DESCRIPTION

If none of the switch indicators on the air conditioning control panel (radio and display receiver assembly) illuminate, the following factors may be the cause.

|

Symptom | Factor |

|---|---|

|

A/C switch indicator does not illuminate |

|

PROCEDURE

| 1. |

CHECK MALFUNCTION STATUS |

(a) Check the malfunction status of switch indicators on the air conditioning control panel (radio and display receiver assembly).

| Result | Proceed to |

|---|---|

|

Indicators are not always illuminated |

A |

| Indicators are not illuminated only immediately after starting the engine |

B |

| B |

| GO TO INITIALIZATION |

|

| 2. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Ambient Temp Sensor | Thermistor assembly |

Min.: -23.30°C (-9.94°F) Max.: 65.95°C (150.71°F) |

Actual ambient temperature displayed |

Thermistor assembly circuit malfunction

|

|

Tester Display |

|---|

| Ambient Temp Sensor |

OK:

The value displayed is 0°C (32°F) or higher.

| OK |  | INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET |

| NG |  | GO TO OTHER DIAGNOSIS PROCEDURE (Ambient Temperature Display System) |

DESCRIPTION

When the engine is running, If refrigerant pressure does not decrease when the A/C switch is turned off, the following factors may be the cause.

|

Symptom | Factor |

|---|---|

|

|

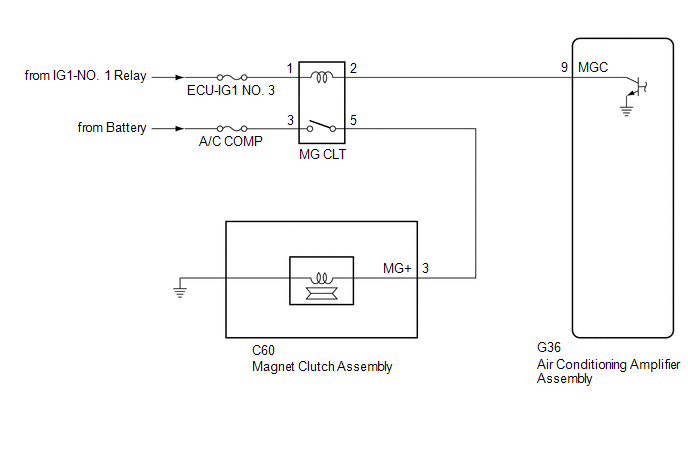

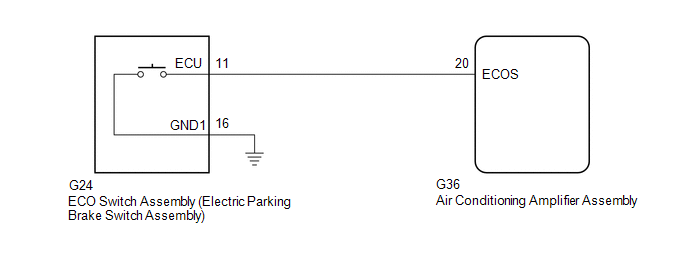

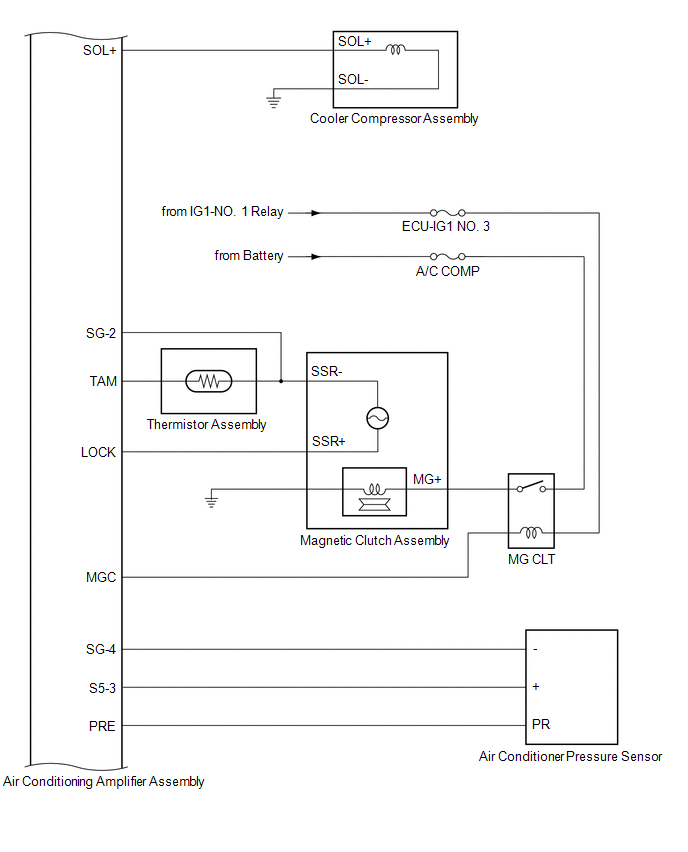

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

| 1. |

INSPECT MG CLT RELAY |

(a) Inspect the MG CLT relay.

Click here

| NG |  | REPLACE MG CLT RELAY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (MG CLT RELAY - POWER SOURCE) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3 (MG CLT relay) - Body ground |

Always | 11 to 14 V |

|

1 (MG CLT relay) - Body ground |

Engine switch off | Below 1 V |

|

1 (MG CLT relay) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK HARNESS AND CONNECTOR (MG CLT RELAY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

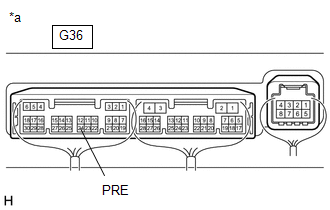

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

2 (MG CLT relay) - G36-9 (MGC) |

Always | Below 1 Ω |

|

2 (MG CLT relay) or G36-9 (MGC) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (MG CLT RELAY - MAGNET CLUTCH ASSEMBLY AND BODY GROUND) |

(a) Disconnect the C60 magnet clutch assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

5 (MG CLT relay) - C60-3 (MG+) |

Always | Below 1 Ω |

|

5 (MG CLT relay) or C60-3 (MG+) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

CHECK HARNESS AND CONNECTOR (MAGNET CLUTCH ASSEMBLY - BODY GROUND) |

(a) Install the MG CLT relay.

(b) Connect the C60 compressor assembly with magnetic clutch connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

C60-3 (MG+) - Body ground |

Engine running (A/C switch: Off) |

Below 1 V |

| OK |  | REPLACE MAGNET CLUTCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

If the air outlet mode does not change even though the air outlet display changes, the following factors may be the cause.

|

Symptom | Factor |

|---|---|

|

Air outlet mode cannot be changed

|

|

PROCEDURE

| 1. |

CHECK AIR OUTLET SERVO MOTOR |

(a) Confirm for which seat the air outlet mode cannot be changed.

|

Result | Proceed to |

|---|---|

|

The air outlet mode for the driver seat cannot be changed |

A |

| The air outlet mode for the front passenger seat cannot be changed | |

|

The air outlet mode for the rear seats cannot be changed |

B |

| B |

| GO TO STEP 4 |

|

| 2. |

CHECK NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

(a) Check that the No. 1 air conditioning radiator damper servo sub-assembly is installed correctly.

OK:

The No. 1 air conditioning radiator damper servo sub-assembly is installed correctly.

| NG |  | INSTALL NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

|

| 3. |

CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

B1443 is not output | A |

|

B1443 is output | B |

| A |

| REPLACE AIR CONDITIONING RADIATOR ASSEMBLY |

| B |

| GO TO DTC B1443 |

| 4. |

CHECK NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

(a) Check that the No. 2 air conditioning radiator damper servo sub-assembly is installed correctly.

OK:

The No. 2 air conditioning radiator damper servo sub-assembly is installed correctly.

| NG |  | INSTALL NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

|

| 5. |

CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

B1449 is not output | A |

|

B1449 is output | B |

| A |

| REPLACE AIR CONDITIONING RADIATOR ASSEMBLY |

| B |

| GO TO DTC B1449 |

DESCRIPTION

If the temperature of the air that blows from the left and right front registers differs, even though the same temperature is set for both sides, the following factors may be the cause.

|

Symptom | Factor |

|---|---|

|

Temperature of outlet air is cooler on left or right side

|

|

| Temperature of outlet air is warmer on left or right side

|

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

w/ Cornering Light: Click here

w/o Cornering Light: Click here

Click here

PROCEDURE

|

1. | CHECK WHEN MALFUNCTION OCCURS |

| Result |

Proceed to |

|---|---|

| When using cooling function |

A |

| When using heater function |

B |

| B |

| GO TO STEP 6 |

|

| 2. |

PERFORM REFRIGERANT SHORTAGE CHECK |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Utility / Refrigerant Gas Volume Check.

Body Electrical > Air Conditioner > Utility|

Tester Display |

|---|

| Refrigerant Gas Volume Check |

(e) Check that the following conditions are met and perform the refrigerant shortage check according to the display on the Techstream.

Measurement Condition:|

Item | Condition |

|---|---|

|

A/C switch | On |

|

Ambient temperature* |

0 to 49°C (32 to 120°F) |

|

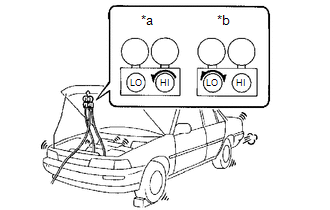

Blower speed | HI |

*: If the ambient temperature is not within the range shown, do not perform this check.

|

Result | Amount of Refrigerant |

|---|---|

|

Refrigerant correct | Correct |

|

Refrigerant shortage |

Insufficient |

OK:

"Refrigerant correct" is displayed on the Techstream.

| NG |  | CHARGE SYSTEM WITH REFRIGERANT |

|

| 3. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 and 257 pulses |

|

Air Mix Servo Targ Pulse(P) |

No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 255 and 347 pulses |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(D) |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(P) |

OK:

Each damper servo motor operates.

| NG |  | GO TO DTC TROUBLESHOOTING PROCEDURE FOR MALFUNCTIONING DAMPER SERVO MOTOR |

|

| 4. |

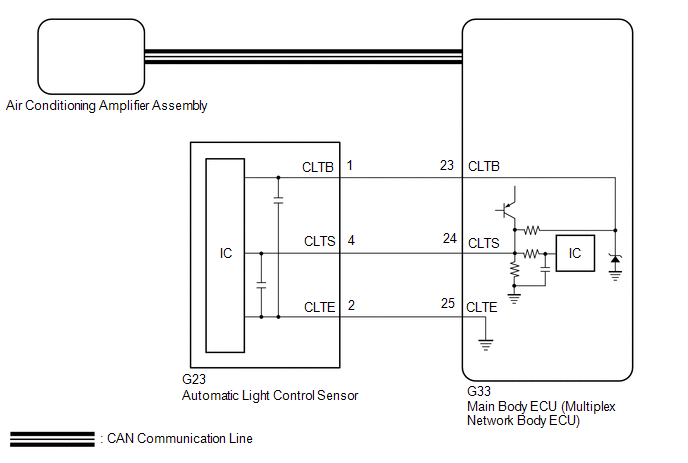

CHECK HARNESS AND CONNECTOR (AUTOMATIC LIGHT CONTROL SENSOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the G23 automatic light control sensor connector.

(b) Disconnect the G33 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G23-1 (CLTB) - G33-23 (CLTB) |

Always | Below 1 Ω |

|

G23-2 (CLTE) - G33-25 (CLTE) |

Always | Below 1 Ω |

|

G23-4 (CLTS) - G33-24 (CLTS) |

Always | Below 1 Ω |

|

G23-1 (CLTB) or G33-23 (CLTB) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

G23-2 (CLTE) or G33-25 (CLTE) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

G23-4 (CLTS) or G33-24 (CLTS) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

INSPECT AUTOMATIC LIGHT CONTROL SENSOR |

(a) Remove the automatic light control sensor.

Click here

(b) Inspect the automatic light control sensor.

Click here

| OK |  | INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET |

| NG |  | REPLACE AUTOMATIC LIGHT CONTROL SENSOR |

| 6. |

BLEED AIR FROM COOLING SYSTEM |

(a) Bleed air from cooling system.

Click here

|

| 7. |

CHECK OPERATION (AIR CONDITIONING SYSTEM) |

(a) Set the same temperature for the left and right sides and check that the air that blows from the left and right front registers is the same temperature.

OK:

The air from the left and right front registers is the same temperature.

| OK |  | END (MALFUNCTION DUE TO AIR IN COOLING SYSTEM) |

|

| 8. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 and 257 pulses |

|

Air Mix Servo Targ Pulse(P) |

No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 255 and 347 pulses |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(D) |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(P) |

OK:

Each damper servo motor operates.

| OK |  | REPLACE HEATER RADIATOR UNIT SUB-ASSEMBLY |

| NG |  | GO TO DTC TROUBLESHOOTING PROCEDURE FOR MALFUNCTIONING DAMPER SERVO MOTOR |

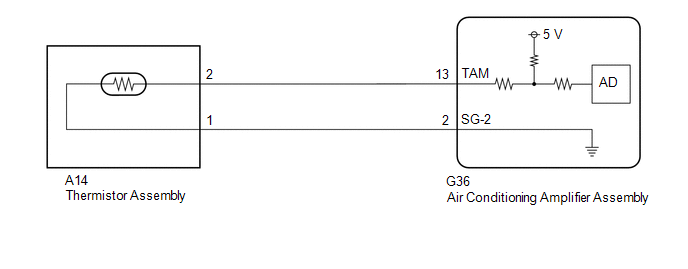

DESCRIPTION

The thermistor assembly is installed in front of the cooler condenser assembly to detect the ambient temperature, which is used to control the automatic air conditioning system. The thermistor assembly detects fluctuations in the ambient temperature and sends it as a signal to the combination meter assembly. This data is used for controlling the cabin temperature. The resistance of the thermistor assembly changes in accordance with the ambient temperature. As the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases. The combination meter assembly applies voltage (5 V) to the thermistor assembly and detects voltage changes due to changes in the resistance of the thermistor assembly.

NOTICE:

The thermistor assembly detects the ambient temperature in its vicinity, not the ambient temperature around the vehicle. Depending on factors such as radiant heat from the engine room and the vehicle speed, the ambient temperature detected by the thermistor assembly may differ from the ambient temperature displayed on the multi-information display in the combination meter assembly. For example:

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. | CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B1412 is not output |

A |

| DTC B1412 is output |

B |

| B |

| GO TO DTC B1412 |

|

| 2. |

INSPECT THERMISTOR ASSEMBLY |

(a) Remove the thermistor assembly.

Click here

(b) Inspect the thermistor assembly.

Click here

| NG |  | REPLACE THERMISTOR ASSEMBLY |

|

| 3. |

CHECK HARNESS AND CONNECTOR (THERMISTOR ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A14-2 - G36-13 (TAM) |

Always | Below 1 Ω |

|

A14-1 - G36-2 (SG-2) |

Always | Below 1 Ω |

|

A14-2 or G36-13 (TAM) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

A14-1 or G36-2 (SG-2) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK VALUE OF AMBIENT TEMPERATURE DETECTED BY THERMISTOR ASSEMBLY |

(a) Disconnect the cable from the negative (-) battery terminal and wait for at least 90 seconds.

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

Click here

HINT:

The air conditioning amplifier assembly stores the value of the last ambient temperature detected by the thermistor assembly before the engine switch was turned off for up to 1 hour after the engine switch is turned off. It is necessary to clear this value.

(b) Connect the cable to the negative (-) battery terminal.

(c) Measure and make a note of the ambient temperature near the thermistor assembly using a thermometer.

NOTICE:

(d) Make a note of the ambient temperature displayed on the multi-information display in the combination meter assembly.

(e) Compare the value of the ambient temperature measured by the thermometer and the thermistor assembly.

OK:

The value of the ambient temperature measured by the thermometer and the thermistor assembly are almost the same.

| OK |  | END |

| NG |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

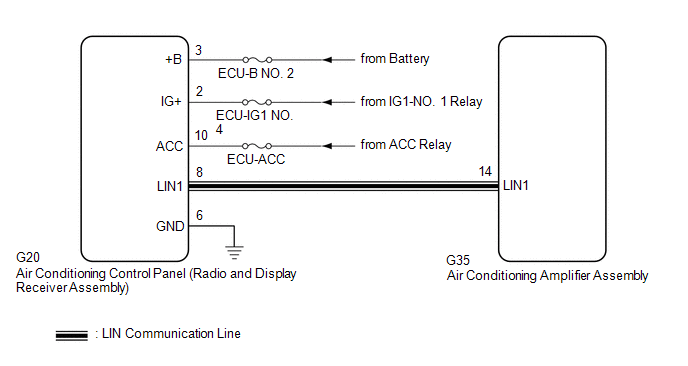

DESCRIPTION

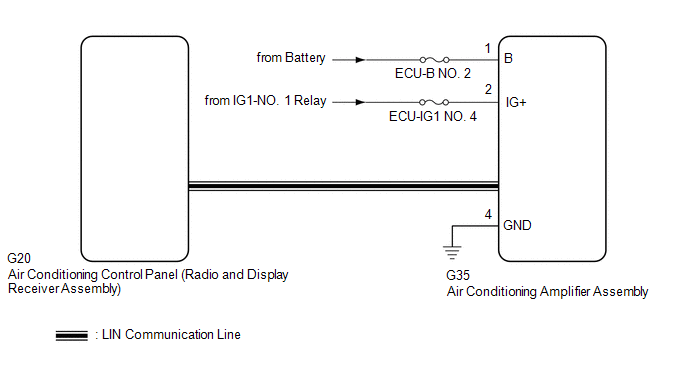

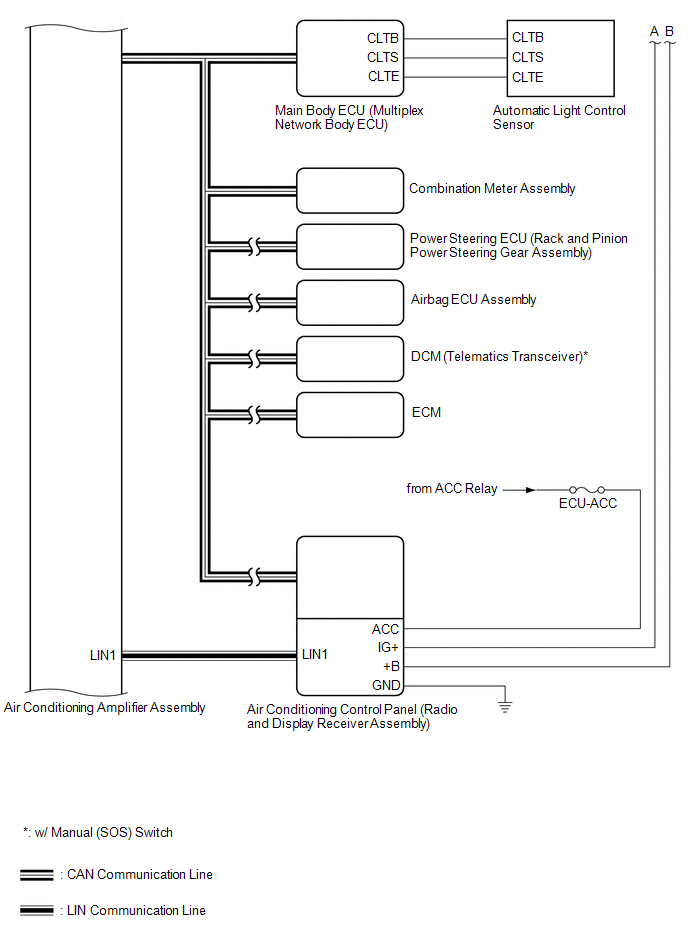

The air conditioning control panel (radio and display receiver assembly) communicates with the air conditioning amplifier assembly via LIN communication.

If a malfunction occurs in the LIN communication system, the air conditioning amplifier assembly will not operate, even if the air conditioning control panel (radio and display receiver assembly) is operated.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B14B2 |

Lost Communication with Front Panel LIN |

Lost communication with air conditioning control assembly |

| Memorized (10 sec. or more)* |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

| 1. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONING CONTROL PANEL (RADIO AND DISPLAY RECEIVER ASSEMBLY) - POWER SOURCE AND BODY GROUND) |

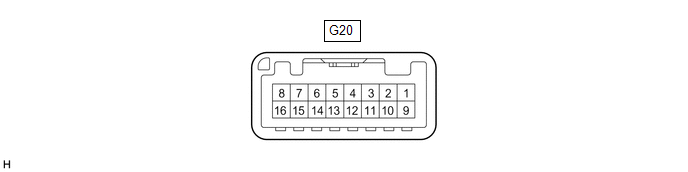

(a) Disconnect the G20 air conditioning control panel (radio and display receiver assembly) connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G20-3 (+B) - Body ground |

Engine switch off | 11 to 14 V |

|

G20-2 (IG+) - Body ground |

Engine switch on (IG) |

11 to 14 V |

|

G20-10 (ACC) - Body ground |

Engine switch on (ACC) |

11 to 14 V |

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G20-6 (GND) - Body ground |

Always | Below 1 Ω |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 2. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONING CONTROL PANEL (RADIO AND DISPLAY RECEIVER ASSEMBLY) - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

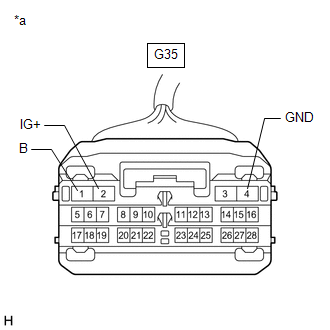

(a) Disconnect the G35 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G20-8 (LIN1) - G35-14 (LIN1) |

Always | Below 1 Ω |

|

G20-8 (LIN1) or G35-14 (LIN1) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

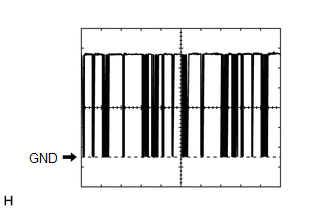

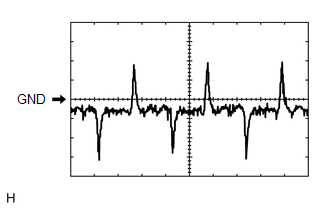

| 3. |

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

(a) Connect the G35 air conditioning amplifier assembly connector.

(b) Turn the engine switch on (IG).

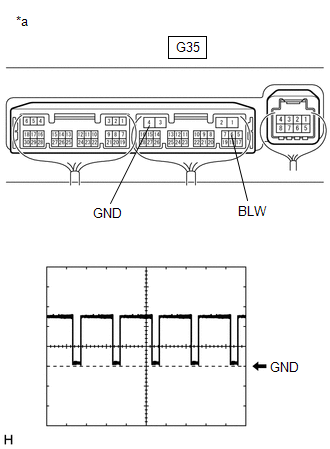

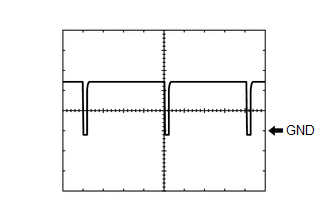

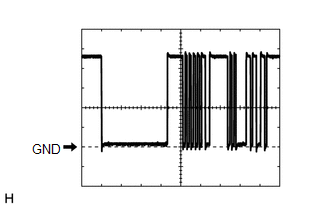

(c) Using an oscilloscope, check the waveform.

|

Item | Content |

|---|---|

|

Terminal No. | G35-14 (LIN1) - Body ground |

|

Tool Setting | 2 V/DIV., 20 ms./DIV. |

|

Condition | Engine switch on (IG) |

OK:

Waveform is similar to that shown in the illustration.

| NG |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

| 4. |

INSPECT AIR CONDITIONING CONTROL PANEL (RADIO AND DISPLAY RECEIVER ASSEMBLY) |

|

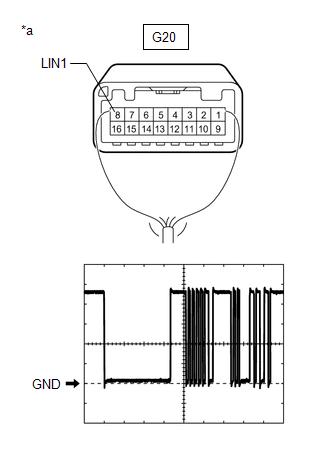

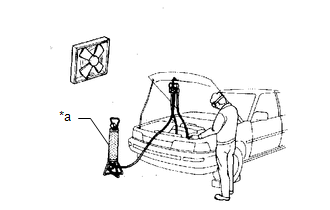

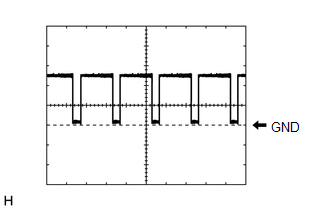

*a | Component with harness connected (Air Conditioning Control Panel (Radio and Display Receiver Assembly)) |

(a) Connect the G20 air conditioning control panel (radio and display receiver assembly) connector.

(b) Turn the engine switch on (IG).

(c) Using an oscilloscope, check the waveform.

|

Item | Content |

|---|---|

|

Terminal No. | G20-8 (LIN1) - Body ground |

|

Tool Setting | 2 V/DIV., 20 ms./DIV. |

|

Condition | Engine switch on (IG) |

OK:

Waveform is similar to that shown in the illustration.

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPLACE AIR CONDITIONING CONTROL PANEL (RADIO & DISPLAY RECEIVER ASSEMBLY) |

DESCRIPTION

This DTC is stored if the amount of refrigerant in the air conditioning system is insufficient.

The air conditioning amplifier assembly receives the ambient temperature signal, refrigerant pressure signal, etc. from various sensors.

Based on these signals, the air conditioning amplifier assembly detects the amount of refrigerant.

If the amount of refrigerant is insufficient, the A/C switch indicator will turn off and the air conditioning system will stop operating.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B14B8 |

Refrigerant Shortage | The following condition is detected in the normal operation refrigerant shortage check: Amount of refrigerant is insufficient |

| Memorized (10 min. or more)* |

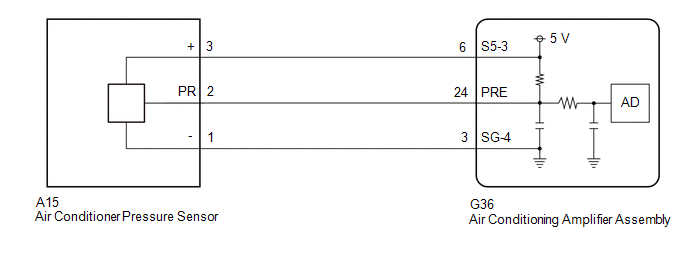

WIRING DIAGRAM

PROCEDURE

| 1. |

CHECK REFRIGERANT PRESSURE |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

|

Tester Display |

|---|

| Regulator Pressure Sensor |

(f) Install a manifold gauge set.

Click here

(g) Read the manifold gauge set with the following conditions met.

Measurement Condition:|

Item | Condition |

|---|---|

|

Vehicle doors | Fully open |

|

Temperature setting | MAX COLD |

|

Blower speed | HI |

|

A/C switch | On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

30 to 35°C (86 to 95°F) |

Standard Pressure:

Low pressure side

150 to 250 kPa (1.5 to 2.5 kgf/cm2, 22 to 36 psi)

High pressure side

1370 to 1570 kPa (14 to 16 kgf/cm2, 199 to 228 psi)

(h) Compare the values displayed in the Data List and on the manifold gauge set.

OK:

The values displayed in the Data List and on the manifold gauge set match.

| OK |  | INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET |

|

| 2. |

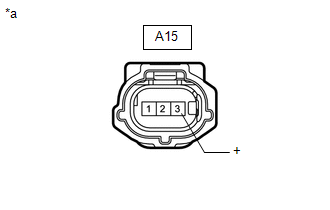

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

|

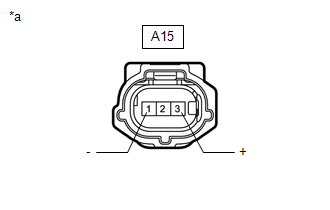

*a | Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Disconnect the A15 air conditioner pressure sensor connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-3 (+) - Body ground |

Engine switch on (IG) |

4.75 to 5.25 V |

| NG |  | GO TO STEP 7 |

|

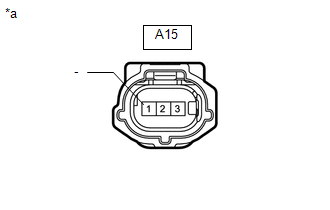

| 3. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - BODY GROUND) |

|

*a | Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-1 (-) - Body ground |

Always | Below 1 Ω |

| NG |  | GO TO STEP 6 |

|

| 4. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-2 (PR) - G36-24 (PRE) |

Always | Below 1 Ω |

|

A15-2 (PR) or G36-24 (PRE) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

INSPECT AIR CONDITIONER PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT) |

|

*a | Component with harness connected (Air Conditioning Amplifier Assembly) |

(a) Measure the voltage with the following conditions met.

Measurement Condition:|

Item | Condition |

|---|---|

|

Vehicle doors | Fully open |

|

Temperature setting | MAX COLD |

|

Blower speed | HI |

|

A/C switch | On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

25 to 35°C (77 to 95°F) |

NOTICE:

HINT:

When the ambient air temperature is low (below -1.5°C (29.3°F)), the compressor with pulley will be stopped, due to inputs of the thermistor assembly and No. 1 cooler thermistor, to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

(1) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G36-24 (PRE) - Body ground |

Engine switch on (IG) (A/C switch: On) |

0.74 to 4.61 V |

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(f) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

|

Tester Display |

|---|

| Regulator Pressure Sensor |

OK:

The voltage and value displayed in the Data List change.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (The voltage changes but the value displayed in the Data List does not change.) | |

|

NG (The voltage does not change.) |

B |

| A |

| REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| B |

| REPLACE AIR CONDITIONER PRESSURE SENSOR |

| 6. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-1 (-) - G36-3 (SG-4) |

Always | Below 1 Ω |

|

A15-1 (-) or G36-3 (SG-4) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 7. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-3 (+) - G36-6 (S5-3) |

Always | Below 1 Ω |

|

A15-3 (+) or G36-6 (S5-3) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

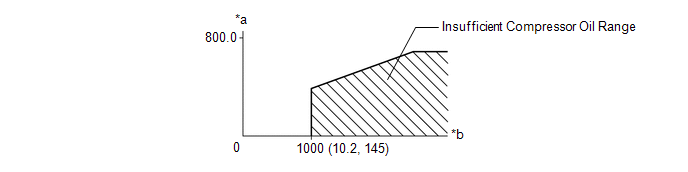

This DTC is stored if the amount of refrigerant in the in the air conditioning system exceeds a threshold. The air conditioning amplifier assembly judges whether the amount of refrigerant is appropriate based on the detected refrigerant pressure and cooler compressor assembly operation current. If the amount of refrigerant in the system is determined to have exceeded a threshold, operation of the cooler compressor assembly will be stopped, and will remain stopped even if the engine switch is turned off and then the engine is restarted.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B14BD |

Refrigerant Overabundance Filling Malfunction |

All of the following conditions are met 2 times or more in the same trip:

|

| Memorized (60 sec. or more)* |

|

*a | Electric Current (mA) |

*b | Refrigerant Pressure kPa (kgf/cm2, psi) |

PROCEDURE

| 1. |

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM |

(a) Recover the refrigerant from the air conditioning system using a refrigerant recovery unit.

Click here

|

| 2. |

CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

(a) Charge the air conditioning system with refrigerant.

Click here

| NEXT |  |

END |

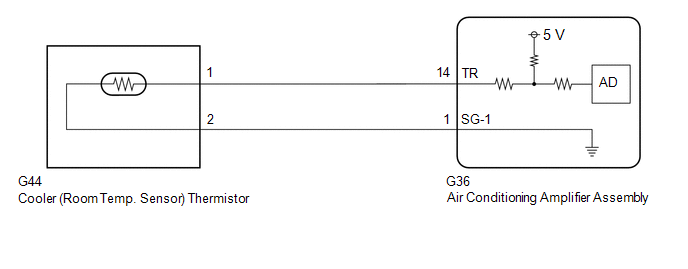

DESCRIPTION

The cooler (room temp. sensor) thermistor is installed in the instrument panel to detect the cabin temperature, which is used to control the air conditioning system. The resistance of the cooler (room temp. sensor) thermistor changes in accordance with the cabin temperature. As the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases.

The air conditioning amplifier assembly applies voltage (5 V) to the cooler (room temp. sensor) thermistor and reads voltage changes due to changes in the resistance of the cooler (room temp. sensor) thermistor.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1411 |

Room Temperature Sensor Circuit |

Open or short in room temperature sensor circuit |

| Memorized (4 sec. or more)* |

HINT:

If the cabin temperature is approximately -18.6°C (-1.48°F) or lower, DTC B1411 may be stored even though the system is normal.

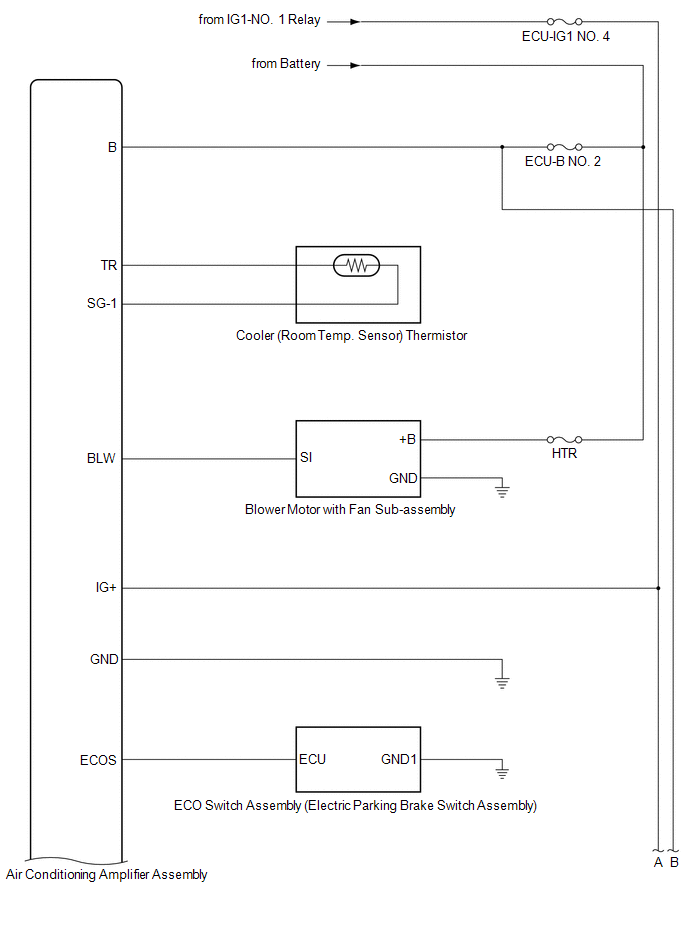

WIRING DIAGRAM

PROCEDURE

| 1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Room Temperature Sensor |

Cooler (room temp. sensor) thermistor |

Min.: -6.50°C (20.30°F) Max.: 57.25°C (135.05°F) |

Actual cabin temperature displayed |

Cooler (room temp. sensor) thermistor circuit malfunction

|

|

Tester Display |

|---|

| Room Temperature Sensor |

OK:

The display is as specified in the normal condition column.

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

| 2. |

INSPECT COOLER (ROOM TEMP. SENSOR) THERMISTOR |

(a) Remove the cooler (room temp. sensor) thermistor.

Click here

(b) Inspect the cooler (room temp. sensor) thermistor.

Click here

| NG |  | REPLACE COOLER (ROOM TEMP. SENSOR) THERMISTOR |

|

| 3. |

CHECK HARNESS AND CONNECTOR (COOLER (ROOM TEMP. SENSOR) THERMISTOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G44-1 - G36-14 (TR) | Always |

Below 1 Ω |

|

G44-2 - G36-1 (SG-1) |

Always | Below 1 Ω |

|

G44-1 or G36-14 (TR) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

G44-2 or G36-1 (SG-1) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

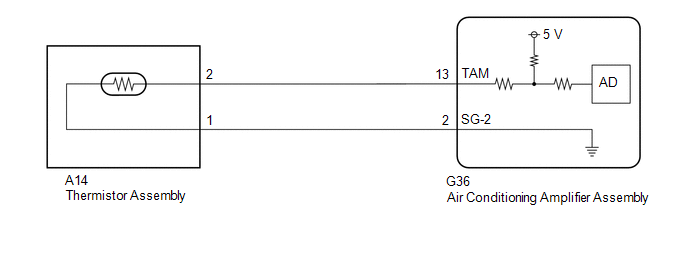

DESCRIPTION

The thermistor assembly is installed in front of the cooler condenser assembly to detect the ambient temperature, which is used to control the air conditioning system. This sensor is connected to the air conditioning amplifier assembly and detects fluctuations in the ambient temperature. This data is used for controlling the cabin temperature. The sensor sends a signal to the air conditioning amplifier assembly. The resistance of the thermistor assembly changes in accordance with the ambient temperature. As the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases.

The air conditioning amplifier assembly applies voltage (5 V) to the thermistor assembly and reads voltage changes due to changes in the resistance of the thermistor assembly.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1412 |

Ambient Temperature Sensor Circuit |

Open or short in ambient temperature sensor circuit |

| Memorized (4 sec. or more)* |

HINT:

If the ambient temperature is approximately -52.9°C (-63.22°F) or lower, DTC B1412 may be stored even though the system is normal.

WIRING DIAGRAM

PROCEDURE

| 1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Ambient Temp Sensor | Thermistor assembly |

Min.: -23.30°C (-9.94°F) Max.: 65.95°C (150.71°F) |

Actual ambient temperature displayed |

Thermistor assembly circuit malfunction

|

|

Tester Display |

|---|

| Ambient Temp Sensor |

OK:

The display is as specified in the normal condition column.

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

| 2. |

INSPECT THERMISTOR ASSEMBLY |

(a) Remove the thermistor assembly.

Click here

(b) Inspect the thermistor assembly.

Click here

| NG |  | REPLACE THERMISTOR ASSEMBLY |

|

| 3. |

CHECK HARNESS AND CONNECTOR (THERMISTOR ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A14-2 - G36-13 (TAM) |

Always | Below 1 Ω |

|

A14-1 - G36-2 (SG-2) |

Always | Below 1 Ω |

|

A14-2 or G36-13 (TAM) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

A14-1 or G36-2 (SG-2) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

The No. 1 cooler thermistor is installed to the evaporator in the air conditioner unit to detect the temperature of the cooled air that has passed through the evaporator, which is used to control the air conditioning system. It sends signals to the air conditioning amplifier assembly. The resistance of the No. 1 cooler thermistor changes in accordance with the temperature of the cooled air that has passed through the evaporator. As the temperature decreases, the resistance increases. As the temperature increases, the resistance decreases.

The air conditioning amplifier assembly applies voltage (5 V) to the No. 1 cooler thermistor and reads voltage changes as the resistance of the No. 1 cooler thermistor changes. This sensor is used for frost prevention.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1413 |

Evaporator Temperature Circuit or Evaporator Fin Thermistor |

Open or short in evaporator temperature sensor circuit |

| Memorized (4 sec. or more)* |

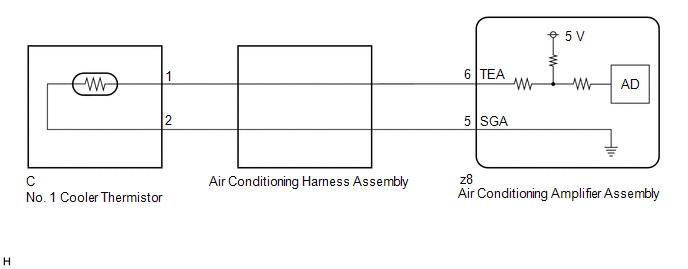

WIRING DIAGRAM

PROCEDURE

| 1. |

READ VALUE USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG)

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Evaporator Fin Thermistor |

No. 1 cooler thermistor |

Min.: -29.70°C (-21.46°F) Max.: 59.55°C (139.19°F) |

Actual evaporator temperature displayed |

No. 1 cooler thermistor circuit malfunction

|

|

Tester Display |

|---|

| Evaporator Fin Thermistor |

OK:

The display is as specified in the normal condition column.

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

| 2. |

INSPECT NO. 1 COOLER THERMISTOR |

(a) Remove the No. 1 cooler thermistor.

Click here

(b) Inspect the No. 1 cooler thermistor.

Click here

| NG |  | REPLACE NO. 1 COOLER THERMISTOR |

|

| 3. |

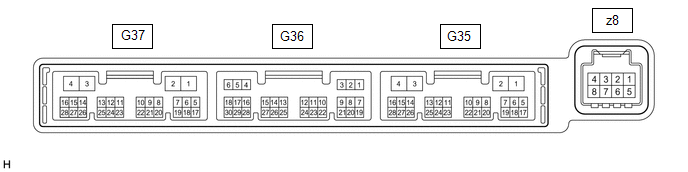

INSPECT AIR CONDITIONING HARNESS ASSEMBLY |

|

*a | Front view of wire harness connector (to Air Conditioning Amplifier Assembly) |

*b | Front view of wire harness connector (to No. 1 Cooler Thermistor) |

(a) Remove the air conditioning harness assembly.

Click here

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

z8-5 (SGA) - C-2 | Always |

Below 1 Ω |

|

z8-6 (TEA) - C-1 | Always |

Below 1 Ω |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

DESCRIPTION

The ECM sends the engine speed signal to the air conditioning amplifier assembly via CAN communication.

The air conditioning amplifier assembly reads the difference between compressor speed and engine speed. If the difference becomes excessively large, the air conditioning amplifier assembly determines that the compressor is locked, and turns the magnet clutch assembly off.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1422 |

Compressor Lock | Open or short in A/C lock sensor circuit |

| Memorized (3 seconds or more) |

HINT:

The air conditioning amplifier assembly stores the DTC if the malfunction has occurred for the period of time indicated in the brackets.

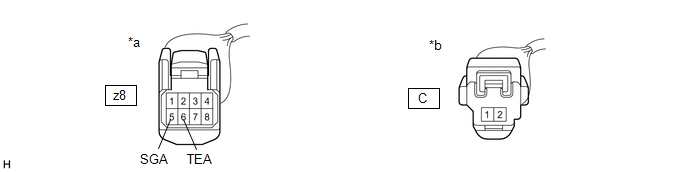

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

Click here

PROCEDURE

|

1. | INSPECT MAGNET CLUTCH ASSEMBLY |

(a) Remove the compressor assembly with magnetic clutch.

Click here

(b) Inspect the magnet clutch assembly.

Click here

| NG |  | REPLACE MAGNET CLUTCH ASSEMBLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (MAGNET CLUTCH ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

C60-1 (SSR+) - G36-21 (LOCK) |

Always | Below 1 Ω |

|

C60-2 (SSR-) - G36-2 (SG-2) |

Always | Below 1 Ω |

|

C60-1 (SSR+) or G36-21 (LOCK) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

C60-2 (SSR-) or G36-2 (SG-2) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

This DTC is stored if refrigerant pressure on the high pressure side is extremely low (176 kPa (1.8 kgf/cm2, 26 psi) or less) or extremely high (3025 kPa (30.8 kgf/cm2, 439 psi) or more). The air conditioner pressure sensor, which is installed to the high pressure side pipe to detect refrigerant pressure, sends a refrigerant pressure signal to the air conditioning amplifier assembly. The air conditioning amplifier assembly converts this signal to a pressure value according to the sensor characteristics and uses it to control the compressor.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1423 |

Open in Pressure Sensor Circuit / Abnormal Refrigerant Pressure |

|

| - |

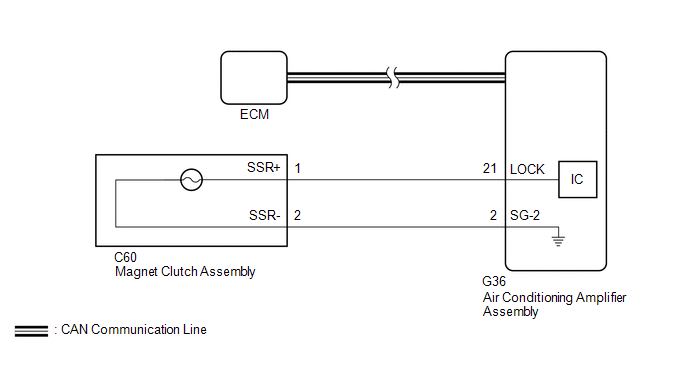

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

If DTC B1423 and B14B8 are output at the same time, troubleshoot for DTC B14B8 first.

Click here

PROCEDURE

| 1. |

PERFORM REFRIGERANT SHORTAGE CHECK |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Utility / Refrigerant Gas Volume Check.

Body Electrical > Air Conditioner > Utility|

Tester Display |

|---|

| Refrigerant Gas Volume Check |

(e) Check that the following conditions are met and perform the refrigerant shortage check according to the display on the Techstream.

Measurement Condition:|

Item | Condition |

|---|---|

|

A/C switch | On |

|

Ambient temperature* |

0 to 49°C (32 to 120°F) |

|

Blower speed | HI |

*: If the ambient temperature is not within the range shown, do not perform this check.

|

Result | Amount of Refrigerant |

|---|---|

|

Refrigerant correct | Correct |

|

Refrigerant shortage |

Insufficient |

OK:

"Refrigerant correct" is displayed on the Techstream.

| NG |  | GO TO STEP 14 |

|

| 2. |

CHECK REFRIGERANT PRESSURE |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

|

Tester Display |

|---|

| Regulator Pressure Sensor |

(f) Install a manifold gauge set.

Click here

(g) Read the manifold gauge set with the following conditions met.

Measurement Condition:|

Item | Condition |

|---|---|

|

Vehicle doors | Fully open |

|

Temperature setting | MAX COLD |

|

Blower speed | HI |

|

A/C switch | On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

25 to 35°C (77 to 95°F) |

Standard Pressure:

Low pressure side

150 to 250 kPa (1.5 to 2.5 kgf/cm2, 22 to 36 psi)

High pressure side

1370 to 1570 kPa (14 to 16 kgf/cm2, 199 to 228 psi)

(h) Compare the values displayed in the Data List and on the manifold gauge set.

OK:

The values displayed in the Data List and on the manifold gauge set match.

| NG |  | GO TO STEP 8 |

|

| 3. |

CHECK REFRIGERANT HIGH PRESSURE HISTORY |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(d) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Refrigerant High Pressure History |

Refrigerant high pressure history |

Min.: 0 Max.: 255 |

Number of times refrigerant high pressure history stored displayed |

- |

|

Tester Display |

|---|

| Refrigerant High Pressure History |

|

Result | Proceed to |

|---|---|

|

The value is 0 | A |

|

The value is not 0 | B |

| A |

| INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET |

|

| 4. |

INSPECT COOLING FAN SYSTEM |

(a) Check if the cooling fan operates normally.

Click here

| NG |  | GO TO COOLING FAN SYSTEM |

|

| 5. |

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM |

(a) Recover the refrigerant from the air conditioning system using a refrigerant recovery unit.

Click here

|

| 6. |

CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

Click here

|

| 7. |

PERFORM REFRIGERANT HIGH PRESSURE HISTORY CLEAR |

(a) Clear the refrigerant high pressure history stored in the air conditioning amplifier assembly.

Click here

| NEXT |  | END |

| 8. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

|

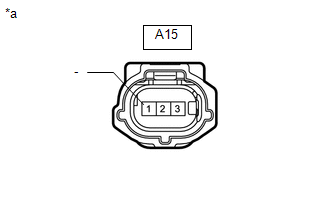

*a | Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Disconnect the A15 air conditioner pressure sensor connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-3 (+) - A15-1 (-) |

Engine switch on (IG) |

4.75 to 5.25 V |

| NG |  | GO TO STEP 13 |

|

| 9. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - BODY GROUND) |

|

*a | Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-1 (-) - Body ground |

Always | Below 1 Ω |

| NG |  | GO TO STEP 12 |

|

| 10. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-2 (PR) - G36-24 (PRE) |

Always | Below 1 Ω |

|

A15-2 (PR) or G36-24 (PRE) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11. |

INSPECT AIR CONDITIONER PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT) |

|

*a | Component with harness connected (Air Conditioning Amplifier Assembly) |

(a) Measure the voltage with the following conditions met.

Measurement Condition:|

Item | Condition |

|---|---|

|

Vehicle doors | Fully open |

|

Temperature setting | MAX COLD |

|

Blower speed | HI |

|

A/C switch | On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

25 to 35°C (77 to 95°F) |

NOTICE:

HINT:

When the ambient air temperature is low(below -1.5°C (29.3°F)), the compressor with pulley will be stopped, due to inputs of the thermistor assembly and No. 1 cooler thermistor, to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

(1) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G36-24 (PRE) - Body ground |

Engine switch on (IG) (A/C switch: On) |

0.74 to 4.61 V |

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(f) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

|

Tester Display |

|---|

| Regulator Pressure Sensor |

OK:

The voltage and value displayed in the Data List change.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (The voltage changes but the value displayed in the Data List does not change.) | |

|

NG (The voltage does not change.) |

B |

| A |

| REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| B |

| REPLACE AIR CONDITIONER PRESSURE SENSOR |

| 12. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-1 (-) - G36-3 (SG-4) |

Always | Below 1 Ω |

|

A15-1 (-) or G36-3 (SG-4) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 13. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G36 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A15-3 (+) - G36-6 (S5-3) |

Always | Below 1 Ω |

|

A15-3 (+) or G36-6 (S5-3) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 14. |

REPAIR AIR CONDITIONING SYSTEM LEAK |

(a) Identify the area where refrigerant is leaking from.

Click here

(b) Repair the identified area of the air conditioning system.

(c) Evacuate the air conditioning system.

| NEXT |  | CHARGE SYSTEM WITH REFRIGERANT |

DESCRIPTION

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1441 |

Air Mix Damper Control Servo Motor Circuit (Passenger Side) |

Air mix damper position sensor value does not change even if air conditioning amplifier assembly operates No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) |

| Memorized (30 sec. or more)* |

|

B1443 | Air Outlet Damper Control Servo Motor Circuit |

Air outlet damper position sensor value does not change even if air conditioning amplifier assembly operates No. 1 air conditioning radiator damper servo sub-assembly (mode) |

| Memorized (30 sec. or more)* |

|

B1446 | Air Mix Damper Control Servo Motor Circuit (Driver Side) |

Air mix damper position sensor value does not change even if air conditioning amplifier assembly operates No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) |

| Memorized (30 sec. or more)* |

|

Vehicle Condition | |||

|---|---|---|---|

|

Pattern 1 | Pattern 2 | ||

|

Diagnosis Condition | No. 1 air conditioning radiator damper servo sub-assembly operating |

○ | ○ |

|

Malfunction | Damper servo operation request signals are output but the damper position sensor value does not change |

○ | - |

|

Damper servo operation request signals are output but the damper position sensor value is abnormal |

- | ○ | |

|

Detection Time | Continuously for 30 seconds or more |

Continuously for 30 seconds or more | |

|

Trip Count | 1 trip |

1 trip | |

HINT:

If the conditions of either of these patterns are detected, a DTC will be stored.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Click here

Click here

PROCEDURE

|

1. | CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

Only B1497 is output |

A |

| B1441, B1442, B1443 and B1446 are output |

B |

| B1441, B1443 or B1446 is output |

C |

| A |

| GO TO DTC B1497 |

| B |

| REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

|

| 2. |

INSPECT NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY (INSTALLATION CONDITION) |

(a) Check that the No. 1 air conditioning radiator damper servo sub-assembly is installed correctly.

OK:

The No. 1 air conditioning radiator damper servo sub-assembly is installed correctly.

| NG |  | INSTALL NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY CORRECTLY |

|

| 3. |

INSPECT NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY (MOTOR, LINK, DAMPER) |

(a) Check for a wire harness caught between the links of the motors and dampers.

OK:

No wire harnesses are caught between the links of the motors and dampers.

| NG |  | REMOVE PINCHED WIRE HARNESS |

|

| 4. |

INSPECT AIR CONDITIONING RADIATOR ASSEMBLY (DAMPER) |

(a) Remove the No. 1 air conditioning radiator damper servo sub-assembly.

Click here

(b) Operate the dampers by hand.

OK:

The dampers are easily operated by hand.

| OK |  | REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

| NG |  | REPLACE AIR CONDITIONING RADIATOR ASSEMBLY |

DESCRIPTION

The No. 1 blower damper servo sub-assembly sends pulse signals to inform the air conditioning amplifier assembly of the damper position. The air conditioning amplifier assembly activates the motor (normal or reverse) based on these signals to move the air inlet damper to the appropriate position to change the air inlet mode (fresh, recirculation/fresh, and recirculation).

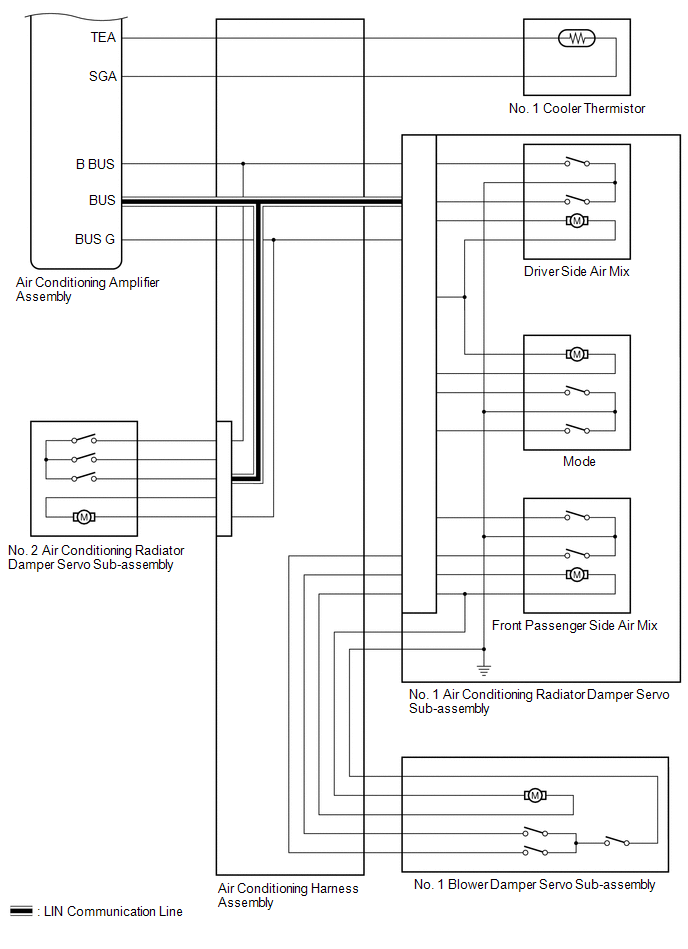

The air conditioning amplifier assembly communicates with the servo through a communication/driver IC and wiring assembly called the air conditioning harness assembly.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1442 |

Air Inlet Damper Control Servo Motor |

Air inlet damper position sensor value does not change even if air conditioning amplifier assembly operates No. 1 blower damper servo sub-assembly |

| Memorized (30 sec. or more)* |

|

Vehicle Condition | |||

|---|---|---|---|

|

Pattern 1 | Pattern 2 | ||

|

Diagnosis Condition | No. 1 blower damper servo sub-assembly operating |

○ | ○ |

|

Malfunction | Air inlet damper servo operation request signals are output but the air inlet damper position sensor value does not change |

○ | - |

|

Air inlet damper servo operation request signals are output but the air inlet damper position sensor value is abnormal |

- | ○ | |

|

Detection Time | Continuously for 30 seconds or more |

Continuously for 30 seconds or more | |

|

Trip Count | 1 trip |

1 trip | |

HINT:

If the conditions of either of these patterns are detected, a DTC will be stored.

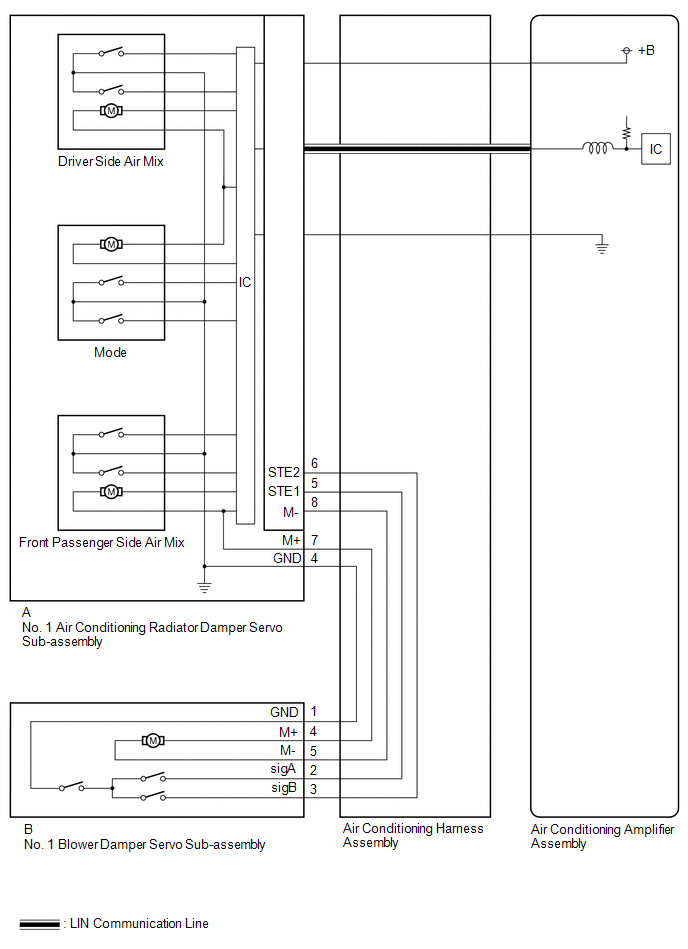

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Click here

Click here

PROCEDURE

|

1. | CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

Only B1497 is output |

A |

| B1441, B1442, B1443 and B1446 are output |

B |

| Only B1442 is output |

C |

| A |

| GO TO DTC B1497 |

| B |

| REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

|

| 2. |

INSPECT NO. 1 BLOWER DAMPER SERVO SUB-ASSEMBLY (INSTALLATION CONDITION) |

(a) Check that the No. 1 blower damper servo sub-assembly is installed correctly.

OK:

The No. 1 blower damper servo sub-assembly is installed correctly.

| NG |  | INSTALL NO. 1 BLOWER DAMPER SERVO SUB-ASSEMBLY |

|

| 3. |

INSPECT NO. 1 BLOWER DAMPER SERVO SUB-ASSEMBLY (MOTOR, LINK, DAMPER) |

(a) Check for a wire harness caught between the links of the motors and dampers.

OK:

No wire harnesses are caught between the links of the motors and dampers.

| NG |  | REMOVE PINCHED WIRE HARNESS |

|

| 4. |

INSPECT NO. 1 BLOWER DAMPER SERVO SUB-ASSEMBLY (DAMPER) |

(a) Remove the No. 1 blower damper servo sub-assembly.

Click here

(b) Operate the air inlet dampers by hand.

OK:

The air inlet dampers are easily operated by hand.

| NG |  | REPLACE BLOWER ASSEMBLY |

|

| 5. |

INSPECT AIR CONDITIONING HARNESS ASSEMBLY |

(a) Disconnect the No. 1 air conditioning radiator damper servo sub-assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A-6 (STE2) - B-3 (sigB) |

Always | Below 1 Ω |

|

A-5 (STE1) - B-2 (sigA) |

Always | Below 1 Ω |

|

A-8 (M-) - B-5 (M-) | Always |

Below 1 Ω |

|

A-7 (M+) - B-4 (M+) | Always |

Below 1 Ω |

|

A-4 (GND) - B-1 (GND) |

Always | Below 1 Ω |

|

A-6 (STE2) or B-3 (sigB) - Other terminals and Body ground |

Always | 10 kΩ or higher |

|

A-5 (STE1) or B-2 (sigA) - Other terminals and Body ground |

Always | 10 kΩ or higher |

|

A-8 (M-) or B-5 (M-) - Other terminals and Body ground |

Always | 10 kΩ or higher |

|

A-7 (M+) or B-4 (M+) - Other terminals and Body ground |

Always | 10 kΩ or higher |

| NG |  | REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

|

| 6. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the No. 1 air conditioning radiator damper servo sub-assembly connector.

(b) Remove the No. 2 air conditioning radiator damper servo sub-assembly.

Click here

(c) Connect the No. 1 blower damper servo sub-assembly connector to the No. 2 air conditioning radiator damper servo sub-assembly.

(d) Connect the Techstream to the DLC3.

(e) Turn the engine switch on (IG).

(f) Turn the Techstream on.

(g) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(h) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Inlet Damper Targ Pulse |

No. 1 blower damper servo sub-assembly pulse* |

Min.: 128 Max.: 383 |

Operates between 220 and 256 pulses |

|

Tester Display |

|---|

| Air Inlet Damper Targ Pulse |

OK:

The No. 2 air conditioning radiator damper servo sub-assembly operates.

| OK |  | REPLACE NO. 1 BLOWER DAMPER SERVO SUB-ASSEMBLY |

| NG |  | REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

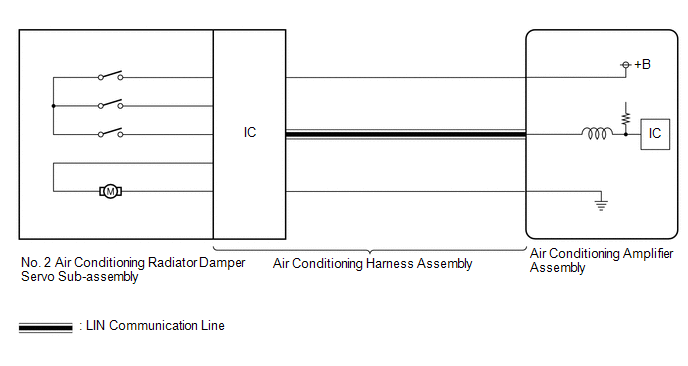

DESCRIPTION

The No. 2 air conditioning radiator damper servo sub-assembly sends pulse signals to inform the air conditioning amplifier assembly of the damper position. The air conditioning amplifier assembly activates the motor (normal or reverse) based on these signals to move the air outlet damper to the appropriate position, which controls the rear air outlet switching. The air conditioning amplifier assembly communicates with the servo through a communication/driver IC and wiring assembly called the air conditioning harness assembly.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1449 |

Air Outlet Damper Control Servo Motor Circuit (Rear) |

Air outlet damper position sensor value does not change even if air conditioning amplifier assembly operates No. 2 air conditioning radiator damper servo sub-assembly |

| Memorized (30 sec. or more)* |

|

Vehicle Condition | |||

|---|---|---|---|

|

Pattern 1 | Pattern 2 | ||

|

Diagnosis Condition | No. 2 air conditioning radiator damper servo sub-assembly operating |

○ | ○ |

|

Malfunction | Air outlet damper servo operation request signals are output but the rear passenger side air outlet damper position sensor value does not change |

○ | - |

|

Air outlet damper servo operation request signals are output but the rear passenger side air outlet damper position sensor value is abnormal |

- | ○ | |

|

Detection Time | Continuously for 30 seconds or more |

Continuously for 30 seconds or more | |

|

Trip Count | 1 trip |

1 trip | |

HINT:

If the conditions of either of these patterns are detected, a DTC will be stored.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Click here

Click here

PROCEDURE

|

1. | CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Air Conditioner > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTC B1497 is not output |

A |

| DTC B1497 is output |

B |

| B |

| GO TO DTC B1497 |

|

| 2. |

INSPECT NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY (INSTALLATION CONDITION) |

(a) Check that the No. 2 air conditioning radiator damper servo sub-assembly is installed correctly.

Click here

OK:

The No. 2 air conditioning radiator damper servo sub-assembly is installed correctly.

| NG |  | INSTALL NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY CORRECTLY |

|

| 3. |

INSPECT NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY (MOTOR, LINK, DAMPER) |

(a) Check for a wire harness caught between the links of the motors and dampers.

OK:

No wire harnesses are caught between the links of the motors and dampers.

| NG |  | REMOVE PINCHED WIRE HARNESS |

|

| 4. |

INSPECT AIR CONDITIONING RADIATOR ASSEMBLY (DAMPER) |

(a) Remove the No. 2 air conditioning radiator damper servo sub-assembly.

Click here

(b) Operate the dampers by hand.

OK:

The dampers are easily operated by hand.

| NG |  | REPLACE AIR CONDITIONING RADIATOR ASSEMBLY |

|

| 5. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Remove the No. 1 air conditioning radiator damper servo sub-assembly.

Click here

(b) Connect the No. 1 air conditioning radiator damper servo sub-assembly connector to the No. 2 air conditioning radiator damper servo sub-assembly.

(c) Connect the Techstream to the DLC3.

(d) Turn the engine switch on (IG).

(e) Turn the Techstream on.

(f) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(g) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Outlet Servo Pulse (D) |

No. 1 air conditioning radiator damper servo sub-assembly (mode) pulse* |

Min.: 128 Max.: 383 |

Operates between 241 and 348 pulses |

|

Tester Display |

|---|

| Air Outlet Servo Pulse (D) |

OK:

The No. 2 air conditioning radiator damper servo sub-assembly operates.

| OK |  | REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

| NG |  | REPLACE NO. 2 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

DESCRIPTION

The cooler compressor assembly receives refrigerant compression demand signals from the air conditioning amplifier assembly.

Based on this signal, the cooler compressor assembly changes the amount of compressor output.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1451 |

Compressor Solenoid Circuit |

Open or short in compressor solenoid circuit |

| - |

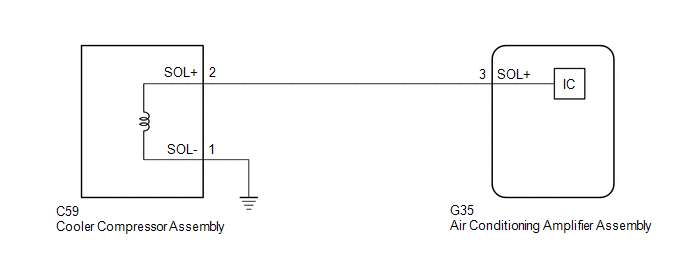

WIRING DIAGRAM

PROCEDURE

| 1. |

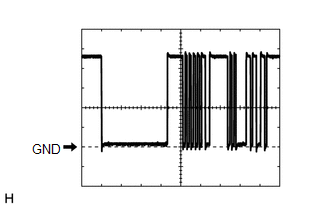

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

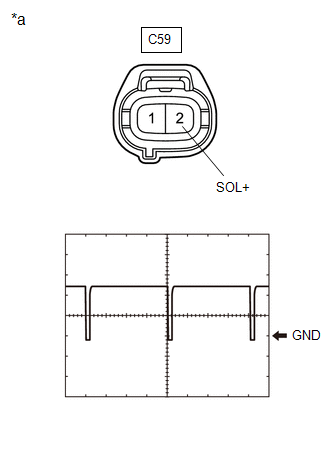

|

*a | Front view of wire harness connector (to Cooler Compressor Assembly) |

(a) Disconnect the C59 cooler compressor assembly connector.

(b) Connect an oscilloscope to terminal C59-2 (SOL+) and body ground and check the waveform.

|

Item | Content |

|---|---|

|

Tool Setting | 5 V/DIV., 500 μs./DIV. |

|

Condition |

|

OK:

Waveform is similar to that shown in the illustration.

| OK |  | REPLACE COOLER COMPRESSOR ASSEMBLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (COOLER COMPRESSOR ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G35 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

C59-2 (SOL+) - G35-3 (SOL+) |

Always | Below 1 Ω |

|

C59-2 (SOL+) or G35-3 (SOL+) - Other terminals and body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

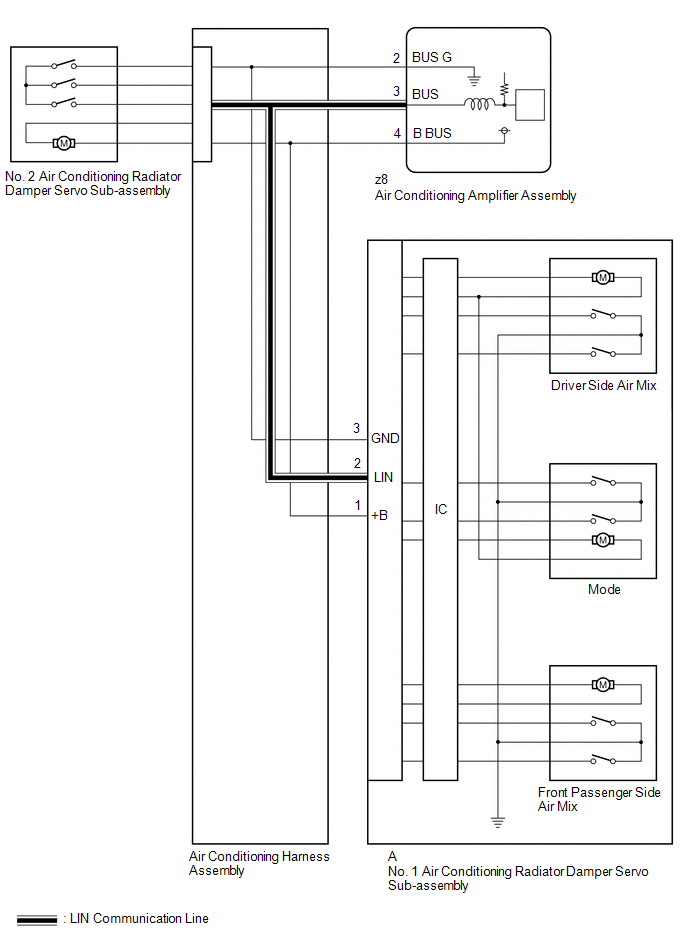

DESCRIPTION

The air conditioning harness assembly connects the air conditioning amplifier assembly and the servo motors. The air conditioning amplifier assembly supplies power and sends operation instructions to each servo motor through the air conditioning harness assembly. Each servo motor sends damper position information to the air conditioning amplifier assembly.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Memory |

|---|---|---|---|---|

| B1497 |

Communication Malfunction (Bus Ic) |

Error or open in communication line |

| Memorized (10 sec. or more)* |

WIRING DIAGRAM

PROCEDURE

| 1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 and 257 pulses |

|

A/O Servo Pulse(Rr D) | No. 2 air conditioning radiator damper servo sub-assembly pulse |

Min.: 128 Max.: 383 |

Operates between 158 and 260 pulses |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(D) |

|

Tester Display |

|---|

| A/O Servo Pulse(Rr D) |

|

Result | Proceed to |

|---|---|

|

All of the damper servo motors are malfunctioning |

A |

| One of the damper servo motors is malfunctioning |

B |

| B |

| GO TO STEP 4 |

|

| 2. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Disconnect the No. 1 air conditioning radiator damper servo sub-assembly connector.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Air Conditioner / Active test.

(f) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

A/O Servo Pulse(Rr D) | No. 2 air conditioning radiator damper servo sub-assembly pulse |

Min.: 128 Max.: 383 |

Operates between 158 and 260 pulses |

|

Tester Display |

|---|

| A/O Servo Pulse(Rr D) |

OK:

The damper servo motor operates smoothly.

| OK |  | REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

|

| 3. |

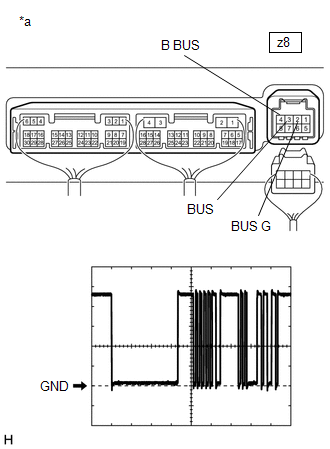

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

*a | Component with harness connected (Air Conditioning Amplifier Assembly) |

NOTICE:

When inspecting the air conditioning amplifier assembly, do not bring the tester probes too close to each other as a short circuit may occur.

(a) Disconnect the z8 air conditioning amplifier assembly connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

z8-4 (B BUS) - Body ground |

Engine switch on (IG) |

11 to 14 V |

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

z8-2 (BUS G) - Body ground |

Always | Below 1 Ω |

(c) Turn the engine switch on (IG).

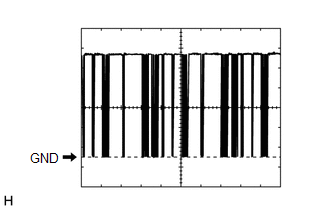

(d) Using an oscilloscope, check the waveform.

|

Item | Content |

|---|---|

|

Terminal No. | z8-3 (BUS) - z8-2 (BUS G) |

|

Tool Setting | 2 V/DIV., 2 ms./DIV. |

|

Condition | Engine switch on (IG) |

OK:

Waveform is similar to that shown in the illustration.

HINT:

The waveform varies with the blower speed.

| OK |  | REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

| NG |  | REPLACE AIR CONDITIONING AMPLIFIER ASSEMBLY |

| 4. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 and 257 pulses |

|

A/O Servo Pulse(Rr D) | No. 2 air conditioning radiator damper servo sub-assembly pulse |

Min.: 128 Max.: 383 |

Operates between 158 and 260 pulses |

|

Tester Display |

|---|

| Air Mix Servo Targ Pulse(D) |

|

Tester Display |

|---|

| A/O Servo Pulse(Rr D) |

|

Result | Proceed to |

|---|---|

|

Only the No. 1 air conditioning radiator damper servo sub-assembly does not operate |

A |

| Only the No. 2 air conditioning radiator damper servo sub-assembly does not operate |

B |

| B |

| REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

|

| 5. |

INSPECT AIR CONDITIONING HARNESS ASSEMBLY (AIR CONDITIONING AMPLIFIER ASSEMBLY - NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY) |

(a) Disconnect the z8 air conditioning amplifier assembly connector.

(b) Disconnect the No. 1 air conditioning radiator damper servo sub-assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

z8-2 (BUS G) - A-3 (GND) |

Always | Below 1 Ω |

|

z8-3 (BUS) - A-2 (LIN) |

Always | Below 1 Ω |

|

z8-4 (B BUS) - A-1 (+B) |

Always | Below 1 Ω |

| OK |  | REPLACE NO. 1 AIR CONDITIONING RADIATOR DAMPER SERVO SUB-ASSEMBLY |

| NG |  | REPLACE AIR CONDITIONING HARNESS ASSEMBLY |

DESCRIPTION

The blower motor with fan sub-assembly is operated by signals from the air conditioning amplifier assembly. Blower motor speed signals are transmitted in accordance with changes in the duty ratio.

If the airflow volume is low or the blower speed cannot be changed, the following factors may be the cause.

|

Symptom | Factor |

|---|---|

|

Airflow volume cannot be changed |

|

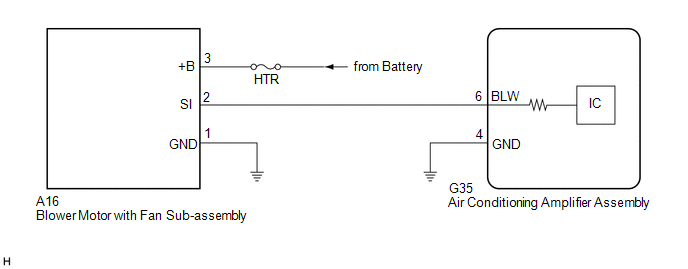

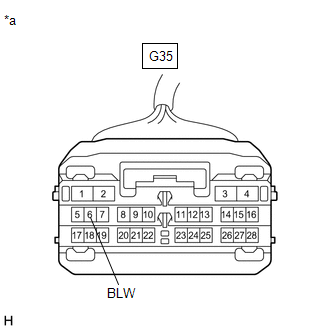

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

| 1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Blower Motor | Blower motor with fan sub-assembly |

Min.: 0 Max.: 31 |

- |

|

Tester Display |

|---|

| Blower Motor |

| Result |

Proceed to |

|---|---|

| Blower motor with fan sub-assembly does not operate |

A |

| Blower motor with fan sub-assembly operates but does not change speed |

B |

| B |

| GO TO STEP 5 |

|

| 2. |

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR WITH FAN SUB-ASSEMBLY - POWER SOURCE AND BODY GROUND) |

(a) Disconnect the A16 blower motor with fan sub-assembly connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A16-3 (+B) - Body ground |

Always | 11 to 14 V |

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A16-1 (GND) - Body ground |

Always | Below 1 Ω |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR WITH FAN SUB-ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the G35 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|