DESCRIPTION Refer to DTC P032511. Click here

HINT: When

DTC P032515 or P033015 is stored, the ECM enters fail-safe mode. During

fail-safe mode, the ignition timing is delayed to its maximum

retardation. Fail-safe mode continues until the engine switch is turned

off. |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Memory |

Note | | P032515 |

Knock Sensor 1 Bank 1 or Single Sensor Circuit Short to Battery or Open |

The knock control sensor (bank 1) output voltage is higher than 4.5 V for 1 second or more (1 trip detection logic). |

- Open or short in knock control sensor (bank 1) circuit

- Knock control sensor (bank 1)

- ECM

| Comes on |

DTC stored | SAE Code: P0328 | |

P033015 | Knock Sensor 2 Bank 2 Circuit Short to Battery or Open |

The knock control sensor (bank 2) output voltage is higher than 4.5 V for 1 second or more (1 trip detection logic). |

- Open or short in knock control sensor (bank 2) circuit

- Knock control sensor (bank 2)

- ECM

| Comes on |

DTC stored | SAE Code: P0333 |

Reference: Inspection using an oscilloscope. Click here

MONITOR DESCRIPTION

If

the output voltage transmitted by the knock control sensor remains high

for 1 second or more, the ECM interprets this as a malfunction in the

sensor circuit, and stores this DTC. MONITOR STRATEGY |

Related DTCs | P0328: Knock control sensor (bank 1) range check (high voltage)

P0333: Knock control sensor (bank 2) range check (high voltage) | |

Required Sensors/Components (Main) | Knock control sensor | |

Required Sensors/Components (Related) | - | |

Frequency of Operation | Continuous | |

Duration | 1 second | | MIL Operation |

Immediate | | Sequence of Operation |

None | TYPICAL ENABLING CONDITIONS |

Monitor runs whenever the following DTCs are not stored |

None | | Both of the following conditions are met |

- | | Battery voltage |

10.5 V or higher | | Time after engine start |

5 seconds or more | TYPICAL MALFUNCTION THRESHOLDS |

Knock control sensor voltage | Higher than 4.5 V | CONFIRMATION DRIVING PATTERN

HINT:

- After repair has been completed, clear the DTC and then check that the

vehicle has returned to normal by performing the following All Readiness

check procedure.

Click here

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for at least 30 seconds.

- Start the engine and wait 5 minutes [A].

- Turn the Techstream on.

- Enter the following menus: Powertrain / Engine / Trouble Codes [B].

- Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P032515 or P033015.

- Check the DTC judgment result.

|

Techstream Display |

Description |

|

NORMAL |

- DTC judgment completed

- System normal

|

|

ABNORMAL |

- DTC judgment completed

- System abnormal

|

|

INCOMPLETE |

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

HINT:

WIRING DIAGRAM Refer to DTC P032511. Click here

CAUTION / NOTICE / HINT

HINT:

PROCEDURE |

1. | CHECK TERMINAL VOLTAGE (POWER SOURCE OF KNOCK CONTROL SENSOR) |

|

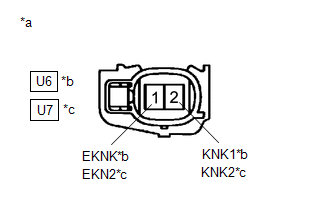

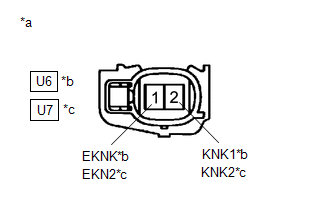

*a | Front view of wire harness connector

(to Knock Control Sensor) | |

*b | Bank 1 | |

*c | Bank 2 |

(a) Disconnect the knock control sensor connector. (b) Turn the engine switch on (IG).

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

U6-1 (EKNK) - U6-2 (KNK1) |

Engine switch on (IG) |

4.5 to 5.5 V | |

U7-1 (EKN2) - U7-2 (KNK2) |

Engine switch on (IG) |

4.5 to 5.5 V |

| NG |

| GO TO STEP 3 |

|

OK |

| |

| 2. |

INSPECT KNOCK CONTROL SENSOR | (a) Inspect the knock control sensor.

Click here  HINT: Perform "Inspection After Repair" after replacing the knock control sensor.

Click here

| OK |

| GO TO STEP 4 |

| NG |

| REPLACE KNOCK CONTROL SENSOR |

| 3. |

CHECK HARNESS AND CONNECTOR (KNOCK CONTROL SENSOR - ECM) |

(a) Disconnect the knock control sensor connector. (b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

U6-2 (KNK1) - C56-82 (KNK1) |

Always | Below 1 Ω | |

U6-1 (EKNK) - C56-81 (EKNK) |

Always | Below 1 Ω | |

U7-2 (KNK2) - C56-114 (KNK2) |

Always | Below 1 Ω | |

U7-1 (EKN2) - C56-113 (EKN2) |

Always | Below 1 Ω | |

U6-2 (KNK1) or C56-82 (KNK1) - Other terminals |

Always | 10 kΩ or higher | |

U7-2 (KNK2) or C56-114 (KNK2) - Other terminals |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG). (c) Turn the Techstream on.

(d) Clear the DTC. Powertrain > Engine > Clear DTCs (e) Turn the engine switch off and wait for at least 30 seconds.

|

NEXT |

| |

| 5. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P032515 OR P033015) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Trouble Codes. (c) Read the DTCs. Powertrain > Engine > Trouble Codes

|

Result | Proceed to | |

DTCs are not output | A | |

DTC P032515 or P033015 is output |

B |

| A |

| CHECK FOR INTERMITTENT PROBLEMS |

| B |

| REPLACE ECM | |