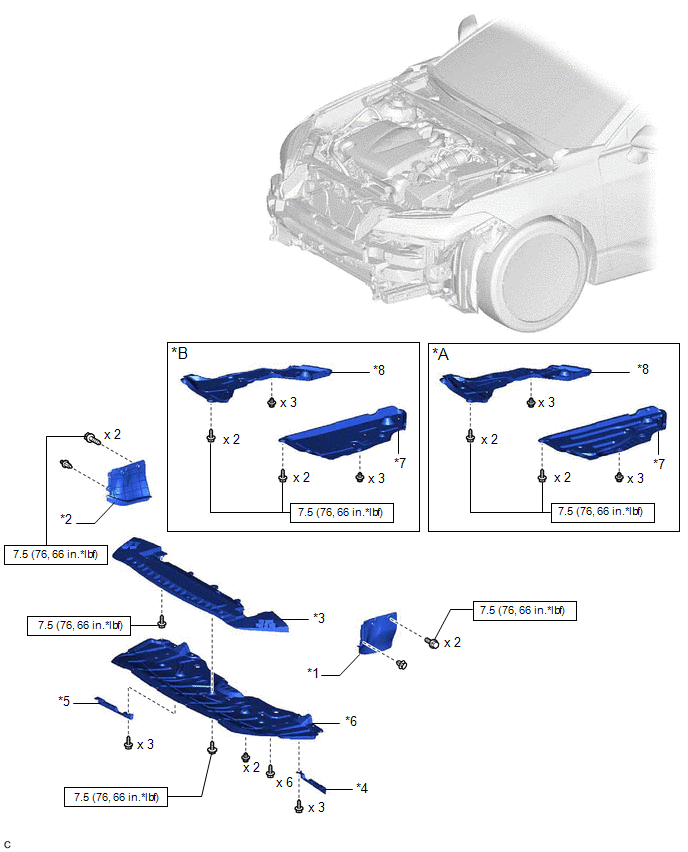

COMPONENTS

ILLUSTRATION

|

*A | Type A |

*B | Type B |

|

*1 | FRONT FENDER APRON SEAL LH |

*2 | FRONT FENDER APRON SEAL RH |

|

*3 | FRONT LOWER BUMPER ABSORBER |

*4 | FRONT WHEEL OPENING EXTENSION PAD LH |

|

*5 | FRONT WHEEL OPENING EXTENSION PAD RH |

*6 | NO. 1 ENGINE UNDER COVER |

|

*7 | REAR ENGINE UNDER COVER LH |

*8 | REAR ENGINE UNDER COVER RH |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

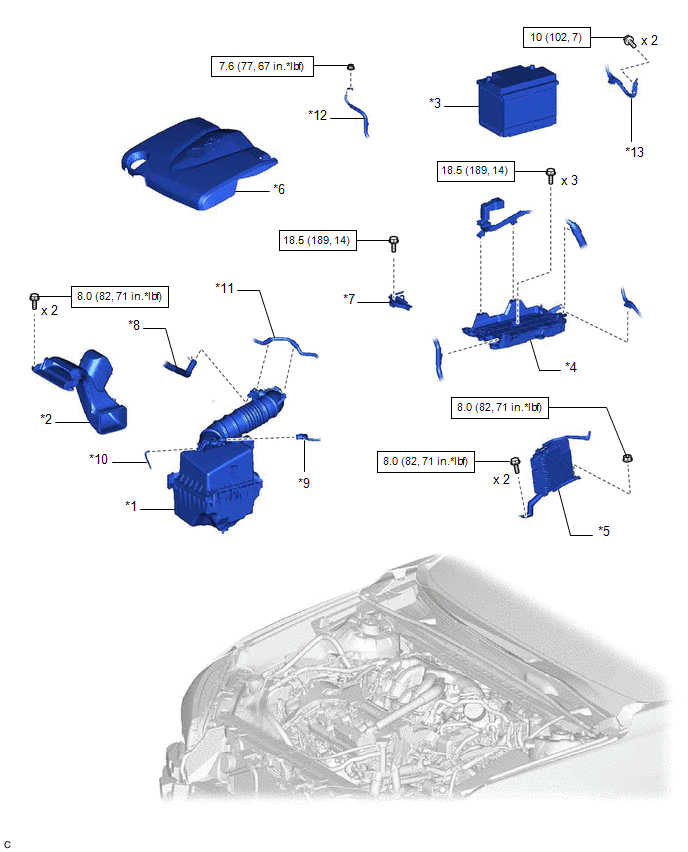

ILLUSTRATION

|

*1 | AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE |

*2 | INLET AIR CLEANER ASSEMBLY |

|

*3 | BATTERY |

*4 | BATTERY CLAMP SUB-ASSEMBLY |

|

*5 | ECM |

*6 | V-BANK COVER SUB-ASSEMBLY |

|

*7 | NO. 2 BATTERY CLAMP |

*8 | NO. 2 VENTILATION HOSE |

|

*9 | MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR |

*10 | VACUUM HOSE |

|

*11 | NO. 1 FUEL VAPOR FEED HOSE |

*12 | ENGINE ROOM MAIN WIRE |

|

*13 | EARTH WIRE |

- | - |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

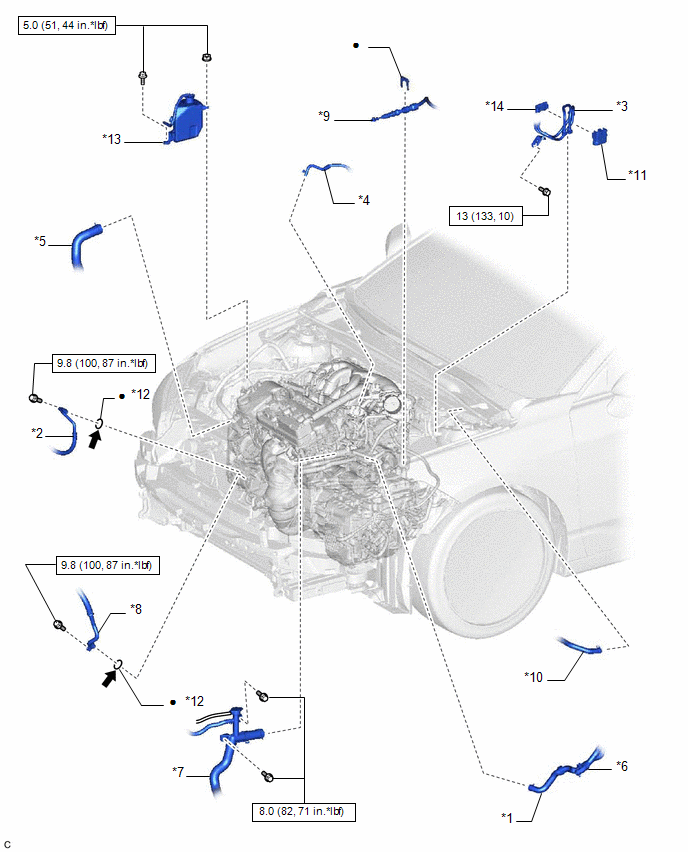

ILLUSTRATION

|

*1 | INLET HEATER WATER HOSE |

*2 | NO. 1 COOLER REFRIGERANT DISCHARGE HOSE SUB-ASSEMBLY |

|

*3 | NO. 1 FUEL HOSE |

*4 | NO. 1 FUEL VAPOR FEED HOSE |

|

*5 | NO. 2 RADIATOR HOSE |

*6 | OUTLET HEATER WATER HOSE |

|

*7 | RADIATOR HOSE SUB-ASSEMBLY |

*8 | SUCTION HOSE SUB-ASSEMBLY |

|

*9 | TRANSMISSION CONTROL CABLE ASSEMBLY |

*10 | UNION TO CHECK VALVE HOSE |

|

*11 | NO. 1 FUEL PIPE CLAMP |

*12 | O-RING |

|

*13 | RADIATOR RESERVE TANK ASSEMBLY |

*14 | NO. 2 FUEL PIPE CLAMP |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

|

Compressor oil ND-OIL 12 or equivalent |

- | - |

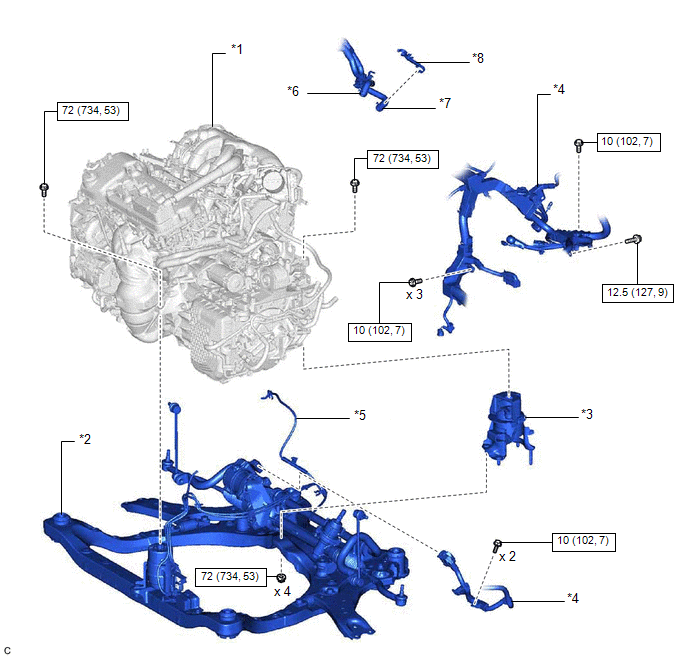

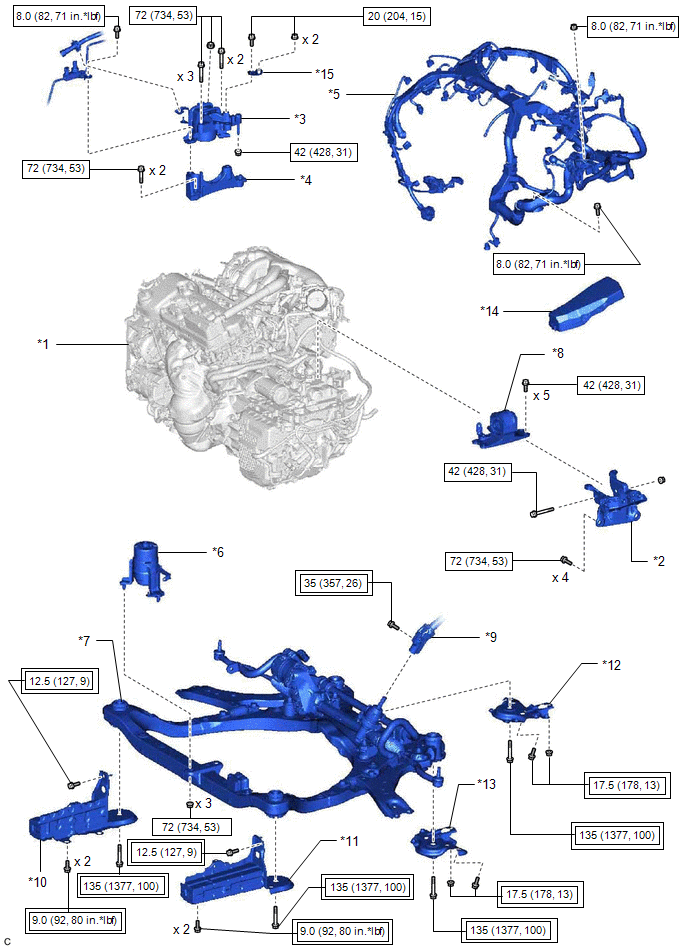

ILLUSTRATION

|

*1 | ENGINE ASSEMBLY WITH TRANSAXLE |

*2 | FRONT FRAME ASSEMBLY |

|

*3 | REAR ENGINE MOUNTING INSULATOR |

*4 | WIRE HARNESS |

|

*5 | VACUUM HOSE |

*6 | NO. 1 WATER BY-PASS HOSE |

|

*7 | WATER BY-PASS HOSE ASSEMBLY |

*8 | TRANSMISSION BREATHER CLAMP |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

ILLUSTRATION

|

*1 | ENGINE ASSEMBLY WITH TRANSAXLE |

*2 | ENGINE MOUNTING BRACKET SUB-ASSEMBLY LH |

|

*3 | ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

*4 | ENGINE MOUNTING SPACER |

|

*5 | ENGINE WIRE |

*6 | FRONT ENGINE MOUNTING INSULATOR |

|

*7 | FRONT FRAME ASSEMBLY |

*8 | ENGINE MOUNTING INSULATOR LH |

|

*9 | STEERING INTERMEDIATE SHAFT ASSEMBLY |

*10 | FRONT BUMPER EXTENSION SUB-ASSEMBLY RH |

|

*11 | FRONT BUMPER EXTENSION SUB-ASSEMBLY LH |

*12 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY RH |

|

*13 | FRONT SUSPENSION MEMBER BRACKET SUB-ASSEMBLY LH |

*14 | NO. 2 RELAY BLOCK COVER |

|

*15 | NO. 2 ENGINE MOUNTING STAY RH |

- | - |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

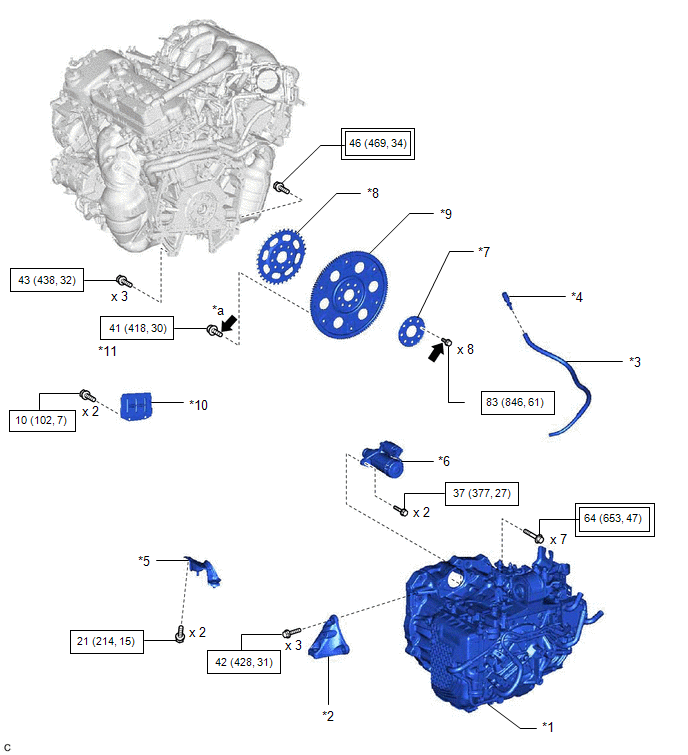

ILLUSTRATION

|

*1 | AUTOMATIC TRANSAXLE ASSEMBLY |

*2 | FRONT ENGINE MOUNTING BRACKET |

|

*3 | BREATHER PLUG HOSE |

*4 | BREATHER PLUG SUB-ASSEMBLY |

|

*5 | NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Upper Side) |

*6 | STARTER ASSEMBLY |

|

*7 | REAR DRIVE PLATE SPACER |

*8 | NO. 1 CRANKSHAFT POSITION SENSOR PLATE |

|

*9 | DRIVE PLATE AND RING GEAR SUB-ASSEMBLY |

*10 | FLYWHEEL HOUSING UNDER COVER |

|

*11 | DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT |

- | - |

|

*a | BLACK COLOR: x 1 SILVER COLOR: x 5 | - |

- |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

|

Adhesive 1324 | ★ |

Precoated part |

INSTALLATION

CAUTION / NOTICE / HINT

CAUTION:

PROCEDURE

1. INSTALL ENGINE MOUNTING INSULATOR LH

HINT:

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

Click here

2. INSTALL ENGINE MOUNTING BRACKET SUB-ASSEMBLY LH

HINT:

Perform this procedure only when replacement of the engine mounting bracket sub-assembly LH is necessary.

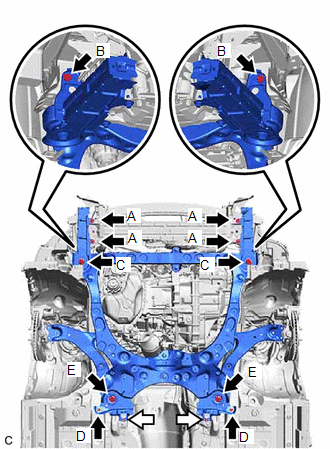

| (a) Temporarily tighten the bolt (A), and then fully tighten the 4 bolts in the order of (B), (C), (D) and (A). Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Make sure that there is no gap between the engine mounting bracket sub-assembly LH and vehicle body before tightening the bolts. |

|

3. INSTALL ENGINE MOUNTING SPACER

HINT:

Perform this procedure only when replacement of the engine mounting spacer is necessary.

| (a) Install the engine mounting spacer to the vehicle body with the 2 bolts. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts in the order of (B) and (A). |

|

4. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

HINT:

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

| (a) Install the engine mounting insulator sub-assembly RH to the engine mounting spacer and vehicle body with the nut and 2 bolts. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts and nut in the order of (B), (A) and (C). |

|

(b) Engage the clamp.

(c) Install the bracket to the engine mounting insulator sub-assembly RH with the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

| (d) Install the radiator reserve tank assembly with the bolt and nut in the order shown in the illustration. Torque: 5.0 N·m {51 kgf·cm, 44 in·lbf} |

|

(e) Engage the clamp.

5. INSTALL ENGINE HANGERS

Click here

6. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

(a) Remove the engine assembly from the engine stand.

7. INSTALL CRANKSHAFT POSITION SENSOR PLATE NO.1

Click here

8. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

Click here

9. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY

Click here

10. INSTALL FRONT ENGINE MOUNTING BRACKET

Click here

11. INSTALL REAR ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the rear engine mounting insulator is necessary.

Click here

12. INSTALL FRONT ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

(a) Install the front engine mounting insulator to the front frame assembly with the 3 nuts.

Torque:

72 N·m {734 kgf·cm, 53 ft·lbf}

13. INSTALL FRONT FRAME ASSEMBLY

(a) Install the rear engine mounting insulator to the front frame assembly with the 4 nuts.

Torque:

72 N·m {734 kgf·cm, 53 ft·lbf}

(b) Install the front engine mounting insulator to the front engine mounting bracket with the bolt.

Torque:

72 N·m {734 kgf·cm, 53 ft·lbf}

14. REMOVE ENGINE HANGERS

Click here

15. INSTALL ENGINE WIRE

(a) Connect all connectors and clamps, and install the engine wire to the engine assembly with transaxle.

16. CONNECT WATER BY-PASS HOSE ASSEMBLY

Click here

17. CONNECT NO. 1 WATER BY-PASS HOSE

Click here

18. INSTALL BREATHER PLUG HOSE

Click here

19. INSTALL STARTER ASSEMBLY

Click here

20. CONNECT VACUUM HOSE

Click here

21. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

Perform Inspection After Repair after replacing the engine assembly.

Click here

(a) Using height adjustment attachments and plate lift attachments to keep the engine assembly with transaxle and front frame assembly level, set an engine lifter underneath the engine assembly with transaxle and front frame assembly.

NOTICE:

(b) Operate the engine lifter and install the engine assembly with transaxle to the vehicle.

CAUTION:

Do not raise the engine assembly with transaxle more than necessary. If the engine is raised excessively, the vehicle may also be lifted up.

NOTICE:

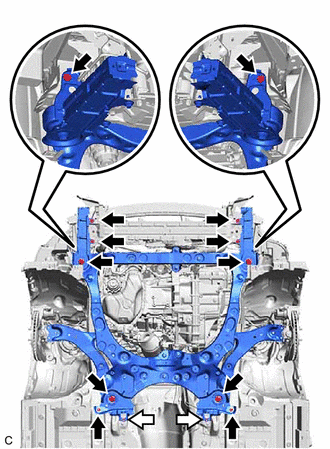

(c) Install the front bumper extension sub-assembly RH and front bumper extension sub-assembly LH to the front frame assembly and vehicle body with the 8 bolts.

|

Bolt |

|

Nut |

Torque:

Bolt (A) :

9.0 N·m {92 kgf·cm, 80 in·lbf}

Bolt (B) :

12.5 N·m {127 kgf·cm, 9 ft·lbf}

Bolt (C) :

135 N·m {1377 kgf·cm, 100 ft·lbf}

(d) Install the front suspension member bracket sub-assembly RH and front suspension member bracket sub-assembly LH to the front frame assembly and vehicle body with the 4 bolts and 2 nuts.

Torque:

Bolt (D) :

17.5 N·m {178 kgf·cm, 13 ft·lbf}

Bolt (E) :

135 N·m {1377 kgf·cm, 100 ft·lbf}

Nut :

17.5 N·m {178 kgf·cm, 13 ft·lbf}

(e) Install the engine mounting insulator LH to the engine mounting bracket sub-assembly LH with the bolt and nut.

Torque:

42 N·m {428 kgf·cm, 31 ft·lbf}

(f) Install the engine mounting insulator sub-assembly RH to the front No. 1 engine mounting bracket LH with the 3 bolts and nut.

Torque:

Bolt :

72 N·m {734 kgf·cm, 53 ft·lbf}

Nut :

42 N·m {428 kgf·cm, 31 ft·lbf}

(g) Install the No. 2 engine mounting stay RH with the bolt and 2 nuts.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

22. INSTALL DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

Click here

23. INSTALL FLYWHEEL HOUSING UNDER COVER

(a) Install the flywheel housing under cover with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

24. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Upper Side)

(a) Install the No. 1 exhaust pipe support bracket to the oil pan sub-assembly with the 2 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

25. INSTALL FRONT DRIVE SHAFT ASSEMBLY

Click here

26. INSTALL EXHAUST MANIFOLD

Click here

27. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY

Click here

28. CONNECT EARTH WIRE

(a) Connect the earth wire to the vehicle body with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

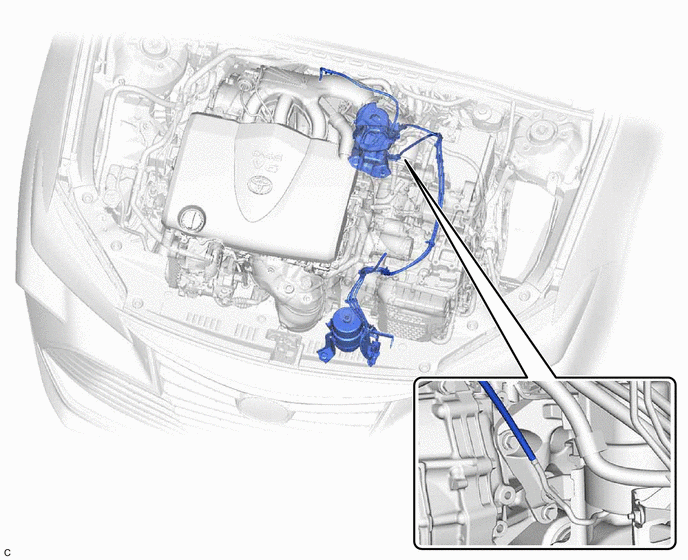

29. CONNECT ENGINE WIRE

(a) Engage the 2 clamps and connect the engine wire to the vehicle body.

(b) Connect the engine wire with the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(c) Engage the 2 clamps.

(d) Engage the claw and connect the engine wire to the engine room relay block and junction block assembly.

(e) Install the nut to the engine room relay block and junction block assembly.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(f) Connect the 4 connectors to the engine room relay block and junction block assembly.

(g) Install the No. 2 relay block cover to the engine room relay block and junction block assembly.

30. CONNECT SUCTION HOSE SUB-ASSEMBLY

Click here

31. CONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE SUB-ASSEMBLY

Click here

32. CONNECT NO. 1 FUEL HOSE

(a) Install the No. 1 fuel hose with the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

(b) Connect the No. 1 fuel hose (for Port Injection).

(1) Connect the No. 1 fuel hose to the fuel pipe.

Click here

(c) Connect the No. 1 fuel hose (for Direct Injection).

(1) Connect the No. 1 fuel hose to the fuel pipe.

Click here

(d) Install the No. 1 fuel pipe clamp to the fuel tube connector.

(e) Engage the 2 claws to install the No. 2 fuel pipe clamp.

33. CONNECT OUTLET HEATER WATER HOSE

(a) Connect the outlet heater water hose to the heater water pipe and slide the clip to secure it.

34. CONNECT INLET HEATER WATER HOSE

(a) Connect the inlet heater water hose to the water outlet and slide the clip to secure it.

(b) Engage the clamp.

35. CONNECT RADIATOR HOSE SUB-ASSEMBLY

(a) Connect the radiator hose sub-assembly to the water outlet and slide the clip to secure it.

(b) Install the radiator hose sub-assembly to the engine assembly with the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

36. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the water inlet and slide the clip to secure it.

37. CONNECT UNION TO CHECK VALVE HOSE

(a) Connect the union to check valve hose to the brake booster assembly and slide the clip to secure it.

38. CONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Connect the No. 1 fuel vapor feed hose to the No. 1 vacuum switching valve and slide the clip to secure it.

39. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

(a) Connect the transmission control cable assembly to the No. 1 transmission control cable bracket with a new clip.

| (b) Connect the transmission control cable assembly to the transmission control shaft lever as shown in the illustration. NOTICE: Before installing the transmission control cable assembly, check that the park/neutral position switch assembly and shift lever are in N. |

|

40. INSTALL BATTERY CLAMP SUB-ASSEMBLY

(a) Install the battery clamp sub-assembly with the 3 bolts.

Torque:

18.5 N·m {189 kgf·cm, 14 ft·lbf}

(b) Engage the 5 clamps to the battery clamp sub-assembly.

41. INSTALL BATTERY

Click here

42. CONNECT ENGINE ROOM MAIN WIRE

(a) Connect the engine wire with engine room main wire to the positive (+) battery terminal with the nut.

Torque:

7.6 N·m {77 kgf·cm, 67 in·lbf}

43. INSTALL ECM

Click here

44. INSTALL AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE

| (a) Install the air cleaner assembly with air cleaner hose to the throttle body with motor assembly. NOTICE: Align the cutout of the air cleaner hose assembly with the protrusion of the throttle body with motor assembly. |

|

(b) Tighten the hose clamp in the position shown in the illustration.

NOTICE:

Make sure that the end of the hose clamp is positioned as shown in the illustration.

| (c) Insert the 3 pins of the air cleaner assembly into the 3 air cleaner supports as shown in the illustration. NOTICE:

|

|

(d) Engage the vacuum hose to the air cleaner hose.

(e) Engage the 3 wire harness clamps.

(f) Connect the mass air flow meter sub-assembly connector.

| (g) Connect the No. 2 ventilation hose to the air cleaner hose and slide the clip to secure it. NOTICE: Make sure that the condition of the clip is as shown in the illustration. |

|

(h) Engage the 2 clamps to connect the No. 1 fuel vapor feed hose to the air cleaner hose.

45. INSTALL INLET AIR CLEANER ASSEMBLY

| (a) Install the inlet air cleaner assembly with the 2 bolts in the order shown in the illustration. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} |

|

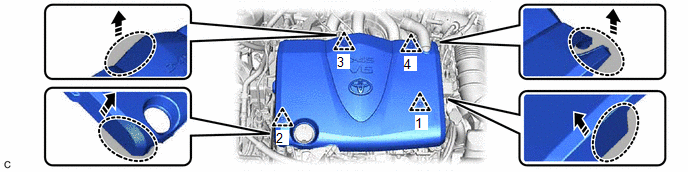

46. INSTALL V-BANK COVER SUB-ASSEMBLY

| (a) Engage the 4 clips in the order shown in the illustration to install the V-bank cover sub-assembly. NOTICE:

|

|

47. INSPECT VACUUM HOSES

(a) Inspect the vacuum hoses.

48. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here

49. ADD ENGINE OIL

Click here

50. ADD ENGINE COOLANT

Click here

51. ADD AUTOMATIC TRANSAXLE FLUID

Click here

52. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

Click here

53. WARM UP ENGINE

Click here

54. INSPECT SHIFT LEVER POSITION

Click here

55. ADJUST SHIFT LEVER POSITION

Click here

56. INSPECT FOR ENGINE OIL LEAK

Click here

57. INSPECT FOR COOLANT LEAK

Click here

58. INSPECT FOR REFRIGERANT LEAK

Click here

59. INSPECT FOR FUEL LEAK

Click here

60. INSPECT FOR EXHAUST GAS LEAK

Click here

61. CHECK ENGINE OIL LEVEL

Click here

62. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR TANK

Click here

63. INSTALL FRONT LOWER BUMPER ABSORBER

(a) Engage the 2 claws to the front lower bumper absorber.

(b) Install the 4 bolts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

64. INSTALL FRONT BUMPER COVER

Click here

65. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 screws and clip.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

66. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2 screws and clip.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

67. INSTALL REAR ENGINE UNDER COVER RH

(a) Install the rear engine under cover RH with the 2 screws and 3 clips.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

68. INSTALL REAR ENGINE UNDER COVER LH

(a) Install the rear engine under cover LH with the 2 screws and 3 clips.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

69. INSTALL NO. 1 ENGINE UNDER COVER

(a) Install the No. 1 engine under cover with the bolt, 6 screws and 2 clips.

Torque:

Bolt :

7.5 N·m {76 kgf·cm, 66 in·lbf}

70. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

(a) Install the front wheel opening extension pad LH with the 3 screws.

71. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

(a) Install the front wheel opening extension pad RH with the 3 screws.

72. INSTALL FRONT WHEELS

Click here

73. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

74. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Click here

75. PERFORM INITIALIZATION

Click here

76. INSPECT IGNITION TIMING

Click here

77. INSPECT ENGINE IDLE SPEED

Click here

78. INSPECT CO/HC

Click here

79. CHECK FOR SPEED SENSOR SIGNAL

Click here

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during engine assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system | |||

|

Intelligent Clearance Sonar System*1 | |||

|

Lighting System (for Gasoline Model with Cornering Light) | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic View Monitor System |

| ||

|

Replacement of ECM | Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

| |

| Inspection after repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If transaxle compensation code read from ECM) |

| ||

| Replacement of ECM (If transaxle compensation code not read from ECM) |

| ||

| Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

|

Replacement of ECM | Code registration (Smart Key System (for Start Function)) |

|

|

|

Suspension, tires, etc. |

|

|

|

|

Rear television camera assembly optical axis adjustment (Back camera position setting) |

Parking Assist Monitor System |

| |

| Panoramic View Monitor System |

| |

|

Perform headlight ECU sub-assembly LH initialization |

Lighting system (for Gasoline Model with Cornering Light) |

| |

|

Front wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

|

|

Click here

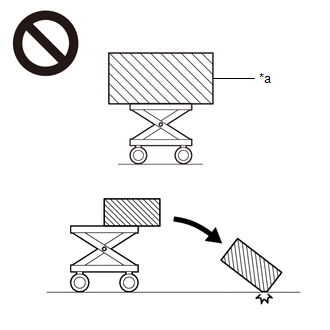

CAUTION:

|

*a |

An Object Exceeding Weight Limit of Engine Lifter |

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

Click here

3. DISCHARGE FUEL SYSTEM PRESSURE

Click here

4. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here

5. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

6. SECURE STEERING WHEEL

Click here

7. REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

(a) Remove the 3 screws and front wheel opening extension pad LH.

8. REMOVE FRONT WHEEL OPENING EXTENSION PAD RH

(a) Remove the 3 screws and front wheel opening extension pad RH.

9. REMOVE NO. 1 ENGINE UNDER COVER

(a) Remove the bolt, 2 clips, 6 screws and No. 1 engine under cover.

10. REMOVE REAR ENGINE UNDER COVER LH

(a) Remove the 2 screws, 3 clips and rear engine under cover LH.

11. REMOVE REAR ENGINE UNDER COVER RH

(a) Remove the 2 screws, 3 clips and rear engine under cover RH.

12. REMOVE FRONT FENDER APRON SEAL LH

(a) Remove the 2 screws, clip and front fender apron seal LH from the vehicle body.

13. REMOVE FRONT FENDER APRON SEAL RH

(a) Remove the 2 screws, clip and front fender apron seal RH from the vehicle body.

14. REMOVE FRONT BUMPER COVER

Click here

15. REMOVE FRONT LOWER BUMPER ABSORBER

| (a) Remove the 4 bolts. |

|

(b) Disengage the 2 claws to remove the front lower bumper absorber.

16. DRAIN ENGINE COOLANT

Click here

17. DRAIN ENGINE OIL

Click here

18. DRAIN AUTOMATIC TRANSAXLE FLUID

Click here

19. REMOVE V-BANK COVER SUB-ASSEMBLY

(a) Disengage the 4 clips in the order shown in the illustration and lift the V-bank cover sub-assembly upward to remove it.

| Hold here |

|

Pull in this Direction |

NOTICE:

20. REMOVE INLET AIR CLEANER ASSEMBLY

| (a) Remove the 2 bolts and inlet air cleaner assembly. |

|

21. REMOVE AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE

| (a) Disengage the 2 clamps to disconnect the No. 1 fuel vapor feed hose from the air cleaner hose. |

|

(b) Slide the clip and disconnect the No. 2 ventilation hose from the air cleaner hose.

| (c) Loosen the hose clamp. |

|

| (d) Disconnect the mass air flow meter sub-assembly connector. |

|

(e) Disengage the 3 wire harness clamps.

(f) Disconnect the vacuum hose from the air cleaner hose.

(g) Disengage the 3 pins and remove the air cleaner assembly with air cleaner hose.

NOTICE:

Make sure the air cleaner support remains attached to the vehicle body.

22. REMOVE ECM

Click here

23. DISCONNECT ENGINE ROOM MAIN WIRE

| (a) Remove the nut and disconnect the engine wire with engine room main wire from the positive (+) battery terminal. |

|

24. REMOVE BATTERY

Click here

25. REMOVE BATTERY CLAMP SUB-ASSEMBLY

| (a) Disengage the 5 clamps from the battery clamp sub-assembly. |

|

(b) Remove the 3 bolts and battery clamp sub-assembly.

26. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

| (a) While disengaging the clip as shown in the illustration, disconnect the transmission control cable assembly from the transmission control shaft lever together with the clip. |

|

| (b) Remove the clip and disconnect the transmission control cable assembly from the No. 1 transmission control cable bracket. |

|

27. DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

| (a) Slide the clip and disconnect the No. 1 fuel vapor feed hose from the No. 1 vacuum switching valve assembly. |

|

28. DISCONNECT UNION TO CHECK VALVE HOSE

| (a) Slide the clip and disconnect the union to check valve hose from the brake booster assembly. |

|

29. DISCONNECT NO. 2 RADIATOR HOSE

| (a) Slide the clip and disconnect the No. 2 radiator hose from the water inlet. |

|

30. SEPARATE RADIATOR HOSE SUB-ASSEMBLY

| (a) Slide the clip and disconnect the radiator hose sub-assembly from the water outlet. |

|

(b) Remove the 2 bolts and separate the radiator hose sub-assembly from the engine assembly.

31. DISCONNECT INLET HEATER WATER HOSE

| (a) Disengage the clamp. |

|

(b) Slide the clip and disconnect the inlet heater water hose from the water outlet.

32. DISCONNECT OUTLET HEATER WATER HOSE

| (a) Slide the clip and disconnect the outlet heater water hose from the heater water pipe. |

|

33. DISCONNECT NO. 1 FUEL HOSE

| (a) Disengage the 2 claws to remove the No. 2 fuel pipe clamp. |

|

| (b) Remove the No. 1 fuel pipe clamp from the fuel tube connector. |

|

(c) Disconnect the No. 1 fuel hose (for Port Injection).

| (1) Disconnect the No. 1 fuel hose from the fuel pipe. Click here

|

|

(d) Disconnect the No. 1 fuel hose (for Direct Injection).

| (1) Disconnect the No. 1 fuel hose from the fuel pipe. Click here

|

|

| (e) Separate the bolt and disengage the No. 1 fuel hose. |

|

34. DISCONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE SUB-ASSEMBLY

Click here

35. DISCONNECT SUCTION HOSE SUB-ASSEMBLY

Click here

36. DISCONNECT ENGINE WIRE

HINT:

After disconnecting the engine wire, secure it with tape or equivalent to keep it out of the way.

| (a) Remove the No. 2 relay block cover from the engine room relay block and junction block assembly. |

|

| (b) Remove the nut from the engine room relay block and junction block assembly. |

|

(c) Disconnect the 4 connectors from the engine room relay block and junction block assembly.

(d) Disengage the 2 clamps.

(e) Using a screwdriver, disengage the claw and disconnect the engine wire from the engine room relay block and junction block assembly.

| (f) Remove the bolt. |

|

(g) Disengage the 2 clamps and disconnect the engine wire from the vehicle body.

37. DISCONNECT EARTH WIRE

| (a) Remove the 2 bolts and disconnect the earth wire from the vehicle body. |

|

38. SEPARATE STEERING INTERMEDIATE SHAFT ASSEMBLY

Click here

39. REMOVE EXHAUST MANIFOLD

Click here

40. REMOVE FRONT DRIVE SHAFT ASSEMBLY

Click here

41. REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET (for Upper Side)

| (a) Remove the 2 bolts and No. 1 exhaust pipe support bracket from the oil pan sub-assembly. |

|

42. REMOVE FLYWHEEL HOUSING UNDER COVER

| (a) Remove the 2 bolts and flywheel housing under cover. |

|

43. REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

Click here

44. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set an engine lifter.

NOTICE:

| (b) Remove the bolt, 2 nuts and No. 2 engine mounting stay RH. |

|

| (c) Remove the 3 bolts and nut and separate the engine mounting insulator sub-assembly RH from the front No. 1 engine mounting bracket LH. |

|

| (d) Remove the bolt and nut and separate the engine mounting insulator LH from the engine mounting bracket sub-assembly LH. |

|

|

Bolt |

|

Nut |

(e) Remove the 8 bolts and front bumper extension sub-assembly RH and front bumper extension sub-assembly LH from the front frame assembly and vehicle body.

(f) Remove the 4 bolts, 2 nuts and front suspension member bracket sub-assembly RH and front suspension member bracket sub-assembly LH from the front frame assembly and vehicle body.

(g) Operate the engine lifter and remove the engine assembly with transaxle from the vehicle.

NOTICE:

45. DISCONNECT VACUUM HOSE

Click here

46. REMOVE STARTER ASSEMBLY

Click here

47. REMOVE BREATHER PLUG HOSE

Click here

48. DISCONNECT NO. 1 WATER BY-PASS HOSE

Click here

49. DISCONNECT WATER BY-PASS HOSE ASSEMBLY

Click here

50. REMOVE ENGINE WIRE

(a) Disconnect all clamps and connectors and remove the engine wire from the engine assembly with transaxle.

51. INSTALL ENGINE HANGERS

| (a) Install the No. 1 engine hanger and No. 2 engine hanger with the 4 bolts as shown in the illustration. Torque: 33 N·m {337 kgf·cm, 24 ft·lbf}

|

|

(b) Using an engine sling device and engine lifter, secure the engine assembly with transaxle.

NOTICE:

52. REMOVE FRONT FRAME ASSEMBLY

| (a) Remove the bolt and separate the front engine mounting insulator from the front engine mounting bracket. |

|

| (b) Remove the 4 nuts and separate the rear engine mounting insulator from the front frame assembly. |

|

53. REMOVE FRONT ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

| (a) Remove the 3 nuts and front engine mounting insulator from the front frame assembly. |

|

54. REMOVE REAR ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the rear engine mounting insulator is necessary.

Click here

55. REMOVE FRONT ENGINE MOUNTING BRACKET

Click here

56. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

Click here

57. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

Click here

58. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

Click here

59. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

(a) Install the engine assembly to an engine stand.

60. REMOVE ENGINE HANGERS

(a) Remove the 4 bolts, No. 1 engine hanger and No. 2 engine hanger from the cylinder head sub-assembly and cylinder head LH.

61. REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

HINT:

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

| (a) Disengage the clamp. |

|

(b) Remove the bolt, nut and separate the radiator reserve tank assembly.

| (c) Remove the bolt and separate the bracket from the engine mounting insulator sub-assembly RH. |

|

| (d) Disengage the clamp. |

|

(e) Remove the nut, 2 bolts and engine mounting insulator sub-assembly RH from the engine mounting spacer and vehicle body.

62. REMOVE ENGINE MOUNTING SPACER

HINT:

Perform this procedure only when replacement of the engine mounting spacer is necessary.

| (a) Remove the 2 bolts and engine mounting spacer from the vehicle body. |

|

63. REMOVE ENGINE MOUNTING BRACKET SUB-ASSEMBLY LH

HINT:

Perform this procedure only when replacement of the engine mounting bracket sub-assembly LH is necessary.

| (a) Remove the 4 bolts and engine mounting bracket sub-assembly LH from the vehicle body. |

|

64. REMOVE ENGINE MOUNTING INSULATOR LH

HINT:

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

Click here

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > A25a-fxs Engine Control: Camshaft Oil Control Solenoid

Components COMPONENTS ILLUSTRATION *1 CAM TIMING OIL CONTROL SOLENOID ASSEMBLY *2 NO. 1 ENGINE COVER SUB-ASSEMBLY *3 O-RING - - N*m (kgf*cm, ft.*lbf): Specified torque ● Non-reusable part ★ Precoated part - - Inspection INSPECTION PROCEDURE 1. INSPECT CAM TIMING OIL CONTROL SOLENOID ASSEMBLY (a) ...