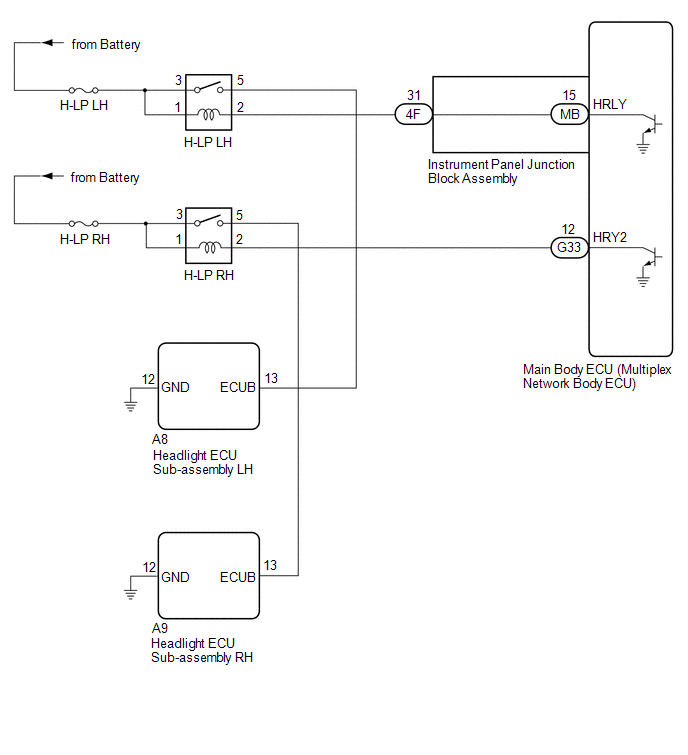

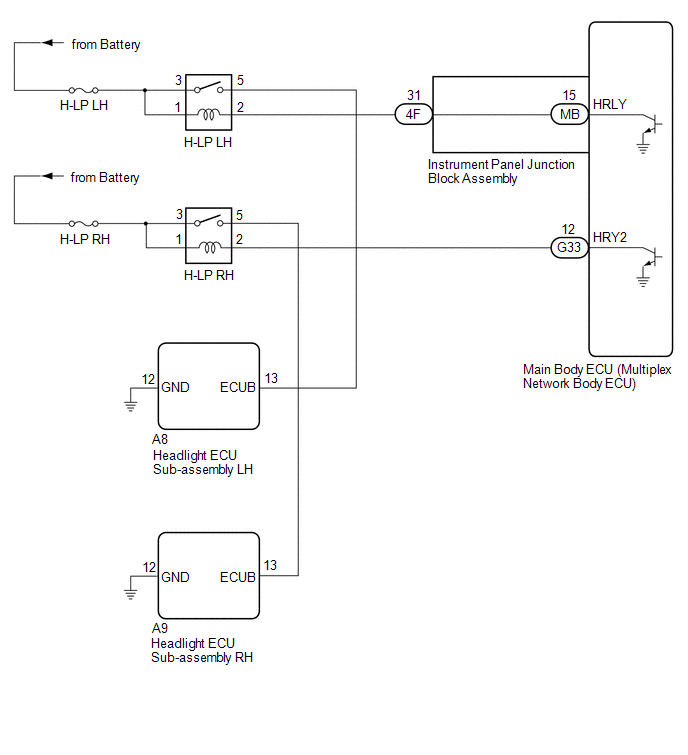

DESCRIPTION The headlight ECU sub-assembly operates using the power source voltage input from the IG terminal and ECUB terminal.

The

power source voltage of the ECUB terminal is supplied when the main

body ECU (multiplex network body ECU) turns the ECUB power supply relay

(H-LP LH relay and H-LP RH relay) to ON. The

headlight ECU sub-assembly compares the power source voltage supply

condition of the IG terminal and ECUB terminal and monitors the result. HL AutoLeveling |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

DTC Output from | |

B242F | Open in B Power Line |

- The engine switch is on (IG).

- No power source voltage supplied to ECUB terminal while power source voltage being supplied to IG terminal

|

- Headlight ECU sub-assembly LH

- Harness or connector

- H-LP LH relay

- Instrument panel junction block assembly

- Main body ECU (multiplex network body ECU)

| Headlight ECU sub-assembly LH | HL AutoLeveling (Sub) |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

DTC Output from | |

B242F | Open in B Power Line |

- The engine switch is on (IG).

- No power source voltage supplied to ECUB terminal while power source voltage being supplied to IG terminal

|

- Headlight ECU sub-assembly RH

- Harness or connector

- H-LP RH relay

- Main body ECU (multiplex network body ECU)

| Headlight ECU sub-assembly RH | WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before replacing the main body ECU (multiplex network body ECU), refer to Registration.

Click here

- If the headlight ECU sub-assembly LH has been replaced, it is necessary

to synchronize the vehicle information the headlight ECU sub-assembly

LH.

Click here

PROCEDURE (a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG). (c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / HL AutoLeveling or HL AutoLeveling (Sub) / Trouble Codes.

(e) Clear the DTCs. Body Electrical > HL AutoLeveling > Clear DTCs Body Electrical > HL AutoLeveling (Sub) > Clear DTCs

|

NEXT |

| |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG). (c) Wait 10 seconds or more.

(d) Turn the Techstream on. (e) Enter the following menus: Body Electrical / HL AutoLeveling or HL AutoLeveling (Sub) / Trouble Codes.

(f) Check for DTCs. Body Electrical > HL AutoLeveling > Trouble Codes Body Electrical > HL AutoLeveling (Sub) > Trouble Codes

OK: DTC B242F is not output. |

Result | Proceed to | |

OK | A | |

NG (DTC output from headlight ECU sub-assembly LH) |

B | | NG (DTC output from headlight ECU sub-assembly RH) |

C |

| A |

| USE SIMULATION METHOD TO CHECK |

| C |

| GO TO STEP 10 |

|

B |

| |

| 3. |

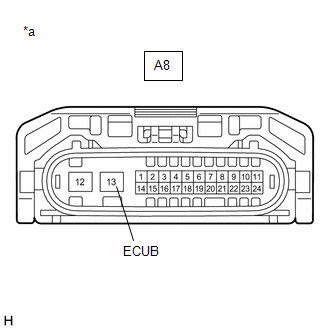

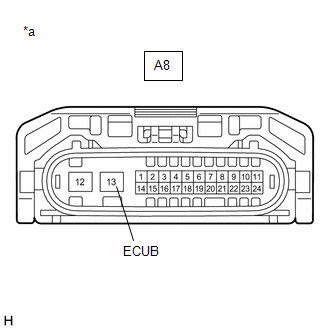

INSPECT HEADLIGHT ECU SUB-ASSEMBLY LH (ECUB TERMINAL VOLTAGE) |

|

*a | Front view of wire harness connector

(to Headlight ECU Sub-assembly LH) | (a) Disconnect the A8 headlight ECU sub-assembly LH connector.

(b) Measure the voltage according to the value(s) in the table below. Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

A8-13 (ECUB) - Body ground |

Engine switch on (IG) |

9.5 to 14 V |

| NG |

| GO TO STEP 5 |

|

OK |

| |

| 4. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT ECU SUB-ASSEMBLY LH - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A8-12 (GND) - Body ground |

Always | Below 1 Ω |

| OK |

| REPLACE HEADLIGHT ECU SUB-ASSEMBLY LH |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

(a) Inspect the H-LP LH relay.

Click here

| NG |

| REPLACE H-LP LH RELAY |

|

OK |

| |

| 6. |

CHECK HARNESS AND CONNECTOR (H-LP LH RELAY - HEADLIGHT ECU SUB-ASSEMBLY LH) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

5 (H-LP LH relay) - A8-13 (ECUB) |

Always | Below 1 Ω | |

5 (H-LP LH relay) or A8-13 (ECUB) - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 7. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - H-LP LH RELAY) |

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

1 (H-LP LH relay) - Body ground |

Always | 11 to 14 V | |

3 (H-LP LH relay) - Body ground |

Always | 11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 8. |

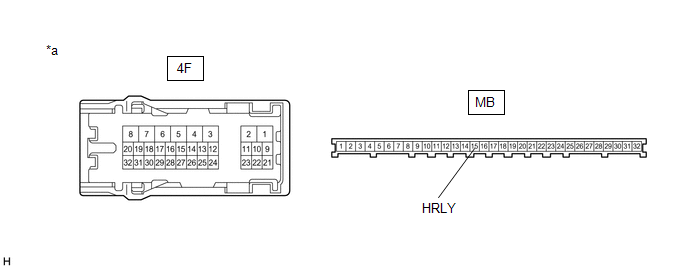

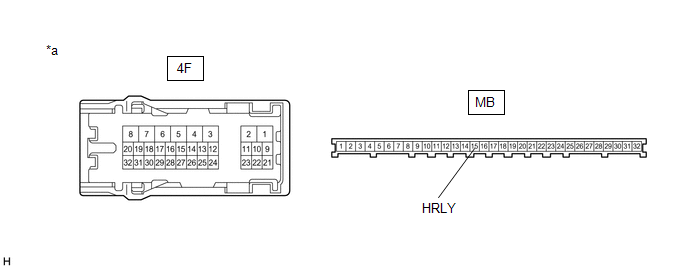

CHECK HARNESS AND CONNECTOR (H-LP LH RELAY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 4F instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

2 (H-LP LH relay) - 4F-31 |

Always | Below 1 Ω | |

2 (H-LP LH relay) or 4F-31 - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 9. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

*a | Component without harness connected

(Instrument Panel Junction Block Assembly) |

- | - |

(a) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

Click here  (b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

4F-31 - MB-15 (HRLY) |

Always | Below 1 Ω |

| OK |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG |

| REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

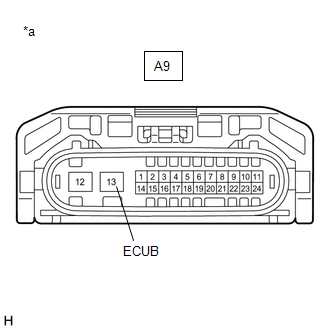

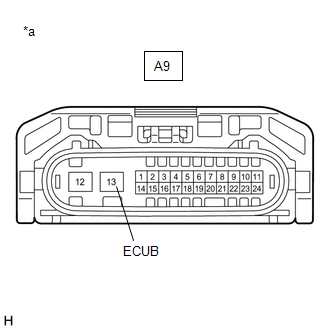

| 10. |

INSPECT HEADLIGHT ECU SUB-ASSEMBLY RH (ECUB TERMINAL VOLTAGE) |

|

*a | Front view of wire harness connector

(to Headlight ECU Sub-assembly RH) | (a) Disconnect the A9 headlight ECU sub-assembly RH connector.

(b) Measure the voltage according to the value(s) in the table below. Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

A9-13 (ECUB) - Body ground |

Engine switch on (IG) |

9.5 to 14 V |

| NG |

| GO TO STEP 12 |

|

OK |

| |

| 11. |

CHECK HARNESS AND CONNECTOR (HEADLIGHT ECU SUB-ASSEMBLY RH - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A9-12 (GND) - Body ground |

Always | Below 1 Ω |

| OK |

| REPLACE HEADLIGHT ECU SUB-ASSEMBLY RH |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 12. |

INSPECT H-LP RH RELAY | (a) Inspect the H-LP RH relay.

Click here

| NG |

| REPLACE H-LP RH RELAY |

|

OK |

| |

| 13. |

CHECK HARNESS AND CONNECTOR (H-LP RH RELAY - HEADLIGHT ECU SUB-ASSEMBLY RH) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

5 (H-LP RH relay) - A9-13 (ECUB) |

Always | Below 1 Ω | |

5 (H-LP RH relay) or A9-13 (ECUB) - Body ground |

Always | 10 kΩ or higher |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 14. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - H-LP RH RELAY) |

(a) Measure the voltage according to the value(s) in the table below. Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

1 (H-LP RH relay) - Body ground |

Always | 11 to 14 V | |

3 (H-LP RH relay) - Body ground |

Always | 11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

OK |

| |

| 15. |

CHECK HARNESS AND CONNECTOR (H-LP RH RELAY - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the G33 main body ECU (multiplex network body ECU) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

2 (H-LP RH relay) - G33-12 (HRY2) |

Always | Below 1 Ω | |

2 (H-LP RH relay) or G33-12 (HRY2) - Body ground |

Always | 10 kΩ or higher |

| OK |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR | |