DESCRIPTION The DC/DC converter varies output voltage based on voltage change signals (VLO signal line) received from the motor generator control ECU. If the vehicle is being driven with an inoperative DC/DC converter, the voltage of the auxiliary battery will drop, which will prevent the continued operation of the vehicle. Therefore, the motor generator control ECU monitors the operation of the DC/DC converter and alerts the driver if it detects a malfunction.

CONFIRMATION DRIVING PATTERN HINT: After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure. Click here

WIRING DIAGRAM Refer to the wiring diagram for the DTC P0A1112. Click here CAUTION / NOTICE / HINT CAUTION:

NOTICE: After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work. Click here PROCEDURE

Click here

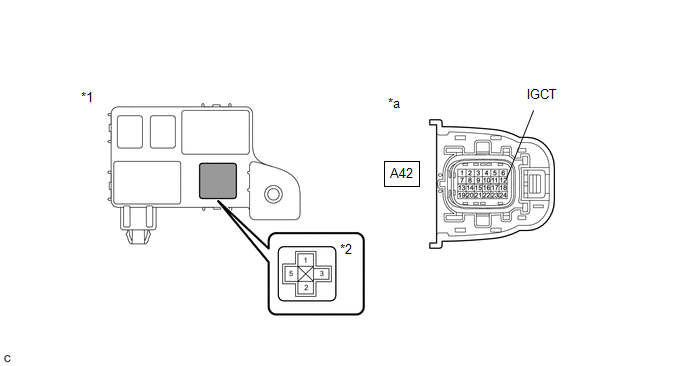

CAUTION: Be sure to wear insulated gloves. (a) Check that the service plug grip is not installed. NOTICE: After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction. (b) Disconnect the A42 inverter with converter assembly connector. (c) Remove the IGCT relay from the instrument panel relay block. (d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

(e) Install the IGCT relay. (f) Reconnect the A42 inverter with converter assembly connector.

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Seat Belt: Child Restraint Seat Anchor Bracket

ComponentsCOMPONENTS ILLUSTRATION *A for Gasoline Model *B for HV Model *1 CHILD RESTRAINT SEAT ANCHOR BRACKET SUB-ASSEMBLY LH *2 CHILD RESTRAINT SEAT ANCHOR BRACKET SUB-ASSEMBLY RH *3 REAR CENTER SEAT OUTER BELT ASSEMBLY *4 REAR SEAT CUSHION ASSEMBLY *5 REAR SEAT CUSHION LOCK HOOK - - Tightening t ...