the engine switch on (IG). (k) Turn the Techstream on. (l) Enter the following menus: Powertrain / Engine / Data List / Throttle Position Sensor No.2 Voltage. Powertrain > Engine > Data List

(m) Compare the vehicle of the Data List item Throttle Position Sensor No.2 Voltage after the circuit is shorted to the value when the throttle body with motor assembly connector was connected.

HINT: Perform "Inspection After Repair" after replacing the throttle body with motor assembly. Click here

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Wiper And Washer System(for Gasoline Model): Diagnostic Trouble Code Chart

DIAGNOSTIC TROUBLE CODE CHART Wiper and Washer System DTC No. Detection Item DTC Output from Link B1245 Lost Communication with Wiper ECU LIN Main body ECU (multiplex network body ECU) B1370 ECU Malfunction Windshield wiper motor assembly B1372 Wiper Switch Signal Mismatch between LIN and Line Winds ...