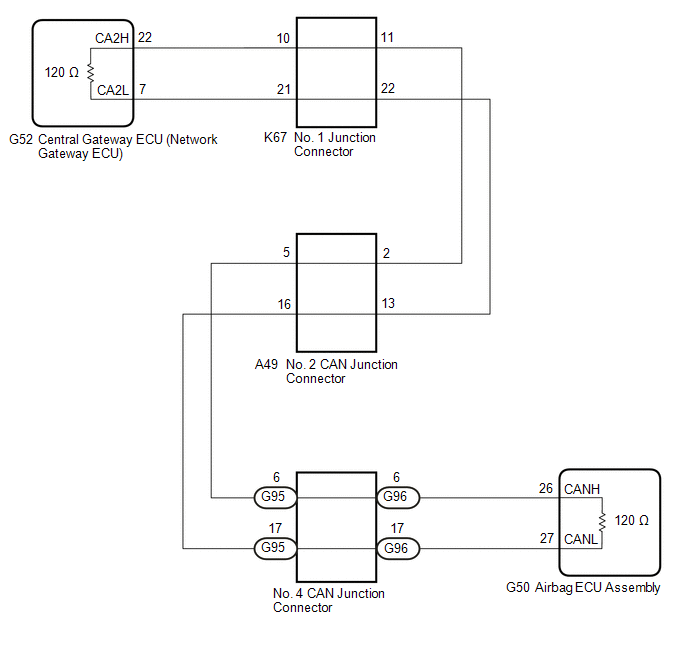

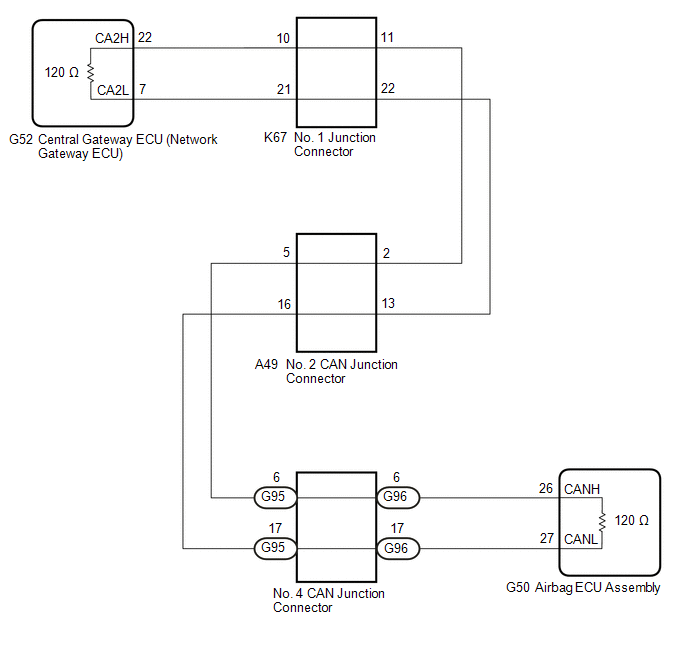

DESCRIPTION There may be an

open circuit in one of the CAN main bus lines when the resistance

between terminals 22 (CA2H) and 7 (CA2L) of the central gateway ECU

(network gateway ECU) is 70 Ω or higher. |

Symptom | Trouble Area | |

Resistance between terminals 22 (CA2H) and 7 (CA2L) of the central gateway ECU (network gateway ECU) is 70 Ω or higher. |

- CAN main bus lines or connector

- Central gateway ECU (network gateway ECU)

- Airbag ECU assembly

- No. 2 CAN junction connector

- No. 4 CAN junction connector

- No. 1 junction connector

| This malfunction is not related to the lines of a CAN branch or to ECUs or sensors connected to a CAN branch. WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION: When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

HINT:

- Before disconnecting related connectors for inspection, push in on each

connector body to check that the connector is not loose or disconnected.

- When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE |

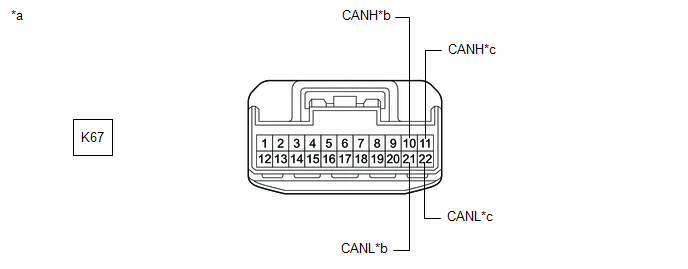

1. | CHECK FOR OPEN IN CAN MAIN BUS LINES (NO. 1 JUNCTION CONNECTOR) |

(a) Disconnect the cable from the negative (-) battery terminal. (b) Disconnect the K67 No. 1 junction connector.

(c) Measure the resistance according to the value(s) in the table below.

|

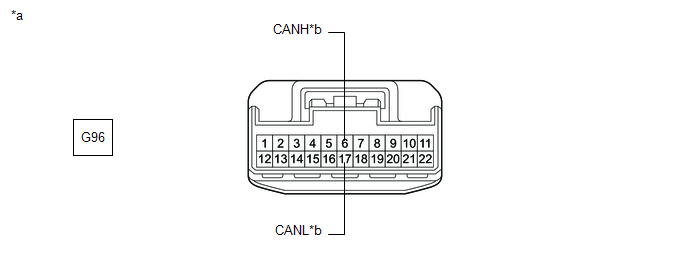

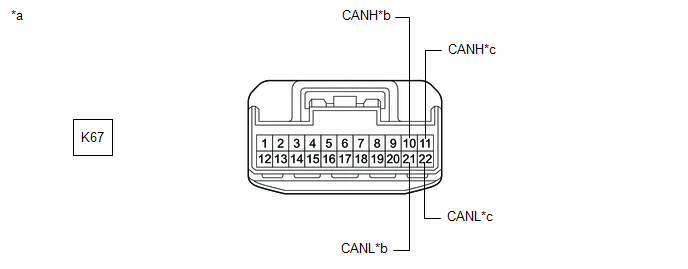

*a | Front view of wire harness connector

(to No. 1 Junction Connector) |

*b | to Central Gateway ECU (Network Gateway ECU) | |

*c | to No. 2 CAN Junction Connector |

- | - |

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | Connected to | |

K67-10 (CANH) - K67-21 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | Central gateway ECU (network gateway ECU) | |

K67-11 (CANH) - K67-22 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | No. 2 CAN junction connector |

|

Result | Proceed to | |

OK | A | |

NG (Line to central gateway ECU (network gateway ECU)) |

B | | NG (Line to No. 2 CAN junction connector) |

C |

| A |

| REPLACE NO. 1 JUNCTION CONNECTOR |

| C |

| GO TO STEP 3 |

|

B |

| |

| 2. |

CHECK FOR OPEN IN CAN MAIN BUS LINES (CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU) - NO. 1 JUNCTION CONNECTOR) |

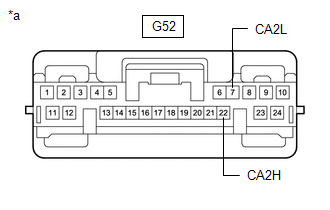

(a) Reconnect the K67 No. 1 junction connector. (b) Disconnect the G52 central gateway ECU (network gateway ECU) connector.

| (c) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

G52-22 (CA2H) - G52-7 (CA2L) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | |

|

|

*a | Front view of wire harness connector

(to Central Gateway ECU (Network Gateway ECU)) | | |

| OK |

| REPLACE CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU) |

| NG |

| REPAIR OR REPLACE CAN MAIN BUS LINES OR CONNECTOR (CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU) - NO. 1 JUNCTION CONNECTOR) |

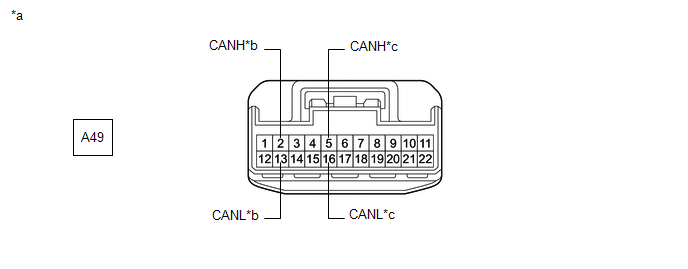

| 3. |

CHECK FOR OPEN IN CAN MAIN BUS LINES (NO. 2 CAN JUNCTION CONNECTOR) |

(a) Reconnect the K67 No. 1 junction connector. (b) Disconnect the A49 No. 2 CAN junction connector.

(c) Measure the resistance according to the value(s) in the table below.

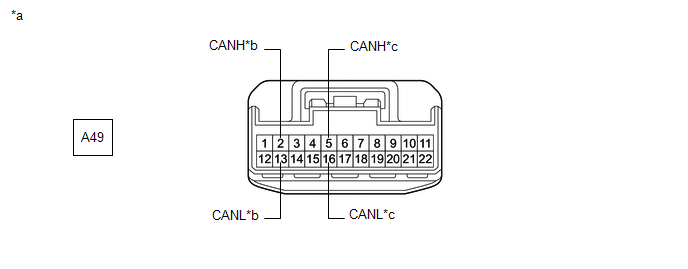

|

*a | Front view of wire harness connector

(to No. 2 CAN Junction Connector) |

*b | to No. 1 Junction Connector | |

*c | to No. 4 CAN Junction Connector |

- | - |

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | Connected to | |

A49-2 (CANH) - A49-13 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | No. 1 junction connector | |

A49-5 (CANH) - A49-16 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | No. 4 CAN junction connector |

|

Result | Proceed to | |

OK | A | |

NG (Line to No. 1 junction connector) |

B | | NG (Line to No. 4 CAN junction connector) |

C |

| A |

| REPLACE NO. 2 CAN JUNCTION CONNECTOR |

| B |

| REPAIR OR REPLACE CAN MAIN BUS LINES OR CONNECTOR (NO. 2 CAN JUNCTION CONNECTOR - NO. 1 JUNCTION CONNECTOR) |

|

C |

| |

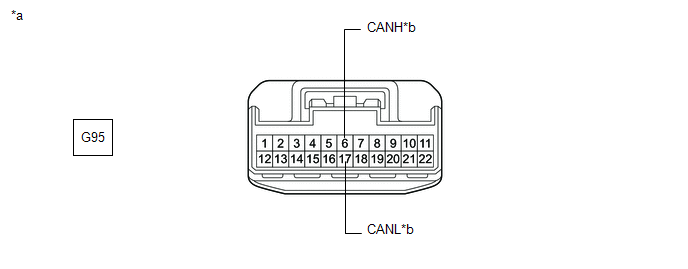

| 4. |

CHECK FOR OPEN IN CAN MAIN BUS LINES (NO. 4 CAN JUNCTION CONNECTOR - NO. 2 CAN JUNCTION CONNECTOR) |

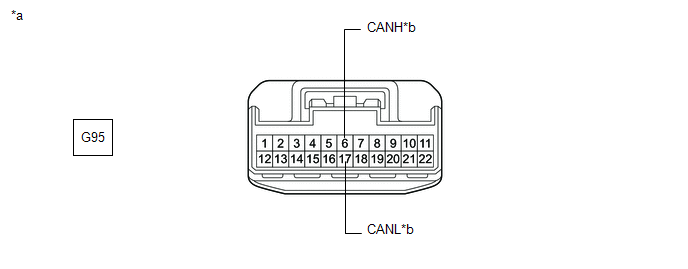

(a) Reconnect the A49 No. 2 CAN junction connector. (b) Disconnect the G95 No. 4 CAN junction connector.

(c) Measure the resistance according to the value(s) in the table below.

|

*a | Front view of wire harness connector

(to No. 4 CAN Junction Connector) |

*b | to No. 2 CAN Junction Connector |

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

G95-6 (CANH) - G95-17 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| NG |

| REPAIR OR REPLACE CAN MAIN BUS LINES OR CONNECTOR (NO. 4 CAN JUNCTION CONNECTOR - NO. 2 CAN JUNCTION CONNECTOR) |

|

OK |

| |

| 5. |

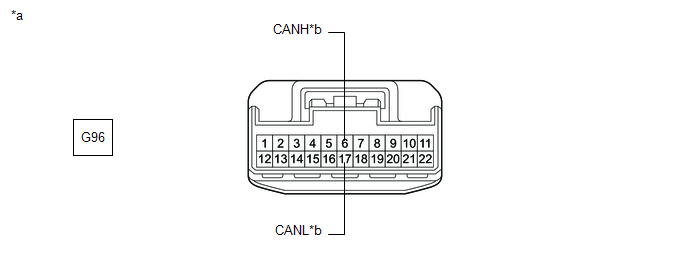

CHECK FOR OPEN IN CAN MAIN BUS LINES (NO. 4 CAN JUNCTION CONNECTOR) |

(a) Reconnect the G95 No. 4 CAN junction connector. (b) Disconnect the G96 No. 4 CAN junction connector.

(c) Measure the resistance according to the value(s) in the table below.

|

*a | Front view of wire harness connector

(to No. 4 CAN Junction Connector) |

*b | to Airbag ECU Assembly |

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

G96-6 (CANH) - G96-17 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

| REPLACE NO. 4 CAN JUNCTION CONNECTOR |

|

NG |

| |

| 6. |

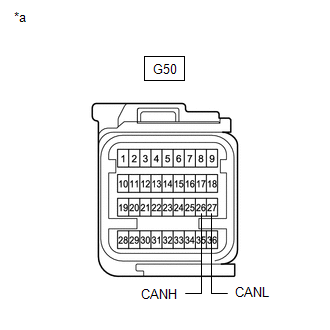

CHECK FOR OPEN IN CAN MAIN BUS LINES (AIRBAG ECU ASSEMBLY - NO. 4 CAN JUNCTION CONNECTOR) |

(a) Reconnect the G96 No. 4 CAN junction connector. (b) Disconnect the G50 airbag ECU assembly connector.

| (c) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

G50-26 (CANH) - G50-27 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω | |

|

|

*a | Front view of wire harness connector

(to Airbag ECU Assembly) | | |

| OK |

| REPLACE AIRBAG ECU ASSEMBLY |

| NG |

| REPAIR OR REPLACE CAN MAIN BUS LINES OR CONNECTOR (AIRBAG ECU ASSEMBLY - NO. 4 CAN JUNCTION CONNECTOR) | |