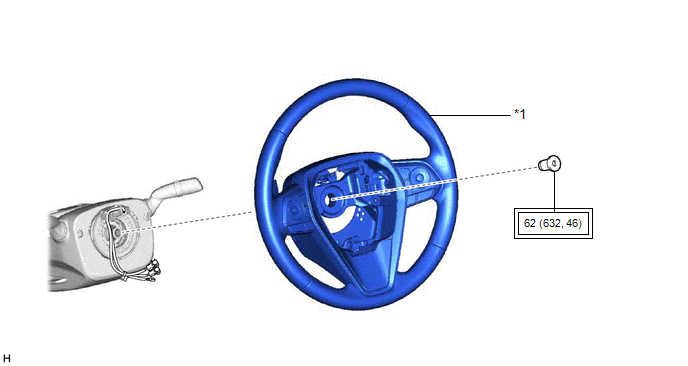

COMPONENTS

ILLUSTRATION

|

*1 | STEERING WHEEL ASSEMBLY |

- | - |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

- | - |

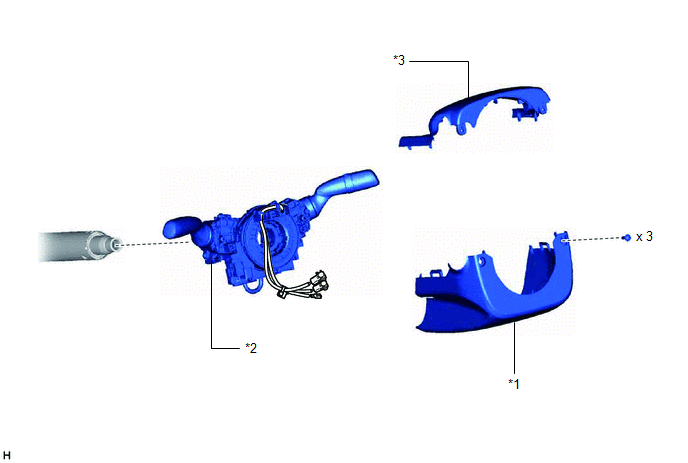

ILLUSTRATION

|

*1 | LOWER STEERING COLUMN COVER |

*2 | TURN SIGNAL SWITCH ASSEMBLY WITH SPIRAL CABLE SUB-ASSEMBLY |

|

*3 | UPPER STEERING COLUMN COVER |

- | - |

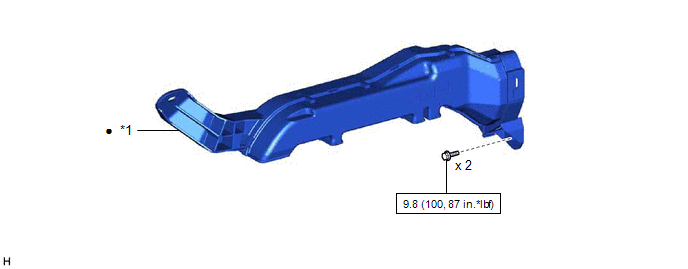

ILLUSTRATION

|

*1 | NO. 1 AIR DUCT |

- | - |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

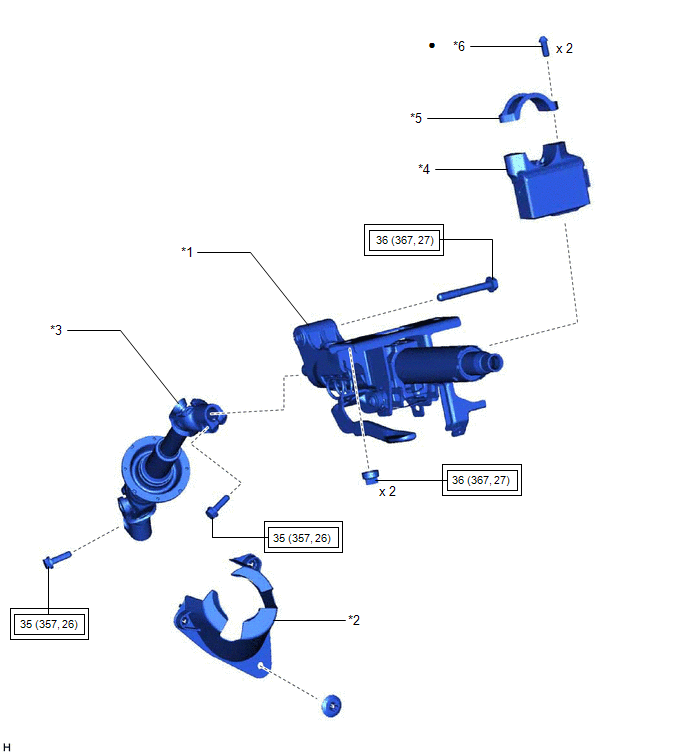

ILLUSTRATION

|

*1 | STEERING COLUMN ASSEMBLY |

*2 | STEERING COLUMN HOLE COVER |

|

*3 | STEERING INTERMEDIATE SHAFT ASSEMBLY |

*4 | STEERING LOCK ACTUATOR ASSEMBLY |

|

*5 | UPPER STEERING COLUMN CLAMP |

*6 | STEERING LOCK SET BOLT |

|

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

DISASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

Before replacing the steering lock actuator assembly, refer to Registration.

for Gasoline Model: Click here

for HV Model: Click here

PROCEDURE

1. REMOVE STEERING LOCK ACTUATOR ASSEMBLY

(a) Secure the steering column assembly in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

| (b) Using SST, strike a punch mark for drilling in the center of the steering lock set bolt. SST: 09622-00010 NOTICE: When striking the punch mark, in order to prevent impact force from being applied to the steering lock actuator assembly, do not use a normal center punch. |

|

(c) Using a drill, drill a hole in the 2 steering lock set bolts and insert a screw extractor.

| (d) Using the screw extractor, remove the 2 steering lock set bolts, upper steering column clamp and steering lock actuator assembly. |

|

INSPECTION

PROCEDURE

1. INSPECT STEERING COLUMN ASSEMBLY

| (a) Check that the 2 bushings are securely installed to the steering column assembly. HINT: If the bushings are deformed, missing or damaged, replace the steering column assembly with a new one. |

|

INSTALLATION

PROCEDURE

1. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

2. INSTALL STEERING COLUMN ASSEMBLY

NOTICE:

Make sure that the wire harness is not interfering with the steering column assembly.

(a) Install the steering column assembly with the bolt and 2 nuts.

Torque:

36 N·m {367 kgf·cm, 27 ft·lbf}

NOTICE:

Tighten the nuts and check the tilt operation again.

(b) Connect each connector and engage each wire harness clamp to the steering column assembly.

3. INSTALL STEERING INTERMEDIATE SHAFT ASSEMBLY

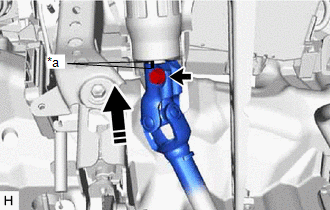

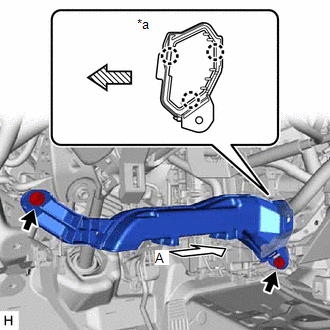

(a) Align the matchmarks on the steering intermediate shaft assembly and steering column assembly.

|

*a | Matchmark |

|

Install in this direction |

(b) Install the steering intermediate shaft assembly to the steering column assembly.

(c) Install the bolt.

Torque:

35 N·m {357 kgf·cm, 26 ft·lbf}

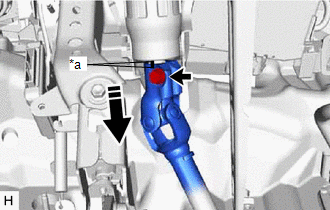

| (d) Tighten the clamp. |

|

4. INSTALL STEERING COLUMN HOLE COVER

| (a) Install the steering column hole cover with the 2 clips. |

|

(b) Install the clip.

(c) Return the floor carpet.

5. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY (for Gasoline Model)

Click here

6. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY (for HV Model)

Click here

7. INSTALL FRONT WHEEL LH

Click here

8. INSTALL NO. 1 AIR DUCT

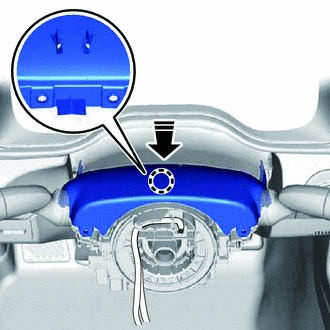

| (a) Engage the 3 claws to install a new No. 1 air duct. |

|

(b) Install the 2 bolts.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

9. INSTALL LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

Click here

10. INSTALL TURN SIGNAL SWITCH ASSEMBLY WITH SPIRAL CABLE SUB-ASSEMBLY

NOTICE:

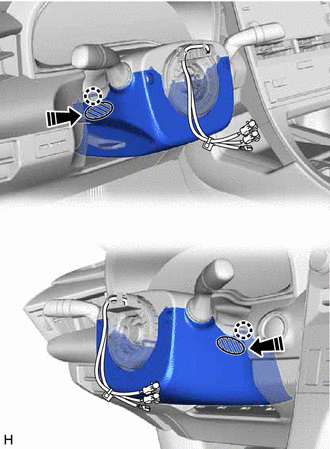

| (a) Using pliers, expand the clamp. |

|

(b) While holding the clamp expanded, install the turn signal switch assembly with spiral cable sub-assembly to the steering column assembly and engage the claw.

(c) Return the clamp to its original position.

(d) Connect the connectors to the turn signal switch assembly with spiral cable sub-assembly.

11. INSTALL UPPER STEERING COLUMN COVER

| (a) Engage the 2 claws and 4 clips to connect the upper steering column cover. |

|

(b) Engage the claw to install the upper steering column cover.

|

Install in this direction |

12. INSTALL LOWER STEERING COLUMN COVER

| (a) Engage the 2 claws to install the lower steering column cover. |

|

| (b) Install the 3 screws. |

|

13. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

14. INSPECT AND ADJUST SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY

Click here

15. INSTALL STEERING WHEEL ASSEMBLY

Click here

16. CHECK STEERING WHEEL CENTER POINT

17. INSTALL HORN BUTTON ASSEMBLY

Click here

18. PERFORM INITIALIZATION AND CALIBRATION (for Gasoline Model)

for Parking Assist Monitor System Initialization: Click here

for Parking Assist Monitor System Calibration: Click here

for Panoramic View Monitor System Initialization: Click here

for Panoramic View Monitor System Calibration: Click here

for Intelligent Clearance Sonar System Calibration: Click here

19. PERFORM INITIALIZATION AND CALIBRATION (for HV Model)

for Parking Assist Monitor System Initialization: Click here

for Parking Assist Monitor System Calibration: Click here

for Panoramic View Monitor System Initialization: Click here

for Panoramic View Monitor System Calibration: Click here

for Intelligent Clearance Sonar System Calibration: Click here

REASSEMBLY

PROCEDURE

1. INSTALL STEERING LOCK ACTUATOR ASSEMBLY

NOTICE:

When replacing the steering lock actuator assembly, perform registration.

(a) Secure the steering column assembly in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

(b) Temporarily install the steering lock actuator assembly and upper steering column clamp with 2 new steering lock set bolts.

| (c) Tighten the 2 steering lock set bolts until the bolt head breaks off. |

|

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during steering column assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced (for Gasoline Model)|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

|

Removal/installation of the turn signal switch assembly with spiral cable sub-assembly |

Steering angle zero point learning (Initialize intelligent clearance sonar system) |

|

|

| Parking Assist Monitor System |

| |

|

Steering angle zero point learning (Initialize panoramic view monitor system) |

Panoramic View Monitor System |

| |

|

Steering lock ECU (steering lock actuator or upper bracket assembly) |

Code registration (Smart Key System (for Start Function)) |

|

|

|

Disconnect cable from negative auxiliary battery terminal |

Perform steering sensor zero point calibration |

Lane Departure Alert System (w/ Steering Control) |

|

|

Pre-collision System | |||

|

Intelligent Clearance Sonar System* | |||

|

Lighting System (for Gasoline Model with Cornering Light) | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic View Monitor System |

| ||

|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*: When performing learning using the Techstream.

Click here | |||

|

Removal/installation of the turn signal switch assembly with spiral cable sub-assembly |

Steering angle zero point learning (Initialize intelligent clearance sonar system) |

|

|

| Parking Assist Monitor System |

| |

|

Steering angle zero point learning (Initialize panoramic view monitor system) |

Panoramic View Monitor System |

| |

|

Steering lock ECU (steering lock actuator or upper bracket assembly) |

Code registration (Smart key System (for Start Function)) |

|

|

|

Disconnect cable from negative auxiliary battery terminal |

Perform steering sensor zero point calibration |

Lane Departure Alert System (w/ Steering Control) |

|

|

Pre-collision System | |||

|

Intelligent Clearance Sonar System* | |||

|

Lighting System (for HV Model with Cornering Light) | |||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

| |

|

Panoramic View Monitor System |

| ||

PROCEDURE

1. PRECAUTION

Click here

2. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

3. REMOVE HORN BUTTON ASSEMBLY

Click here

4. REMOVE STEERING WHEEL ASSEMBLY

Click here

5. REMOVE LOWER STEERING COLUMN COVER

NOTICE:

Removing the lower steering column cover in the incorrect order will cause the parts to break.

(a) Release the tilt and telescopic lever and fully extend and lower the steering column assembly.

(b) Lock the tilt and telescopic lever.

| (c) Remove the 3 screws. |

|

|

Push Area |

|

Push in this direction |

(d) While pressing the push area shown in the illustration to disengage the 2 claws, slightly lower the lower steering column cover.

6. REMOVE UPPER STEERING COLUMN COVER

(a) Disengage the claw and separate the upper steering column cover.

|

Separate in this direction |

| (b) Disengage the 2 claws and 4 clips to remove the upper steering column cover. |

|

7. REMOVE TURN SIGNAL SWITCH ASSEMBLY WITH SPIRAL CABLE SUB-ASSEMBLY

NOTICE:

(a) Disconnect each connector from the turn signal switch assembly with spiral cable sub-assembly.

| (b) Using pliers, expand the clamp. |

|

(c) While holding the clamp expanded, raise the claw using a screwdriver to disengage it, and then remove the turn signal switch assembly with spiral cable sub-assembly from the steering column assembly.

8. REMOVE LOWER NO. 1 INSTRUMENT PANEL AIRBAG ASSEMBLY

Click here

9. REMOVE NO. 1 AIR DUCT

(a) Remove the 2 bolts.

|

*a | View A |

|

Front |

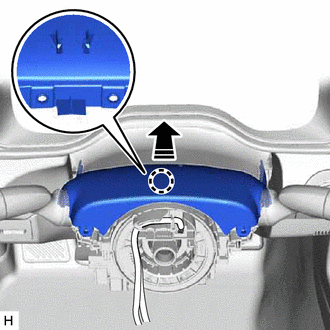

(b) Disengage the 3 claws to remove the No. 1 air duct.

NOTICE:

Be careful not to deform or damage the lower heater case of the air conditioner unit assembly when removing the No. 1 air duct.

10. REMOVE FRONT WHEEL LH

Click here

11. SEPARATE STEERING INTERMEDIATE SHAFT ASSEMBLY (for Gasoline Model)

Click here

12. SEPARATE STEERING INTERMEDIATE SHAFT ASSEMBLY (for HV Model)

Click here

13. REMOVE STEERING COLUMN HOLE COVER

(a) Turn back the floor carpet.

| (b) Remove the clip. |

|

(c) Disengage the 2 clips to remove the steering column hole cover.

14. REMOVE STEERING INTERMEDIATE SHAFT ASSEMBLY

| (a) Using a screwdriver, loosen the clamp as shown in the illustration. |

|

(b) Remove the bolt and slide the steering intermediate shaft assembly.

NOTICE:

Do not remove the steering intermediate shaft assembly from the steering column assembly.

|

*a | Matchmark |

|

Slide in this direction |

(c) Put matchmarks on the steering intermediate shaft assembly and steering column assembly.

(d) Remove the steering intermediate shaft assembly from the steering column assembly.

15. REMOVE STEERING COLUMN ASSEMBLY

(a) Disconnect each connector and disengage each wire harness clamp from the steering column assembly.

| (b) Remove the bolt, 2 nuts and steering column assembly. |

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Sfi System: Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B (P001700)

DESCRIPTION Refer to DTC P001313. Click here DTC No. Detection Item DTC Detection Condition Trouble Area MIL Memory Note P001700 Crankshaft Position - Camshaft Position Correlation Bank 1 Sensor B Deviation in the crankshaft position sensor signal and camshaft position sensor (for exhaust camshaft) ...