DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Door Mirror ECU LH Communication Stop Mode |

Any of the following conditions are met:

|

|

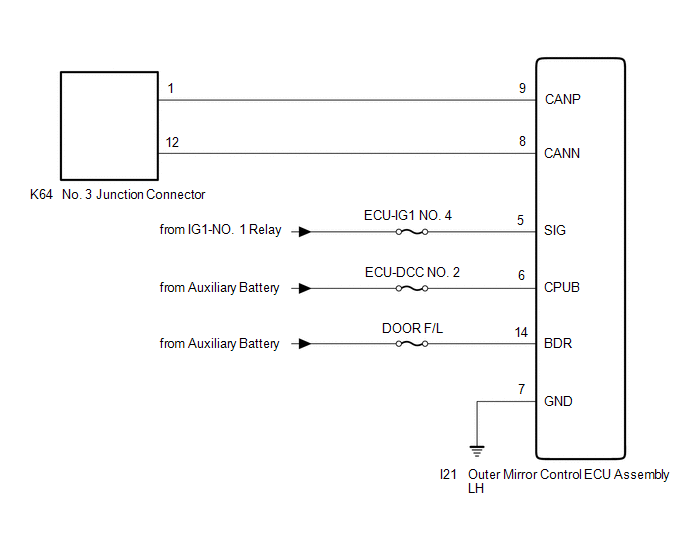

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the power switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (OUTER MIRROR CONTROL ECU ASSEMBLY LH BRANCH LINE) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the I21 outer mirror control ECU assembly LH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (OUTER MIRROR CONTROL ECU ASSEMBLY LH) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) auxiliary battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I21-5 (SIG) - Body ground |

Power switch on (IG) |

11 to 14 V |

|

I21-6 (CPUB) - Body ground |

Power switch off | 11 to 14 V |

|

I21-14 (BDR) - Body ground |

Power switch off | 11 to 14 V |

| OK |  | REPLACE OUTER MIRROR CONTROL ECU ASSEMBLY LH |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Door Mirror ECU RH Communication Stop Mode |

Any of the following conditions are met:

|

|

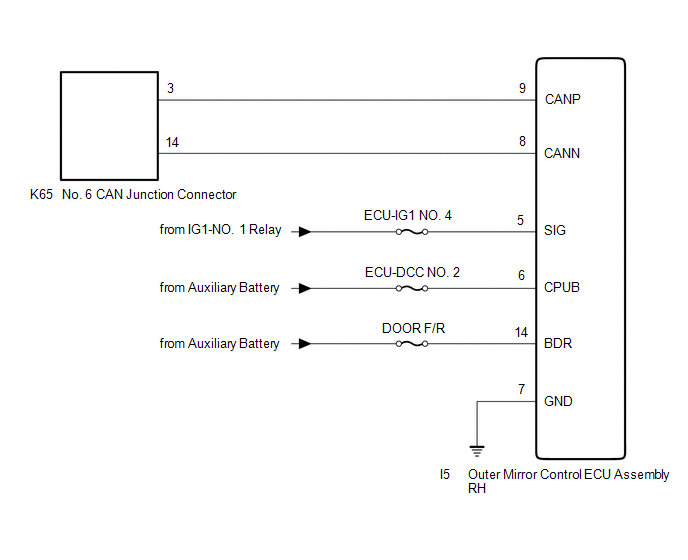

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the power switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (OUTER MIRROR CONTROL ECU ASSEMBLY RH BRANCH LINE) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the I5 outer mirror control ECU assembly RH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (OUTER MIRROR CONTROL ECU ASSEMBLY RH) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

| (a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) auxiliary battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I5-5 (SIG) - Body ground |

Power switch on (IG) |

11 to 14 V |

|

I5-6 (CPUB) - Body ground |

Power switch off | 11 to 14 V |

|

I5-14 (BDR) - Body ground |

Power switch off | 11 to 14 V |

| OK |  | REPLACE OUTER MIRROR CONTROL ECU ASSEMBLY RH |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

DESCRIPTION

|

Detection Item | Symptom |

Trouble Area |

|---|---|---|

| Driver Seat Control ECU Communication Stop Mode |

Any of the following conditions are met:

|

|

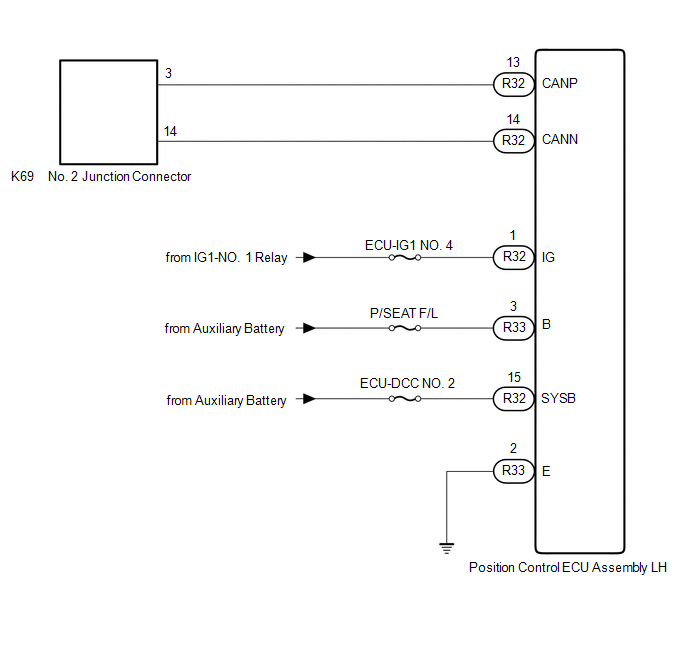

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

Click here

Click here

DTC check procedure: Turn the power switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

Click here

HINT:

PROCEDURE

|

1. | CHECK FOR OPEN IN CAN BUS LINES (POSITION CONTROL ECU ASSEMBLY LH BRANCH LINE) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Disconnect the R32 position control ECU assembly LH connector.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |  | REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (POSITION CONTROL ECU ASSEMBLY LH) |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

(a) Disconnect the R33 position control ECU assembly LH connector.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Reconnect the cable to the negative (-) auxiliary battery terminal.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

R33-3 (B) - Body ground |

Power switch off | 11 to 14 V |

|

R32-1 (IG) - Body ground |

Power switch on (IG) |

11 to 14 V |

|

R32-15 (SYSB) - Body ground |

Power switch off | 11 to 14 V |

| OK |  | REPLACE POSITION CONTROL ECU ASSEMBLY LH |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > 2gr-fks Battery / Charging: Charging System

Charging Failure PROCEDURE 1. CHECK GENERATOR PULLEY WITH CLUTCH (ON-VEHICLE INSPECTION) (a) Start the engine and visually check that the generator rotor assembly (fan) in the generator assembly is operating. OK: The generator rotor assembly (fan) is operating. NG REPLACE GENERATOR PULLEY WITH CLUTC ...