DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Blind Spot Monitor Sensor Communication Stop Mode |

Any of the following conditions are met:

|

|

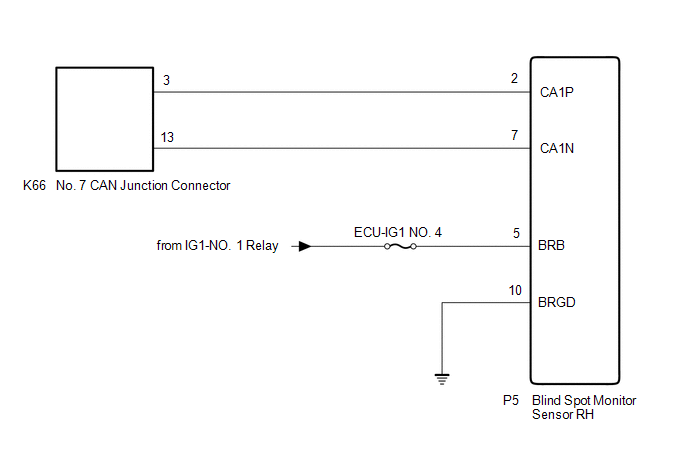

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the engine switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (BLIND SPOT MONITOR SENSOR RH BRANCH LINE) |

(a) Disconnect the cable from the negative (-) battery terminal.

(b) Disconnect the P5 blind spot monitor sensor RH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

P5-5 (BRB) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| OK |  | REPLACE BLIND SPOT MONITOR SENSOR RH |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Center Airbag Sensor Communication Stop Mode |

Any of the following conditions are met:

|

|

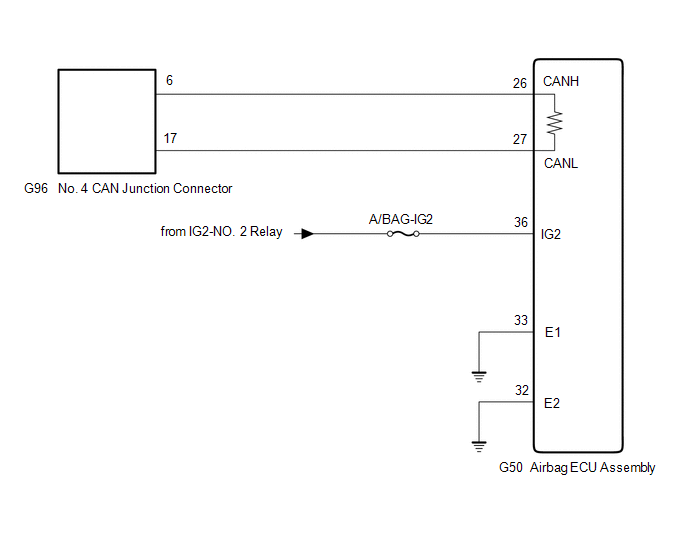

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the engine switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (AIRBAG ECU ASSEMBLY MAIN LINE) |

(a) Disconnect the cable from the negative (-) battery terminal.

(b) Disconnect the G50 airbag ECU assembly connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN MAIN BUS LINES OR CONNECTOR (AIRBAG ECU ASSEMBLY) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G50-36 (IG2) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| OK |  | REPLACE AIRBAG ECU ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Certification ECU Communication Stop Mode |

Any of the following conditions are met:

|

|

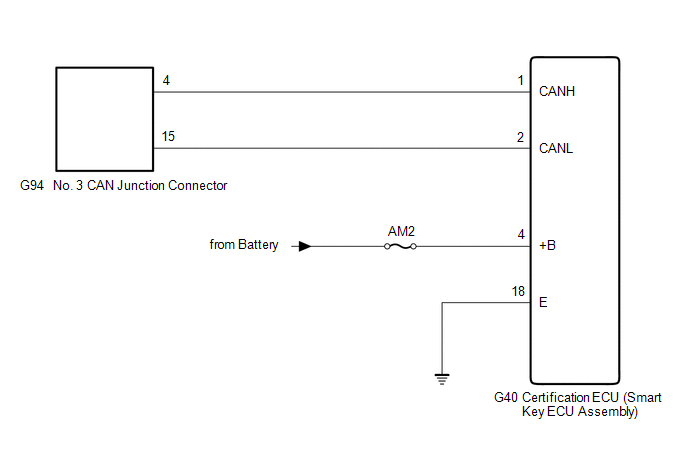

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the engine switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) BRANCH LINE) |

(a) Disconnect the cable from the negative (-) battery terminal.

(b) Disconnect the G40 certification ECU (smart key ECU assembly) connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G40-4 (+B) - Body ground |

Always | 11 to 14 V |

| OK |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Sfi System: Fuel Rail / System Pressure - Too High (P008800). Mass or Volume Air Flow Sensor "A" Circuit Short to Battery (P010012,P010014). Mass or Volume Air Flow Sensor "A" Signal Plausibility Failure (P010064

Fuel Rail / System Pressure - Too High (P008800) DESCRIPTION Refer to DTC P008700. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Memory Note P008800 Fuel Rail / System Pressure - Too High Although the ECM is requesting the fuel pump assembly (for high pressure side) to o ...