DESCRIPTION

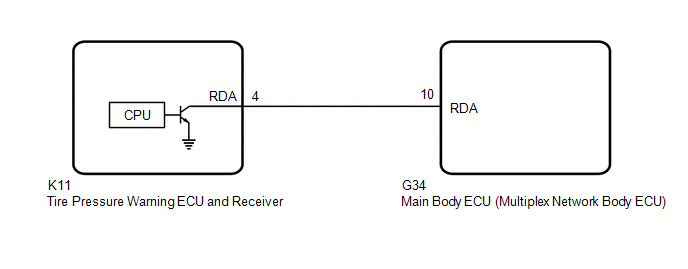

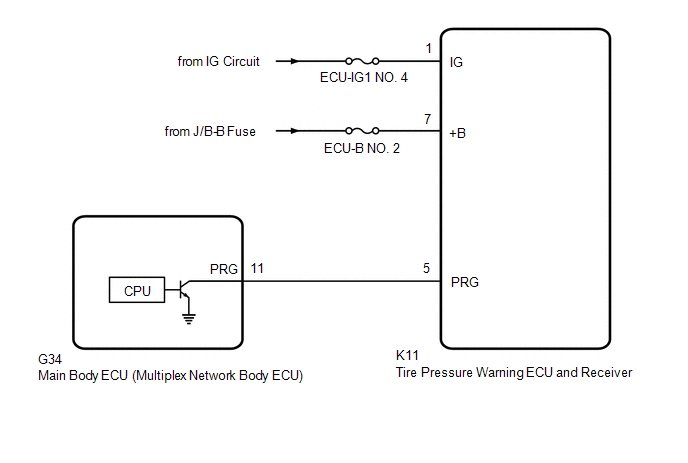

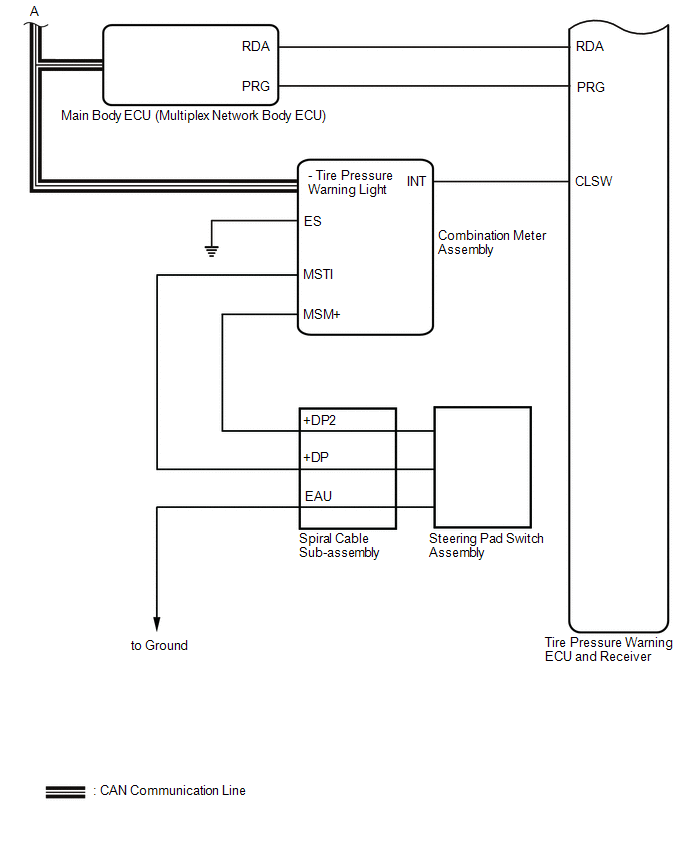

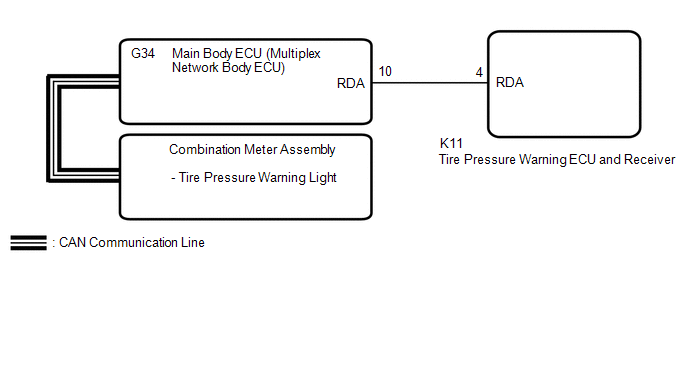

The main body ECU (multiplex network body ECU) and tire pressure warning ECU and receiver communicate by direct line. If a malfunction occurs in this communication signal, B1247 is output by the main body ECU (multiplex network body ECU).

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B1247 |

Tire Pressure Monitor Receiver Communication Stop |

Communication between the tire pressure warning ECU and receiver and main body ECU (multiplex network body ECU) is interrupted for 10 seconds or more. |

| This DTC is for main body ECU (multiplex network body ECU) |

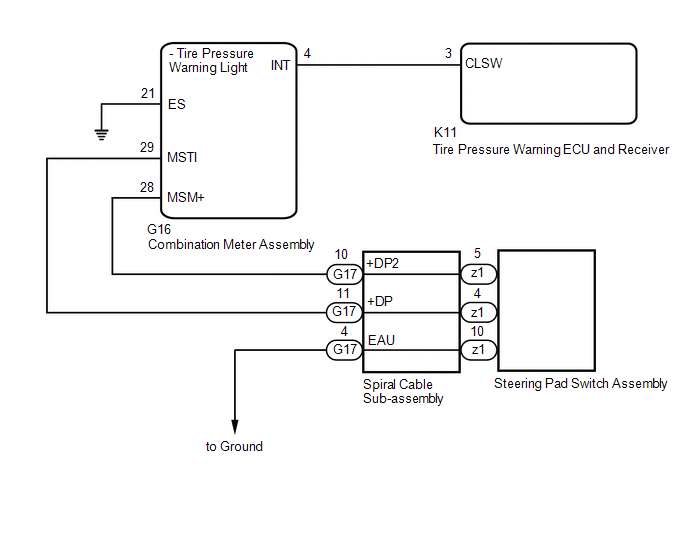

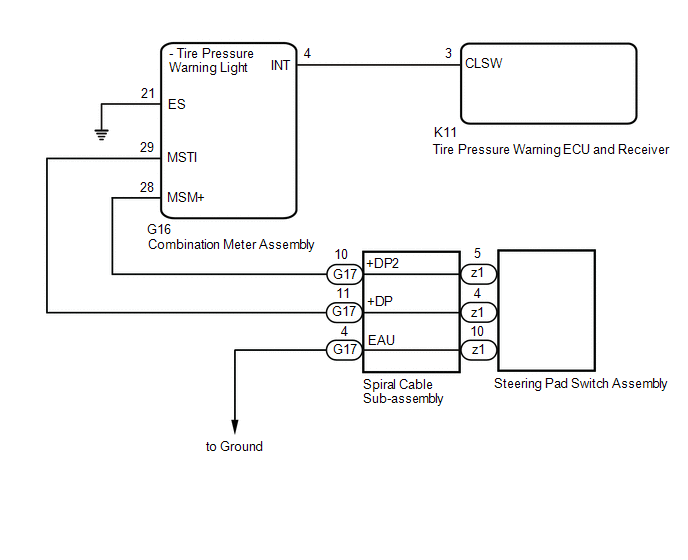

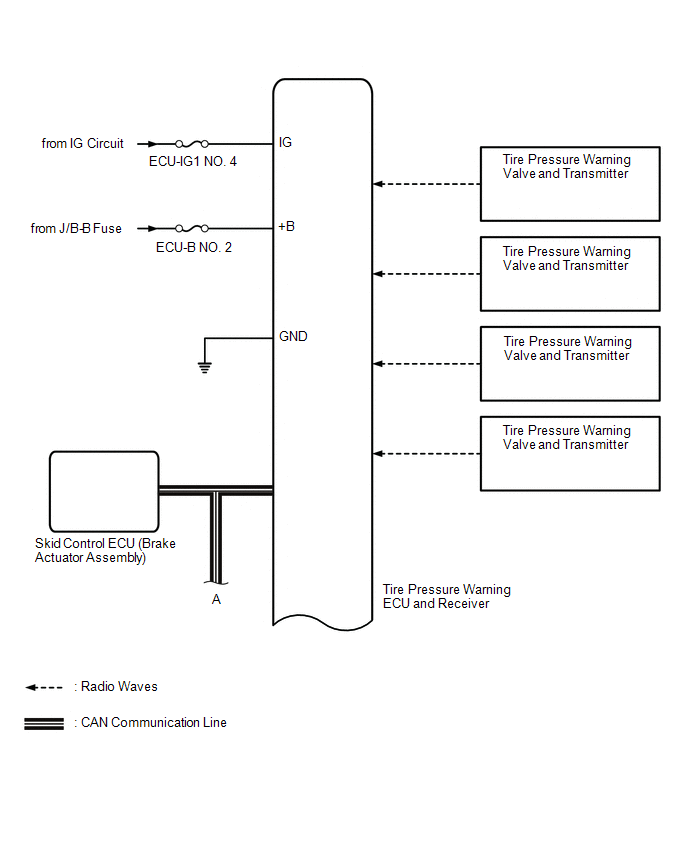

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver after the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver after the ECU has been replaced.

Click here

PROCEDURE

|

1. | INSPECT TIRE PRESSURE WARNING ECU AND RECEIVER (OUTPUT WAVEFORM) |

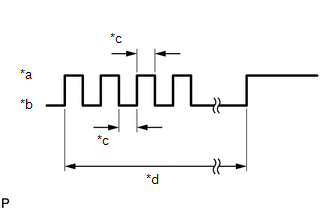

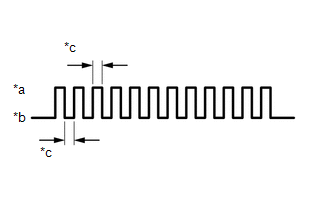

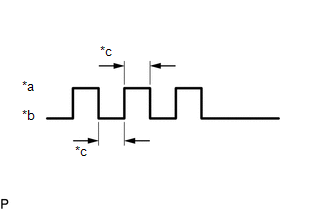

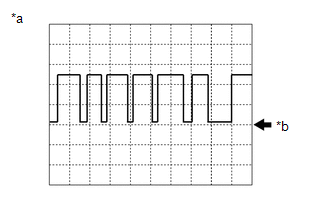

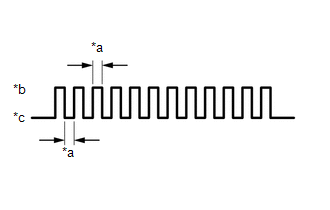

| (a) Using an oscilloscope, check the waveform. NOTICE: With the connector connected, check from the backside of the connector. Standard Voltage:

|

|

|

Result | Proceed to |

|---|---|

|

Waveform is as shown in the illustration. (Waveform alternates between 10.5 V or higher and 0.5 V or less) |

A |

| Waveform does not change from 10.5 V or higher |

B |

| Waveform does not change from 0.5 V or less |

C |

| A |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| B |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 2. |

CHECK TERMINAL VOLTAGE (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) OUTPUT) |

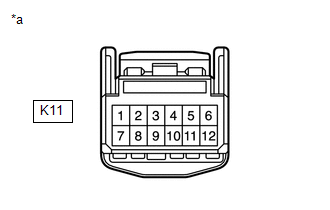

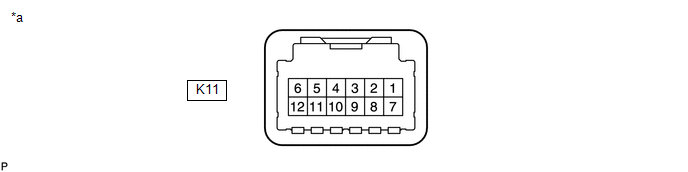

(a) Disconnect the K11 tire pressure warning ECU and receiver connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-4 (RDA) - Body ground |

Engine switch on (IG) |

10.5 V or higher |

| OK |  | REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 3. |

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) - TIRE PRESSURE WARNING ECU AND RECEIVER) |

(a) Turn the engine switch off.

(b) Disconnect the G34 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G34-10 (RDA) - K11-4 (RDA) |

Always | Below 1 Ω |

|

G34-10 (RDA) or K11-4 (RDA) - Body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

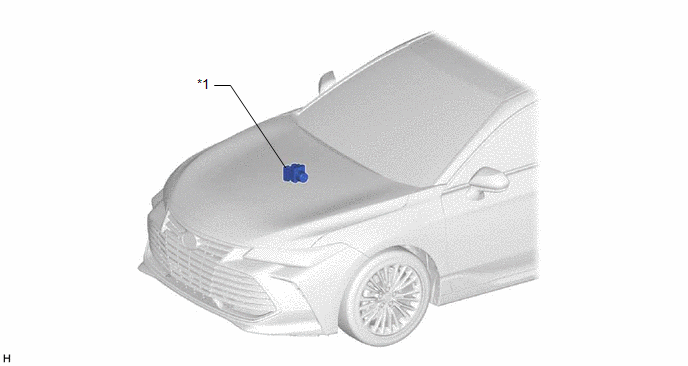

DESCRIPTION

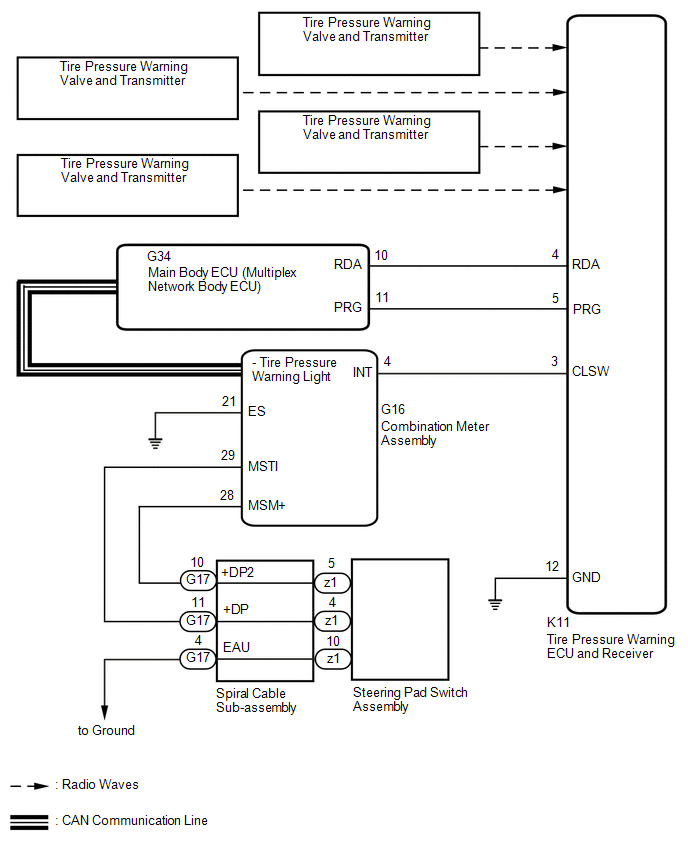

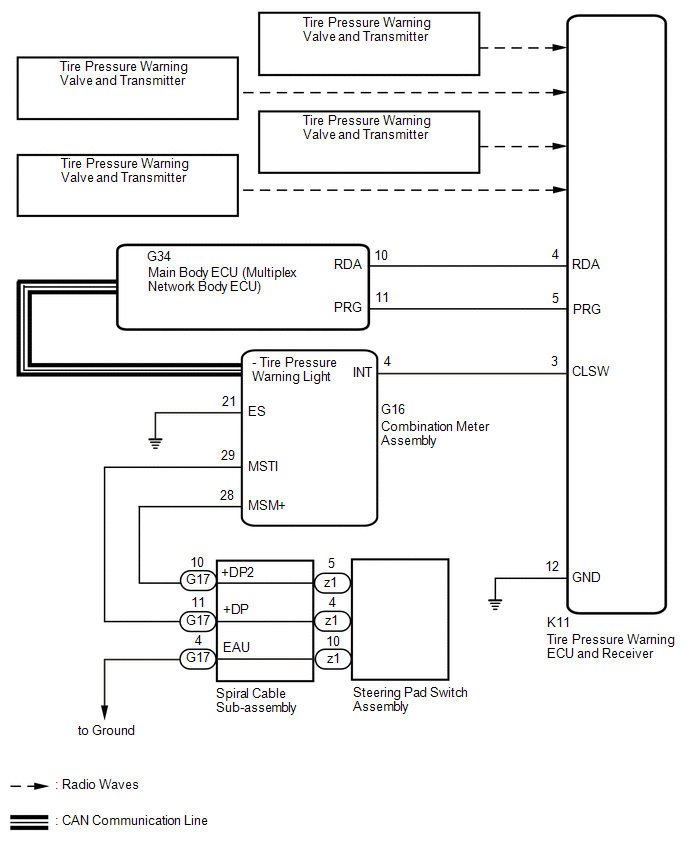

The tire pressure warning valve and transmitters that are installed in the tire and wheel assemblies measure the tire pressure of each wheel. The measured values are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter assembly illuminates. The tire pressure warning ECU and receiver stores a DTC when the tire pressure warning valve and transmitter stops transmitting signals. The signals can be forcibly transmitted by releasing the tire pressure rapidly. The stored DTCs are cleared when signal transmission resumes.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2111 |

Transmitter ID1 Operation Stop |

Tire pressure warning valve and transmitters stop transmitting signals |

| - |

|

C2112 | Transmitter ID2 Operation Stop |

Tire pressure warning valve and transmitters stop transmitting signals |

| - |

|

C2113 | Transmitter ID3 Operation Stop |

Tire pressure warning valve and transmitters stop transmitting signals |

| - |

|

C2114 | Transmitter ID4 Operation Stop |

Tire pressure warning valve and transmitters stop transmitting signals |

| - |

HINT:

It is necessary to perform the following procedure to identify the tire pressure warning valve and transmitter that is malfunctioning because it cannot be identified by the output DTC.

WIRING DIAGRAM

PROCEDURE

| 1. |

PERFORM FORCED TRANSMISSION OF TRANSMITTER ID OF ALL WHEELS |

(a) Set the tire pressure to the specified value.

Click here

(b) Turn the engine switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the engine switch on (IG).

(e) Turn the Techstream on.

(f) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(g) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

HINT:

*1: It may take a few minutes until the values are displayed. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121 to C2124.

Click here

|

Tester Display |

|---|

| ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

(h) Rapidly reduce the tire pressure for each wheel at least 40 kPa (0.4 kgf/cm2, 5.8 psi) within 30 seconds.

(1) Check that each "ID Tire Inflation Pressure" value displayed on the Techstream has changed.

OK:

Each "ID Tire Inflation Pressure" value displayed on the Techstream changed to the actual tire inflation pressure value.

NOTICE:

(2) After confirming that all of the tire "ID Tire Inflation Pressure" values displayed on the Techstream have changed, set the tire pressure to the appropriate specified values.

HINT:

If an "ID Tire Inflation Pressure" value displayed on the Techstream has not changed after rechecking, inspect for another problem.

Click here

| OK |  |

END |

| NG |  | GO TO TRANSMITTER AND RECEIVER INSPECTION PROCEDURE |

DESCRIPTION

The tire pressure warning valve and transmitters that are installed in the tire and wheel assemblies measure the tire pressure of each wheel. The measured values are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter assembly illuminates.

The tire pressure warning valve and transmitters constantly send radio waves to the tire pressure warning ECU and receiver.

Under the conditions below, the tire pressure warning ECU and receiver is unable to receive the signals from the tire pressure warning valve and transmitters, and a DTC is stored.

HINT:

When no transmitter ID is received from a tire pressure warning valve and transmitter for 20 minutes or more while the vehicle speed is more than 40 km/h (25 mph), or no transmitter ID is received from all of the tire pressure warning valve and transmitters for 20 minutes or more, DTCs from C2121 to C2124 are stored.

DTCs C2121 to C2124 can only be cleared by using the Techstream. DTCs C2181 to C2184 can be cleared when the tire pressure warning valve and transmitter sends a forced transmission signal or test mode ends. DTCs C2181 to C2184 are output only in test mode.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2121 |

Transmitter ID 1 not Received (Main) |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

| - |

|

C2122 | Transmitter ID 2 not Received (Main) |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

| - |

|

C2123 | Transmitter ID 3 not Received (Main) |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

| - |

|

C2124 | Transmitter ID 4 not Received (Main) |

Either of the following conditions (a) or (b) is met: (a) When all conditions below are met:

(b) When both conditions below are met:

|

| - |

|

C2181 | Transmitter ID 1 not Received (for Test Diagnosis) |

Test mode procedure is performed. |

| - |

|

C2182 | Transmitter ID 2 not Received (for Test Diagnosis) |

Test mode procedure is performed. |

| - |

|

C2183 | Transmitter ID 3 not Received (for Test Diagnosis) |

Test mode procedure is performed. |

| - |

|

C2184 | Transmitter ID 4 not Received (for Test Diagnosis) |

Test mode procedure is performed. |

| - |

NOTICE:

HINT:

It is necessary to perform the following procedure to identify the tire pressure warning valve and transmitter that is malfunctioning because it cannot be identified by the output DTC.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

PROCEDURE

|

1. | CHECK FREQUENCY RECEIVING CONDITION |

(a) Check that the following conditions are not met:

(1) Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

HINT:

If the vehicle is located in an area such as the one described above, the tire pressure warning light may illuminate after blinking for 1 minute due to interfering radio frequencies.

(2) Devices using similar radio frequencies are used in the vehicle.

HINT:

Radio transmissions may be interrupted due to the surroundings or devices installed by the user.

|

Result | Proceed to |

|---|---|

|

There is no device or facility that uses electrical waves of approximately the same frequency in the vicinity of the vehicle or inside the vehicle. |

A |

| There is a device or facility that uses electrical waves of approximately the same frequency in the vicinity of the vehicle or inside the vehicle. |

B |

| B |

| GO TO STEP 10 |

|

| 2. |

CONFIRM OUTPUT DTC |

(a) Check the stored DTC.

|

Result | Proceed to |

|---|---|

|

Any DTCs from C2121 to C2124 are output (C2181 to C2184 when in Test Mode) |

A |

| All DTCs from C2121 to C2124 are output (C2181 to C2184 when in Test Mode) |

B |

| B |

| GO TO STEP 5 |

|

| 3. |

IDENTIFY TRANSMITTER CORRESPONDING TO DTC (TIRE POSITION) |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Display the "ID Tire Position" value for each wheel using the Techstream.

(g) Refer to the following chart and check the wheel position of the DTC and transmitter match.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Position | ID1 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 2 Tire Position | ID2 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID2 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 3 Tire Position | ID3 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID3 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 4 Tire Position | ID4 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID4 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

HINT:

Refer to the following chart for the Data List items that correspond to the DTCs.

|

DTC No. | Detection Item |

Data List |

|---|---|---|

| C2121 |

Transmitter ID 1 not Received (Main) |

ID1 Tire Position |

|

C2181 | Transmitter ID 1 not Received (for Test Diagnosis) | |

|

C2122 | Transmitter ID 2 not Received (Main) |

ID2 Tire Position |

|

C2182 | Transmitter ID 2 not Received (for Test Diagnosis) | |

|

C2123 | Transmitter ID 3 not Received (Main) |

ID3 Tire Position |

|

C2183 | Transmitter ID 3 not Received (for Test Diagnosis) | |

|

C2124 | Transmitter ID 4 not Received (Main) |

ID4 Tire Position |

|

C2184 | Transmitter ID 4 not Received (for Test Diagnosis) |

|

Tester Display |

|---|

| ID 1 Tire Position |

|

ID 2 Tire Position |

|

ID 3 Tire Position |

|

ID 4 Tire Position |

|

| 4. |

CHECK TRANSMITTER ID |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Refer to the following chart and record the tire pressure warning valve and transmitter ID of the output DTC.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

HINT:

|

DTC No. |

Detection Item |

Data List |

|---|---|---|

|

C2121 |

Transmitter ID 1 not Received (Main) |

Registered ID 1 code |

|

C2181 |

Transmitter ID 1 not Received (for Test Diagnosis) |

|

|

C2122 |

Transmitter ID 2 not Received (Main) |

Registered ID 2 code |

|

C2182 |

Transmitter ID 2 not Received (for Test Diagnosis) |

|

|

C2123 |

Transmitter ID 3 not Received (Main) |

Registered ID 3 code |

|

C2183 |

Transmitter ID 3 not Received (for Test Diagnosis) |

|

|

C2124 |

Transmitter ID 4 not Received (Main) |

Registered ID 4 code |

|

C2184 |

Transmitter ID 4 not Received (for Test Diagnosis) |

|

Tester Display |

|---|

| Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

(g) Disassemble the tire indicated in the output DTC and check the tire pressure warning valve and transmitter ID.

|

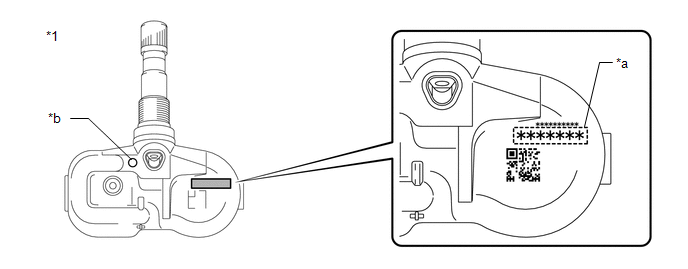

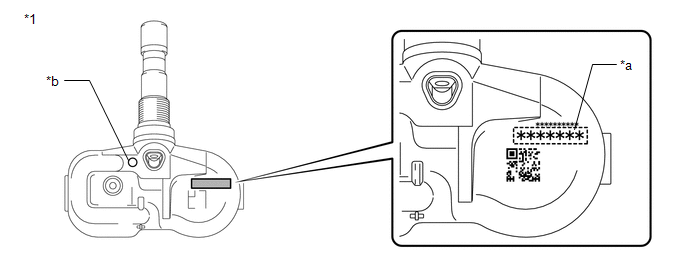

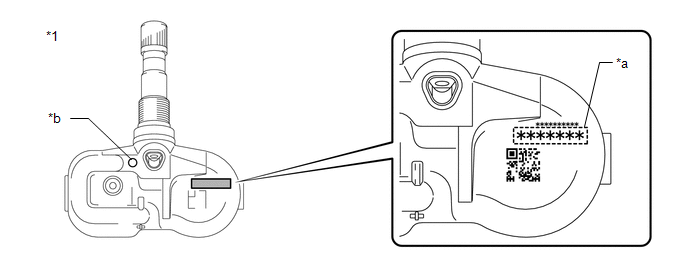

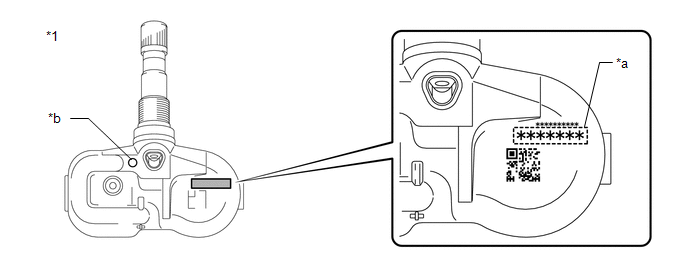

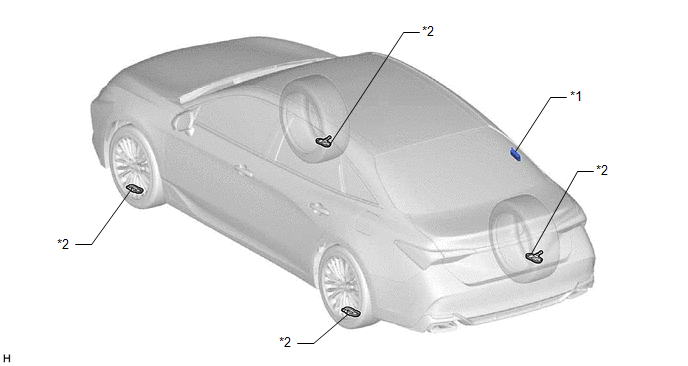

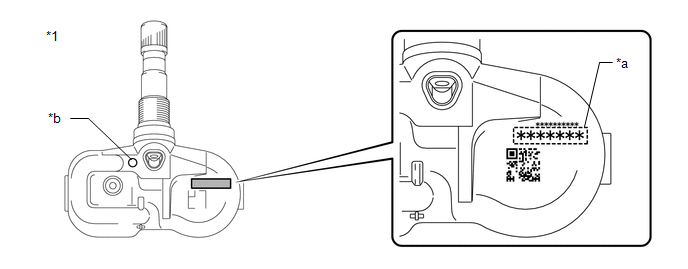

*1 | Tire Pressure Warning Valve and Transmitter |

- | - |

|

*a | Transmitter ID (7-digit Number) |

*b | Wheel Speed Type Tire Inflation Pressure Display Function Identification Mark |

NOTICE:

For vehicles equipped with the wheel speed type tire inflation pressure display function, be sure to use tire pressure warning valve and transmitters with identification marks.

(h) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result | Proceed to |

|---|---|

|

Match | A |

|

Do not match | B |

| A |

| REPLACE TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

| B |

| GO TO STEP 7 |

| 5. |

TEST MODE INSPECTION (C2181 to C2184) |

(a) Perform a test mode inspection and perform Transmitter Data Reception Check (C2181 to C2184).

Click here

| OK |  | END |

|

| 6. |

CHECK TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Refer to the following chart and record all of the tire pressure warning valve and transmitter IDs.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

HINT:

|

Tester Display |

|---|

| Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

(g) Disassemble all of the tires and check the tire pressure warning valve and transmitter IDs.

|

*1 | Tire Pressure Warning Valve and Transmitter |

- | - |

|

*a | Transmitter ID (7-digit Number) |

*b | Wheel Speed Type Tire Inflation Pressure Display Function Identification Mark |

NOTICE:

For vehicles equipped with the wheel speed type tire inflation pressure display function, be sure to use tire pressure warning valve and transmitters with identification marks.

(h) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result | Proceed to |

|---|---|

|

Match | A |

|

Do not match | B |

| A |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 7. |

REGISTRATION OF TRANSMITTER ID |

(a) Perform registration.

Click here

|

| 8. |

PERFORM INITIALIZATION |

(a) Perform initialization.

Click here

|

| 9. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Tire Pressure Monitor > Clear DTCs| NEXT |  | END |

| 10. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Tire Pressure Monitor > Clear DTCs| NEXT |  | END |

DESCRIPTION

If ID registration via the automatic ID registration function is canceled or the tire pressure warning ECU and receiver does not receive data from the tire pressure warning valve and transmitters after the tire pressure warning valve and transmitter ID registration is completed using the Techstream, the tire pressure warning ECU and receiver stores DTC C2126.

After ID registration is complete using the Techstream, the tire pressure warning light illuminates after blinking for 1 minute. When the tire pressure warning ECU and receiver receives the data from all tire pressure warning valve and transmitters with registered IDs, the tire pressure is judged to be normal and the tire pressure warning light turns off.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2126 |

Transmitter ID not Received (Main) |

|

| - |

NOTICE:

If DTC C2126 is stored, C2128 may also be stored. If DTC C2128 is stored, perform troubleshooting for DTC C2128 before performing troubleshooting for DTC C2126.

HINT:

The purpose of this DTC is to help prevent delivering a vehicle that has incorrectly registered transmitter IDs. After all IDs are registered, DTC C2126 is detected and the tire pressure warning light blinks for 1 minute and then illuminates. If the tire pressure warning light does not go off after a little while, the transmitter IDs may be incorrectly registered.

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

PROCEDURE

|

1. | IDENTIFY TRANSMITTER NOT RECEIVED |

(a) Set the tire pressure to the specified value.

Click here

(b) Turn the engine switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the engine switch on (IG).

(e) Turn the Techstream on.

(f) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(g) Display the "ID Tire Inflation Pressure" value for each wheel using the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge)/ 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

HINT:

|

Tester Display |

|---|

| ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

(h) Rapidly reduce the tire pressure for each wheel at least 40 kPa (0.4 kg/cm2, 5.8 psi) within 30 seconds. If the "ID Tire Inflation Pressure" value displayed on the Techstream does not change, the tire pressure warning valve and transmitter corresponding to the unchanged "ID Tire Inflation Pressure" value was the cause of the output DTC.

HINT:

(i) Check the Data List.

NOTICE:

(j) After confirming that the "ID Tire Inflation Pressure" value for one tire has changed, repeat this procedure one by one. Identify the transmitter not received.

|

Result | Proceed to |

|---|---|

|

Change in all tire inflation pressure data |

A |

| No change in all tire inflation pressure data |

B |

| No change in any tire inflation pressure data |

C |

| A |

| END |

| C |

| GO TO STEP 3 |

|

| 2. |

CHECK TRANSMITTER ID |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

HINT:

|

Tester Display |

|---|

| Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

(g) Disassemble all of the tires and check the tire pressure warning valve and transmitter IDs.

|

*1 | Tire Pressure Warning Valve and Transmitter |

- | - |

|

*a | Transmitter ID (7-digit Number) |

*b | Wheel Speed Type Tire Inflation Pressure Display Function Identification Mark |

NOTICE:

For vehicles equipped with the wheel speed type tire inflation pressure display function, be sure to use tire pressure warning valve and transmitters with identification marks.

(h) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result | Proceed to |

|---|---|

|

Match | A |

|

Do not match | B |

| A |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| B |

| GO TO STEP 4 |

| 3. |

CHECK TRANSMITTER ID |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

HINT:

|

Tester Display |

|---|

| Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

(g) Disassemble all of the tires and check the tire pressure warning valve and transmitter IDs.

|

*1 | Tire Pressure Warning Valve and Transmitter |

- | - |

|

*a | Transmitter ID (7-digit Number) |

*b | Wheel Speed Type Tire Inflation Pressure Display Function Identification Mark |

NOTICE:

For vehicles equipped with the wheel speed type tire inflation pressure display function, be sure to use tire pressure warning valve and transmitters with identification marks.

(h) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result | Proceed to |

|---|---|

|

Match | A |

|

Do not match | B |

| A |

| REPLACE TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

|

| 4. |

REGISTRATION OF TRANSMITTER ID |

(a) Perform registration.

Click here

|

| 5. |

PERFORM INITIALIZATION |

(a) Perform initialization.

Click here

| NEXT |  | END |

DESCRIPTION

When ID registration is being performed via the automatic ID registration function, the tire pressure warning ECU and receiver stores C2128 and the tire pressure warning light flashes for 1 minute and then illuminates.

When the tire pressure warning ECU receives data from all registered tire pressure warning valve and transmitters and the system is judged to be normal, the tire pressure warning light turns off.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2128 |

Auto ID Under Registration |

ID registration is being performed via the automatic ID registration function |

Electronically controlled brake system |

- |

PROCEDURE

| 1. |

CHECK FOR DTC (ELECTRONICALLY CONTROLLED BRAKE SYSTEM) |

(a) Turn the engine switch on (IG).

(b) Check if the electronically controlled brake system DTCs are output.

Chassis > ABS/VSC/TRAC/EPB > Trouble CodesHINT:

If DTC C2128 is stored, electronically controlled brake system DTCs may also be stored. If electronically controlled brake system DTCs are stored, perform troubleshooting for the electronically controlled brake system before performing ID registration via the automatic ID registration function.

|

Result | Proceed to |

|---|---|

|

DTCs are not output | A |

|

DTCs are output | B |

| B |

| GO TO ELECTRONICALLY CONTROLLED BRAKE SYSTEM |

|

| 2. |

REGISTRATION OF TRANSMITTER ID (ID REGISTRATION VIA AUTOMATIC ID REGISTRATION FUNCTION) |

(a) Turn the engine switch off.

(b) Turn the engine switch on (IG).

(c) Perform ID registration for the tire pressure warning ECU and receiver (ID registration via the automatic ID registration function).

Click here

HINT:

Perform the following procedures within 1 trip and do not turn the engine switch off.

|

| 3. |

READ VALUE USING TECHSTREAM ([RAM] AUTO ID REGISTERED WHEEL JUDGMENT STATUS) |

(a) Connect the Techstream to the DLC3.

(b) Turn the Techstream on.

(c) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(d) According to the display on the Techstream, display the ECU Data List.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

|---|

| [RAM] Auto ID Registered FL Wheel Judgment Status |

|

[RAM] Auto ID Registered FR Wheel Judgment Status |

|

[RAM] Auto ID Registered RL Wheel Judgment Status |

|

[RAM] Auto ID Registered RR Wheel Judgment Status |

(e) Refer to the following chart and check the "[RAM] Auto ID Registered Wheel Judgment Status" of each transmitter.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

[RAM] Auto ID Registered FL Wheel Judgment Status |

FL wheel registration status during automatic ID registration (RAM) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Cleared each time the engine switch is turned on (IG) from off. |

|

[RAM] Auto ID Registered FR Wheel Judgment Status |

FR wheel registration status during automatic ID registration (RAM) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Cleared each time the engine switch is turned on (IG) from off. |

|

[RAM] Auto ID Registered RL Wheel Judgment Status |

RL wheel registration status during automatic ID registration (RAM) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Cleared each time the engine switch is turned on (IG) from off. |

|

[RAM] Auto ID Registered RR Wheel Judgment Status |

RR wheel registration status during automatic ID registration (RAM) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Cleared each time the engine switch is turned on (IG) from off. |

| Result |

Proceed to |

|---|---|

| "Under a Judgment of Side by Side Car Influence or Under a Judgment" is displayed for 1 or more "[RAM] Auto ID Registered Wheel Judgment Status" Data List items. | A |

|

"Under a Judgment of Side by Side Car Influence or Under a Judgment" is not displayed for any "[RAM] Auto ID Registered Wheel Judgment Status" Data List items. | B |

| B |

| GO TO STEP 5 |

|

| 4. |

REGISTRATION OF TRANSMITTER ID (ID REGISTRATION VIA TECHSTREAM) |

(a) Perform ID registration for the tire pressure warning ECU and receiver (ID registration via Techstream).

Click here

| NEXT |  | END |

| 5. |

REGISTRATION OF TRANSMITTER ID (ID REGISTRATION VIA TECHSTREAM) |

(a) Perform ID registration for the tire pressure warning ECU and receiver (ID registration via Techstream).

Click here

| NEXT |  | END |

DESCRIPTION

The tire pressure warning valve and transmitters that are installed in the tire and wheel assemblies measure the tire pressure of each wheel. The measured values are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter assembly illuminates.

When the internal circuit of a tire pressure warning valve and transmitter is malfunctioning, one of these DTCs is output.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2141 |

Transmitter ID1 Error | If an "ERROR" signal is received 3 times consecutively, the tire pressure warning valve and transmitter will be judged as defective and a DTC will be output. This will happen in situations where the inflation pressure is outside the specified range (0 to 380 kPa (0 to 3.9 kgf/cm2, 0 to 55 psi)), the temperature inside the tire is outside the specified range (-40 to 120°C (-40 to 248°F)), or an error occurs in the tire pressure warning valve and transmitter. |

Tire pressure warning valve and transmitter |

- |

| C2142 |

Transmitter ID2 Error | If an "ERROR" signal is received 3 times consecutively, the tire pressure warning valve and transmitter will be judged as defective and a DTC will be output. This will happen in situations where the inflation pressure is outside the specified range (0 to 380 kPa (0 to 3.9 kgf/cm2, 0 to 55 psi)), the temperature inside the tire is outside the specified range (-40 to 120°C (-40 to 248°F)), or an error occurs in the tire pressure warning valve and transmitter. |

Tire pressure warning valve and transmitter |

- |

| C2143 |

Transmitter ID3 Error | If an "ERROR" signal is received 3 times consecutively, the tire pressure warning valve and transmitter will be judged as defective and a DTC will be output. This will happen in situations where the inflation pressure is outside the specified range (0 to 380 kPa (0 to 3.9 kgf/cm2, 0 to 55 psi)), the temperature inside the tire is outside the specified range (-40 to 120°C (-40 to 248°F)), or an error occurs in the tire pressure warning valve and transmitter. |

Tire pressure warning valve and transmitter |

- |

| C2144 |

Transmitter ID4 Error | If an "ERROR" signal is received 3 times consecutively, the tire pressure warning valve and transmitter will be judged as defective and a DTC will be output. This will happen in situations where the inflation pressure is outside the specified range (0 to 380 kPa (0 to 3.9 kgf/cm2, 0 to 55 psi)), the temperature inside the tire is outside the specified range (-40 to 120°C (-40 to 248°F)), or an error occurs in the tire pressure warning valve and transmitter. |

Tire pressure warning valve and transmitter |

- |

HINT:

It is necessary to perform the following procedure to identify the tire pressure warning valve and transmitter that is malfunctioning because it cannot be identified by the output DTC.

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver if one of the valve and transmitters has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if one of the valve and transmitters has been replaced.

PROCEDURE

|

1. | IDENTIFY TRANSMITTER CORRESPONDING TO DTC (TIRE POSITION) |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Display the "ID Tire Position" value for each wheel using the Techstream.

(g) Refer to the following chart and check the wheel position of the DTC and transmitter match.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Position | ID1 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 2 Tire Position | ID2 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID2 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 3 Tire Position | ID3 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID3 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 4 Tire Position | ID4 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID4 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

HINT:

Refer to the following chart for the Data List items that correspond to the DTCs.

|

DTC No. | Detection Item |

Data List |

|---|---|---|

| C2141 |

Transmitter ID1 Error | ID1 Tire Position |

|

C2142 | Transmitter ID2 Error |

ID2 Tire Position |

|

C2143 | Transmitter ID3 Error |

ID3 Tire Position |

|

C2144 | Transmitter ID4 Error |

ID4 Tire Position |

|

Tester Display |

|---|

| ID 1 Tire Position |

|

ID 2 Tire Position |

|

ID 3 Tire Position |

|

ID 4 Tire Position |

| NEXT |  | REPLACE TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

DESCRIPTION

The IDs of each tire pressure warning valve and transmitter are registered to the tire pressure warning ECU and receiver.

When the ECU detects that a transmitter ID code is not registered in the ECU, this DTC is stored.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2171 |

Transmitter ID not Registered (Main) |

Transmitter ID code is not registered. (When an ID code is unregistered for 3 minutes or more) |

Tire pressure warning ECU and receiver |

- |

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

PROCEDURE

|

1. | CONFIRM REGISTRATION CONDITION (REGISTERED ID CODES) |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

HINT:

*1: Displayed only when the ID No. is not registered.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

|---|

| Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

OK:

The registered transmitter ID codes are displayed on the Techstream.

| OK |  | REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

|

| 2. |

PERFORM REGISTRATION (TRANSMITTER ID) |

(a) Perform registration.

Click here

|

| 3. |

PERFORM INITIALIZATION |

(a) Perform initialization.

Click here

|

| 4. |

CONFIRM TIRE INFLATION PRESSURE (DATA LIST) |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge)/ 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

HINT:

|

Tester Display |

|---|

| ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

|

Result | Proceed to |

|---|---|

|

All tire pressure readings are equal to specified values. |

A |

| Tire pressure values are not displayed. |

B |

| A |

| END |

| B |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

DESCRIPTION

Tire pressure warning valve and transmitter signals are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2176 |

Receiver Error | Malfunction in the tire pressure warning ECU and receiver internal circuit |

Tire pressure warning ECU and receiver |

- |

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

PROCEDURE

|

1. | CHECK DTC OUTPUT (C2176) |

(a) Clear the DTCs.

Chassis > Tire Pressure Monitor > Clear DTCs(b) Turn the engine switch off.

(c) Turn the engine switch on (IG) and check for DTCs.

Chassis > Tire Pressure Monitor > Trouble Codes|

Result | Proceed to |

|---|---|

|

C2176 is not output | A |

|

C2176 is output | B |

| A |

| END |

| B |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

DESCRIPTION

Initialization is necessary if one of the following occurs:

Tire pressure warning initialization is performed when the engine switch is on (IG), "Set Pressure" is selected on the multi-information display and the "OK" switch (steering pad switch assembly) is pressed and held.

When an initialization request signal is received, the tire pressure warning ECU and receiver blinks the tire pressure warning light in the combination meter assembly 3 times and registers the tire pressure information sent from the tire pressure warning valve and transmitters.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2177 |

Initialization not Completed |

All conditions below are met:

|

| - |

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver

if the ECU and/or one of the valve and transmitters has been replaced.

PROCEDURE

|

1. | CHECK FREQUENCY RECEIVING CONDITION |

(a) Check that the following conditions are not met:

(1) Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

HINT:

If the vehicle is located in an area such as the one described above, the tire pressure warning light may illuminate after blinking for 1 minute due to interfering radio frequencies.

(2) Devices using similar radio frequencies are used in the vehicle.

OK:

Facilities or devices that use similar radio frequencies are not located in the vicinity of the vehicle.

HINT:

Radio transmissions may be interrupted due to the surroundings, or devices installed by the user.

| NG |  | CHECK IF ANY DEVICE IS INSTALLED BY USER |

|

| 2. |

PERFORM INITIALIZATION |

(a) Perform initialization.

Click here

|

| 3. |

CONFIRM TIRE INFLATION PRESSURE (DATA LIST) |

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) Read the Data List according to the display on the Techstream.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 3 Tire Inflation Pressure |

ID3 Tire Inflation Pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

|

ID 4 Tire Inflation Pressure |

ID4 Tire Inflation Pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*1 |

HINT:

|

Tester Display |

|---|

| ID 1 Tire Inflation Pressure |

|

ID 2 Tire Inflation Pressure |

|

ID 3 Tire Inflation Pressure |

|

ID 4 Tire Inflation Pressure |

|

Result | Proceed to |

|---|---|

|

All tire pressure readings are equal to specified values. |

A |

| Tire pressure values are not displayed. |

B |

| A |

| END |

| B |

| GO TO DTC (C2121 TO C2124) |

DESCRIPTION

The tire pressure warning ECU and receiver receives signals from the combination meter assembly via CAN communication. If a malfunction occurs in this communication line, DTC C2178 is output.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2178 |

Vehicle Speed Information Communication Lost |

Communication between the combination meter assembly and tire pressure warning ECU and receiver is interrupted for 10 seconds or more. |

| - |

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

PROCEDURE

|

1. | INSPECT COMBINATION METER ASSEMBLY (ON-VEHICLE INSPECTION) |

(a) Perform On-vehicle Inspection of the meter/gauge system.

Click here

HINT:

Check the meter function by referring to On-vehicle Inspection for the combination meter assembly.

|

Result | Proceed to |

|---|---|

|

Combination meter assembly is normal |

A |

| Combination meter assembly is malfunctioning |

B |

| A |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| B |

| GO TO METER / GAUGE SYSTEM |

DESCRIPTION

The main body ECU (multiplex network body ECU) sends signals to the tire pressure warning ECU and receiver via a direct line.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2179 |

Tire Pressure Monitor ECU Communication Stop |

Communication between the main body ECU (multiplex network body ECU) and tire pressure warning ECU and receiver is interrupted for 10 seconds or more. |

| - |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver after the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver after the ECU has been replaced.

Click here

PROCEDURE

|

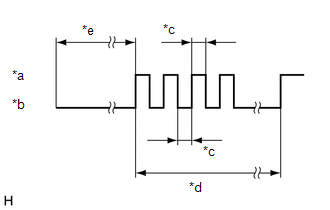

1. | INSPECT MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (OUTPUT WAVEFORM) |

| (a) Using an oscilloscope, check the waveform. NOTICE: With the connector connected, check from the backside of the connector. Standard Voltage:

|

|

|

Result | Proceed to |

|---|---|

|

Waveform is as shown in the illustration. (Waveform alternates between 9.8 V or higher and 1.2 V or less) |

A |

| Waveform does not change from 9.8 V or higher |

B |

| Waveform does not change from 1.2 V or less |

C |

| A |

| REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| B |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 2. |

CHECK TERMINAL VOLTAGE (TIRE PRESSURE WARNING ECU AND RECEIVER OUTPUT) |

(a) Disconnect the G34 main body ECU (multiplex network body ECU) connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G34-11 (PRG) - Body ground |

Engine switch on (IG) |

9.8 V or higher |

| OK |  | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 3. |

CHECK HARNESS AND CONNECTOR (TIRE PRESSURE WARNING ECU AND RECEIVER - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Turn the engine switch off.

(b) Disconnect the K11 tire pressure warning ECU and receiver connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-5 (PRG) - G34-11 (PRG) |

Always | Below 1 Ω |

|

K11-5 (PRG) or G34-11 (PRG) - Body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (POWER SUPPLY - TIRE PRESSURE WARNING ECU AND RECEIVER) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-7 (+B) - Body ground |

Always | 10 to 16 V |

|

K11-1 (IG) - Body ground |

Engine switch on (IG) |

10 to 16 V |

| OK |  | REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

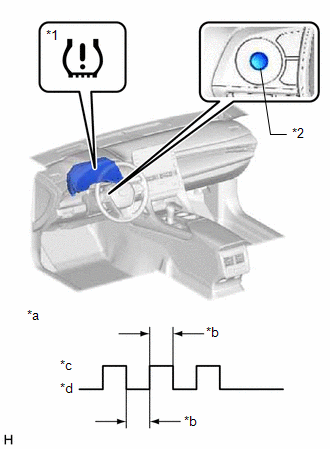

The switch circuit inside the combination meter assembly turns on and off according to the steering pad switch assembly operation.

During test mode, the tire pressure warning light blinks at 0.125 second intervals when "Set Pressure" is selected on the multi-information display, and illuminates when the "OK" switch (steering pad switch assembly) is pressed.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| C2198 |

Initialization Switch Error (for Test Diagnosis) |

Test mode procedure is performed. |

| - |

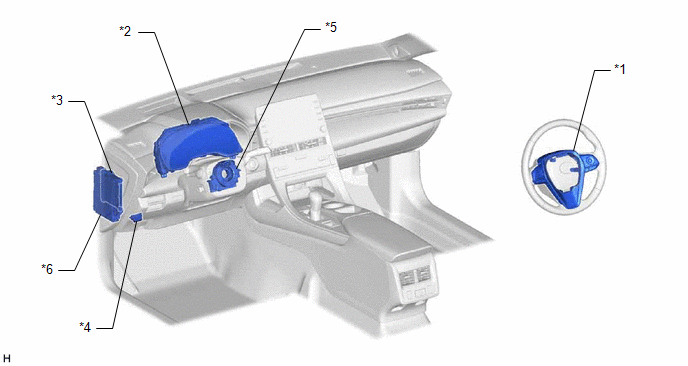

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

after registration

after registration

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

of the transmitter IDs into the tire pressure warning ECU and receiver if the ECU has been replaced.

PROCEDURE

|

1. | INSPECT STEERING PAD SWITCH ASSEMBLY |

(a) Remove the steering pad switch assembly.

Click here

(b) Inspect the steering pad switch assembly.

Click here

| NG |  | REPLACE STEERING PAD SWITCH ASSEMBLY |

|

| 2. |

INSPECT SPIRAL CABLE SUB-ASSEMBLY |

(a) Remove the spiral cable sub-assembly.

Click here

(b) Inspect the spiral cable sub-assembly.

Click here

| NG |  | REPLACE SPIRAL CABLE SUB-ASSEMBLY |

|

| 3. |

CHECK HARNESS AND CONNECTOR (SPIRAL CABLE SUB-ASSEMBLY - COMBINATION METER ASSEMBLY) |

(a) Disconnect the G17 spiral cable sub-assembly connector.

(b) Disconnect the G16 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G17-10 (+DP2) - G16-28 (MSM+) |

Always | Below 1 Ω |

|

G17-10 (+DP2) or G16-28 (MSM+) - Body ground |

Always | 10 kΩ or higher |

|

G17-11 (+DP) - G16-29 (MSTI) |

Always | Below 1 Ω |

|

G17-11 (+DP) or G16-29 (MSTI) - Body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - TIRE PRESSURE WARNING ECU AND RECEIVER) |

(a) Disconnect the K11 tire pressure warning ECU and receiver connector.

(b) Disconnect the G16 combination meter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-3 (CLSW) - G16-4 (INT) |

Always | Below 1 Ω |

|

K11-3 (CLSW) or G16-4 (INT) - Body ground |

Always | 10 kΩ or higher |

|

G16-21 (ES) - Body ground |

Always | Below 1 Ω |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

CHECK TERMINAL VOLTAGE (INT) |

(a) Connect the K11 tire pressure warning ECU and receiver connector.

(b) Disconnect the G16 combination meter assembly connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G16-4 (INT) - Body ground |

Engine switch on (IG) |

8 to 15 V |

| OK |  | GO TO METER / GAUGE SYSTEM |

| NG |  | REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

DESCRIPTION

When "Change Wheel" is selected on the multi-information display and the "OK" switch (steering pad switch assembly) is pushed and held, the system enters ID registration mode and the tire pressure warning light blinks 3 times.

The main body ECU (multiplex network body ECU) receives signals from the combination meter assembly via the CAN communication line.

WIRING DIAGRAM

PROCEDURE

| 1. |

CHECK TEST MODE (TIRE PRESSURE WARNING RESET SWITCH CHECK [DTC C2198]) |

(a) Perform Test Mode Procedure (Tire Pressure Warning Reset Switch Check (DTC C2198)).

Click here

| NEXT |  | GO TO DTC C2198 |

DATA LIST / ACTIVE TEST

READ DATA LIST

HINT:

Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

NOTICE:

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

(a) Turn the engine switch off.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

(f) According to the display on the Techstream, read the Data List.

Chassis > Tire Pressure Monitor > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Mode Status | Tire pressure warning system mode |

NORMAL or TEST | NORMAL: Normal mode TEST: Test mode | - |

|

Main Tire | Number of main tire ID to be registered |

4 or 5 | 4 displayed |

- |

| 2nd Tire |

Number of 2nd tire ID to be registered |

4 or 5 | 4 displayed |

- |

| Initialization Switch |

Tire pressure warning reset switch |

OFF or ON | OFF: "OK" switch (steering pad switch assembly) off ON: Steering pad switch assembly operated, "Set Pressure" selected on the multi-information display and "OK" switch (steering pad switch assembly) pressed and held | - |

|

Sensor ID Status | Status of ID selection |

Main or 2nd | Status of ID selection |

- |

| Initialization Switch Info |

Tire pressure warning reset switch setting information |

WITHOUT or WITH | WITH |

- |

| Initialization SW Function Information |

Tire pressure warning reset switch function information |

No Function, Auto Registered Function or Select Function |

Auto Registered Function |

- |

| Vehicle Speed |

Vehicle speed reading | min.: 0 km/h (0 mph) max.: 255 km/h (158 mph) |

Actual vehicle speed | Speed indicated on the combination meter assembly |

|

Registered ID 1 Code | Registered ID1 code |

min.: 0 max.: FFFFFFF*1 |

ID No. registered for transmitter ID1 displayed |

- |

| Registered ID 2 Code |

Registered ID2 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID2 displayed |

- |

| Registered ID 3 Code |

Registered ID3 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID3 displayed |

- |

| Registered ID 4 Code |

Registered ID4 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID4 displayed |

- |

| Registered ID 5 Code |

Registered ID5 code | min.: 0 max.: FFFFFFF*1 | ID No. registered for transmitter ID5 displayed |

*3 |

| ID 1 Tire Inflation Pressure |

ID1 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*2 |

|

ID 2 Tire Inflation Pressure |

ID2 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*2 |

|

ID 3 Tire Inflation Pressure |

ID3 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*2 |

|

ID 4 Tire Inflation Pressure |

ID4 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

If N/A is displayed, data has not been received.*2 |

|

ID 5 Tire Inflation Pressure |

ID5 tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Actual tire inflation pressure |

|

| Threshold of Low-pressure (Lower Limit) |

Tire inflation pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Specified tire pressure warning threshold lower limit displayed |

If N/A is displayed, data has not been received.*2 |

|

ID 1 Initial Threshold of Low-pressure |

ID1 initial threshold of low-pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Tire pressure after initialization |

- |

| ID 2 Initial Threshold of Low-pressure |

ID2 initial threshold of low-pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Tire pressure after initialization |

- |

| ID 3 Initial Threshold of Low-pressure |

ID3 initial threshold of low-pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Tire pressure after initialization |

- |

| ID 4 Initial Threshold of Low-pressure |

ID4 initial threshold of low-pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Tire pressure after initialization |

- |

| ID 5 Initial Threshold of Low-pressure |

ID5 initial threshold of low-pressure |

min.: Absolute pressure (abs) / 0 kPa (0 kgf/cm2, 0 psi), Relative pressure (Gauge) / 0 kPa (0 kgf/cm2, 0 psi) max.: Absolute pressure (abs) / 480 kPa (4.9 kgf/cm2, 70 psi), Relative pressure (Gauge) / 380 kPa (3.9 kgf/cm2, 55 psi) |

Tire pressure after initialization |

*3 |

| ID 1 Temperature in Tire |

ID1 temperature in tire |

min.: -40°C (-40°F) max.: 120°C (248°F) |

Actual tire temperature |

If -40°C (-40°F) is displayed, data has not been received. |

|

ID 2 Temperature in Tire |

ID2 temperature in tire |

min.: -40°C (-40°F) max.: 120°C (248°F) |

Actual tire temperature |

If -40°C (-40°F) is displayed, data has not been received. |

|

ID 3 Temperature in Tire |

ID3 temperature in tire |

min.: -40°C (-40°F) max.: 120°C (248°F) |

Actual tire temperature |

If -40°C (-40°F) is displayed, data has not been received. |

|

ID 4 Temperature in Tire |

ID4 temperature in tire |

min.: -40°C (-40°F) max.: 120°C (248°F) |

Actual tire temperature |

If -40°C (-40°F) is displayed, data has not been received. |

|

ID 5 Temperature in Tire |

ID5 temperature in tire |

min.: -40°C (-40°F) max.: 120°C (248°F) |

Actual tire temperature |

|

| ID 1 Tire Position |

ID1 Tire Position | No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 2 Tire Position | ID2 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 3 Tire Position | ID3 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 4 Tire Position | ID4 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 5 Tire Position | ID5 Tire Position |

No Information or FL or FR or RL or RR or Spare or Judging |

ID1 tire position is displayed |

|

| ID 1 - FL Wheel Speed Synchronization Count |

ID1 - FL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 1 - FR Wheel Speed Synchronization Count |

ID1 - FR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 1 - RL Wheel Speed Synchronization Count |

ID1 - RL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 1 - RR Wheel Speed Synchronization Count |

ID1 - RR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 2 - FL Wheel Speed Synchronization Count |

ID2 - FL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 2 - FR Wheel Speed Synchronization Count |

ID2 - FR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 2 - RL Wheel Speed Synchronization Count |

ID2 - RL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 2 - RR Wheel Speed Synchronization Count |

ID2 - RR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 3 - FL Wheel Speed Synchronization Count |

ID3 - FL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 3 - FR Wheel Speed Synchronization Count |

ID3 - FR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 3 - RL Wheel Speed Synchronization Count |

ID3 - RL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 3 - RR Wheel Speed Synchronization Count |

ID3 - RR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 4 - FL Wheel Speed Synchronization Count |

ID4 - FL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 4 - FR Wheel Speed Synchronization Count |

ID4 - FR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 4 - RL Wheel Speed Synchronization Count |

ID4 - RL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 4 - RR Wheel Speed Synchronization Count |

ID4 - RR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

- |

| ID 5 - FL Wheel Speed Synchronization Count |

ID5 - FL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

*3 |

| ID 5 - FR Wheel Speed Synchronization Count |

ID5 - FR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

*3 |

| ID 5 - RL Wheel Speed Synchronization Count |

ID5 - RL Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

*3 |

| ID 5 - RR Wheel Speed Synchronization Count |

ID5 - RR Wheel Speed Synchronization Count |

min.: 0, max.: 255 | Actual Synchronization Count |

*3 |

| Last Time ID Registered mode |

Method for registering currently registered ID |

Manual ID Registered, Not Registered or Auto ID Registered |

Displays method for registering currently registered ID |

- |

| [FLASH] Auto ID Registered FL Wheel Judgment Status |

FL wheel registration status during automatic ID registration (FLASH) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Driving distance is updated and recorded every 10 minutes |

|

[FLASH] Auto ID Registered FR Wheel Judgment Status |

FR wheel registration status during automatic ID registration (FLASH) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Driving distance is updated and recorded every 10 minutes |

|

[FLASH] Auto ID Registered RL Wheel Judgment Status |

RL wheel registration status during automatic ID registration (FLASH) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Driving distance is updated and recorded every 10 minutes |

|

[FLASH] Auto ID Registered RR Wheel Judgment Status |

RR wheel registration status during automatic ID registration (FLASH) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

Driving distance is updated and recorded every 10 minutes |

|

[FLASH] Auto ID Registered Spare Wheel Judgment Status |

Spare wheel registration status during automatic ID registration (FLASH) |

Fixed, Under a Judgment of Side by Side Car Influence or Under a Judgment, Not Registered |

Actual registration status |

|