DESCRIPTION

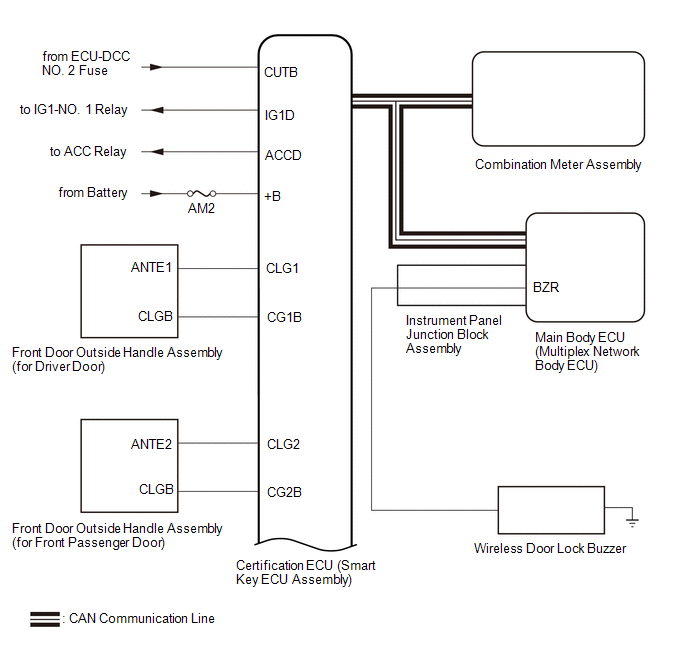

If the entry lock and wireless door lock operations cannot be performed, the electrical key and tire pressure monitoring system receiver assembly may be malfunctioning, or there may be wave interference or problems in the communication which is used for the entry and wireless function between the electrical key and tire pressure monitoring system receiver assembly and certification ECU (smart key ECU assembly).

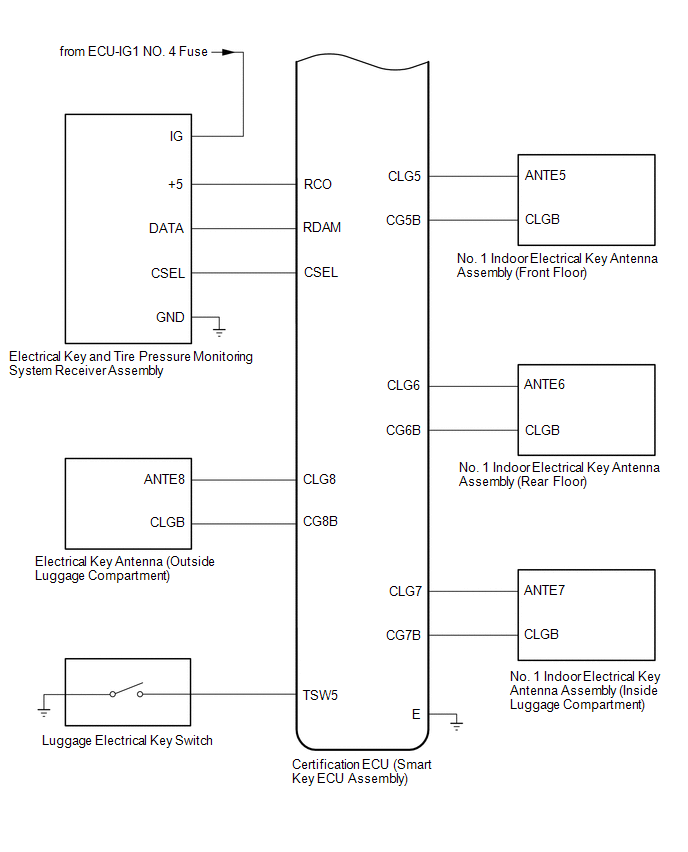

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

Click here

Click here

) after registration (Click here

) after registration (Click here

) of the transmitter IDs into the electrical key and tire pressure

monitoring system receiver assembly if the electrical key and tire

pressure monitoring system receiver assembly has been replaced.

) of the transmitter IDs into the electrical key and tire pressure

monitoring system receiver assembly if the electrical key and tire

pressure monitoring system receiver assembly has been replaced.

PROCEDURE

|

1. | INSPECT BATTERY VOLTAGE |

(a) Measure the battery voltage.

Standard Voltage:

11 to 14 V

HINT:

It may be possible to tell whether the battery is discharged by operating the horn.

If the voltage is below 11 V, recharge or replace the battery before proceeding to the next step.

|

| 2. |

CHECK FOR DTC |

(a) Open the driver door using the mechanical key built into the electrical key transmitter sub-assembly.

(b) Check for DTCs.

Body Electrical > Smart Key > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTCs are not output | A |

|

DTCs are output | B |

| B |

| GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

| 3. |

CHECK DOOR AJAR WARNING |

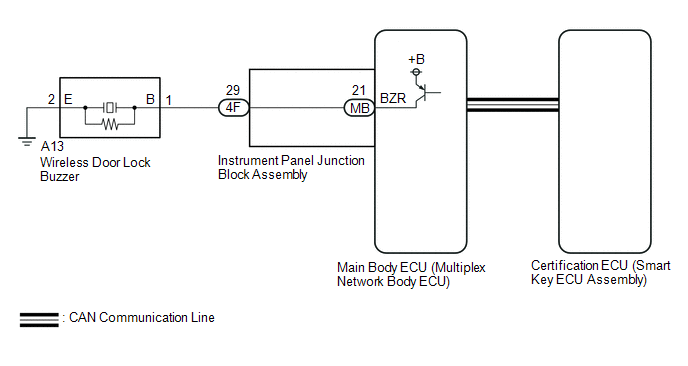

(a) When the doors are locked by operating the entry lock function with all doors closed, check that the door ajar warning operates.

HINT:

Be sure to check the following before performing the procedure.

|

Result | Proceed to |

|---|---|

|

The wireless buzzer does not sound |

A |

| The wireless buzzer sounds |

B |

| B |

| GO TO LIGHTING SYSTEM (Proceed to Door Courtesy Switch Circuit) |

|

| 4. |

CHECK POWER DOOR LOCK CONTROL SYSTEM |

(a) When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation.

Click here

|

Result | Proceed to |

|---|---|

|

Power door lock function operates normally |

A |

| Power door lock function does not operate normally |

B |

| B |

| GO TO POWER DOOR LOCK CONTROL SYSTEM |

|

| 5. |

CHECK KEY DIAGNOSTIC MODE |

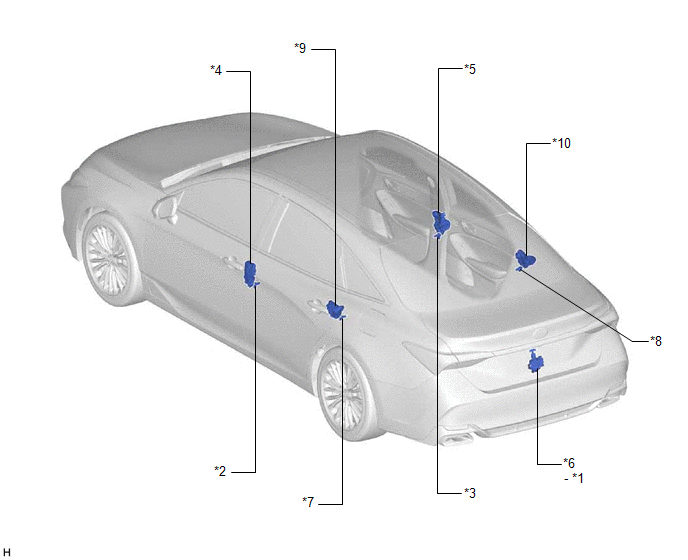

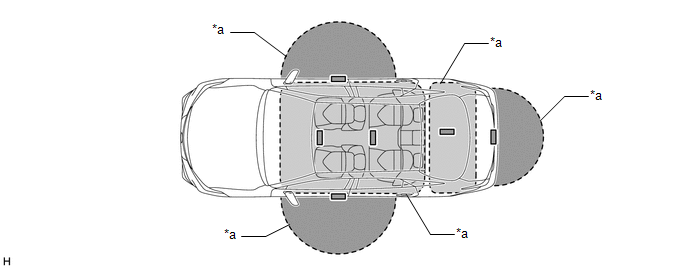

(a) Check the following antennas in key diagnostic mode.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

| (1) Check the electrical key antenna (for driver door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly (for driver door), check that the wireless buzzer sounds. HINT:

|

|

| (2) Check the electrical key antenna (for front passenger door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly (for front passenger door), check that the wireless buzzer sounds. HINT:

|

|

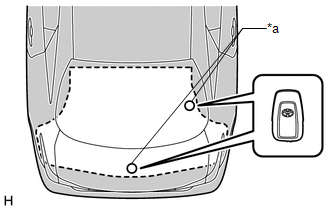

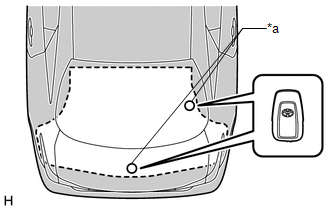

| (3) Check the No. 1 indoor electrical key antenna assembly (front floor): When the electrical key transmitter sub-assembly is at either inspection point, check that the wireless buzzer sounds. HINT:

|

|

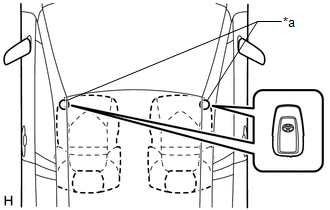

| (4) Check the No. 1 indoor electrical key antenna assembly (rear floor): When the electrical key transmitter sub-assembly is at either inspection point, check that the wireless buzzer sounds. HINT:

|

|

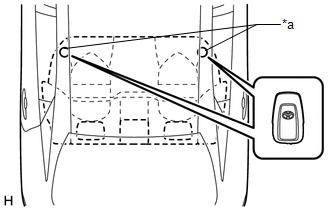

| (5) Check the No. 1 indoor electrical key antenna assembly (inside luggage compartment): When the electrical key transmitter sub-assembly is at either inspection point, check that the wireless buzzer sounds. HINT:

|

|

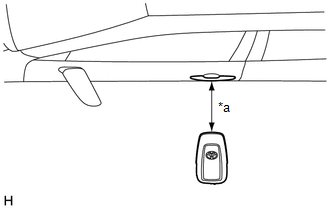

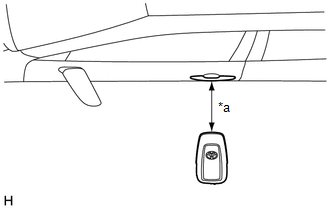

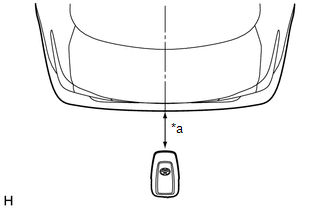

| (6) Check the electrical key antenna (outside luggage compartment): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the electrical key antenna (outside luggage compartment), check that the wireless buzzer sounds. HINT:

OK: Wireless buzzer sounds. |

|

|

Result | Proceed to |

|---|---|

|

Key diagnostic mode inspections fail for both channels |

A |

| Key diagnostic mode inspections succeed for both channels |

B |

| Key diagnostic mode inspection succeeds for only one of the channels |

C |

| B |

| GO TO STEP 18 |

| C |

| GO TO STEP 28 |

|

| 6. |

CHECK WAVE ENVIRONMENT |

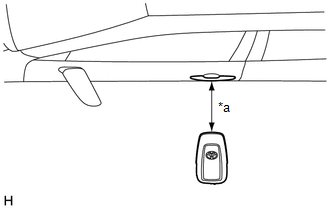

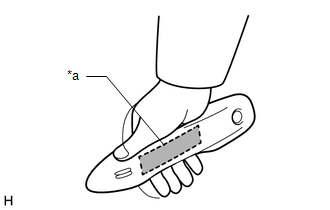

(a) Bring the electrical key transmitter sub-assembly near the electrical key and tire pressure monitoring system receiver assembly and perform a wireless operation 2 or more times*.

HINT:

|

Result | Proceed to |

|---|---|

|

Wireless function does not operate normally |

A |

| Wireless function operates normally |

B |

| B |

| AFFECTED BY WAVE INTERFERENCE |

|

| 7. |

CHECK TRANSMITTER BATTERY |

(a) Check the transmitter battery level of the electrical key transmitter sub-assembly that was checked first.

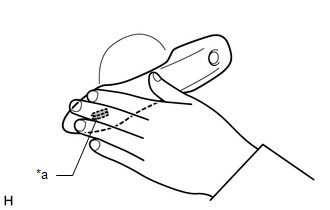

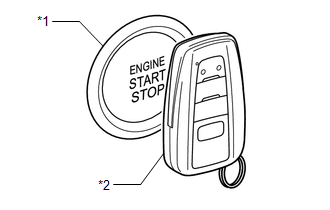

(1) Press and hold the lock switch of the electrical key transmitter sub-assembly for 5 seconds and check the number of times that the LED illuminates.

HINT:

Click here

|

Result | Proceed to |

|---|---|

|

LED illuminates 3 times or more when switch is pressed and held |

A |

| LED does not illuminate when switch is pressed and held |

B |

| LED illuminates once or twice but not a third time |

C |

| B |

| GO TO STEP 17 |

| C |

| REPLACE TRANSMITTER BATTERY |

|

| 8. |

CHECK ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

(a) Check if there is another electrical key transmitter sub-assembly available that is already registered to the vehicle.

|

Result | Proceed to |

|---|---|

|

Another registered electrical key transmitter sub-assembly is not available |

A |

| Another registered electrical key transmitter sub-assembly is available |

B |

| B |

| GO TO STEP 10 |

|

| 9. |

ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY REGISTRATION (NEW ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY) |

(a) Register a new electrical key transmitter sub-assembly.

Click here

|

| 10. |

CHECK ENTRY LOCK OPERATION |

(a) Using another registered electrical key transmitter sub-assembly, check that the function operates normally.

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY WAS DEFECTIVE) |

|

| 11. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER AND BODY GROUND) |

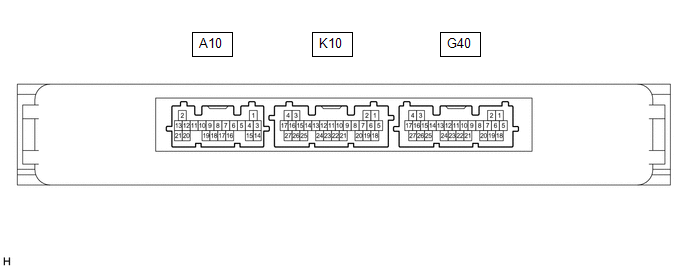

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the K11 electrical key and tire pressure monitoring system receiver assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-18 (RCO) - K11-8 (+5) |

Always | Below 1 Ω |

|

K10-19 (RDAM) - K11-2 (DATA) |

Always | Below 1 Ω |

|

K10-20 (CSEL) - K11-6 (CSEL) |

Always | Below 1 Ω |

|

K11-12 (GND) - Body ground |

Always | Below 1 Ω |

|

K10-18 (RCO) or K11-8 (+5) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

K10-19 (RDAM) or K11-2 (DATA) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

K10-20 (CSEL) or K11-6 (CSEL) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 12. |

CHECK ENTRY LOCK OPERATION |

(a) Connect all connectors and check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 13. |

CHECK ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER ASSEMBLY |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-12 (GND) - Body ground |

Always | Below 1 Ω |

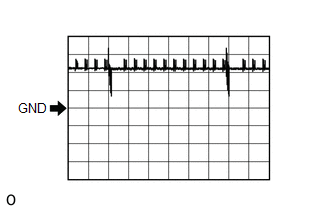

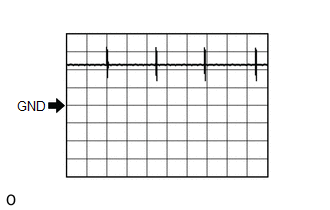

| (b) Using an oscilloscope, check the waveform. OK:

|

|

| NG |  | REPLACE ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER ASSEMBLY |

|

| 14. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| (b) Using an oscilloscope, check the waveform. OK:

|

|

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 15. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) and perform registration again.

HINT:

Click here

Click here

|

| 16. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the wireless function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

| END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| 17. |

INSPECT TRANSMITTER BATTERY |

(a) Inspect the transmitter battery.

Click here

NOTICE:

Do not wrap the lead wire around a terminal, wedge it between terminals, or solder it. The terminal may be deformed or damaged, and the transmitter battery will not be able to be installed correctly.

| OK |  | REPLACE ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

| NG |  | REPLACE TRANSMITTER BATTERY |

| 18. |

PERFORM REGISTRATION |

(a) Perform registration of the B code.

Click here

|

| 19. |

CHECK ENTRY LOCK OPERATION |

(a) After completing B code registration, check that the entry lock and unlock functions can be operated 2 times consecutively.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (B CODE REGISTRATION FAILED) |

|

| 20. |

READ VALUE USING TECHSTREAM (B CODE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Smart Key > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

B Code | B code registration status |

No Regd or Regd | No Regd: B code not registered correctly Regd: B code registered correctly |

- |

|

Tester Display |

|---|

| B Code |

|

Result | Proceed to |

|---|---|

|

"No Regd" is displayed on the Techstream |

A |

| "Regd" is displayed on the Techstream |

B |

| B |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 21. |

READ VALUE USING TECHSTREAM (B CODE DIFFERENCE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Smart Key > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

B Code Difference | B code mismatch |

No or Yes | No: Communication normal Yes: Communication malfunction |

- |

|

Tester Display |

|---|

| B Code Difference |

|

Result | Proceed to |

|---|---|

|

"No" is displayed on the Techstream |

A |

| "Yes" is displayed on the Techstream |

B |

| B |

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 22. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Measure the voltage while checking the Data List on the Techstream.

(1) Connect the Techstream to the DLC3.

(2) Turn the engine switch on (IG).

(3) Turn the Techstream on.

(4) Enter the following menus: Body Electrical / Power Source Control / Data List.

(5) Read the Data List according to the display on the Techstream.

|

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

- | - |

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Power Supply Condition |

Power supply state | All OFF, ACC ON, IG ON or ST ON |

All OFF: Engine switch off ACC ON: Engine switch on (ACC) IG ON: Engine switch on (IG) ST ON: Sending engine start request signal |

- |

|

Tester Display |

|---|

| Power Supply Condition |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G40-17 (IG1D) - Body ground |

Engine switch off | Below 1 V |

|

Engine switch on (ACC) |

Below 1 V | |

|

Engine switch on (IG) |

9 V or higher | |

|

G40-16 (ACCD) - Body ground |

Engine switch off | Below 1 V |

|

Engine switch on (ACC) |

9 V or higher | |

|

Engine switch on (IG) |

9 V or higher |

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 23. |

READ VALUE USING TECHSTREAM (ACC SW, IG SW) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Main Body > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ACC SW | Engine switch status |

OFF or ON | OFF: Engine switch off ON: Engine switch on (ACC) |

"ON" is also displayed when the engine switch is on (IG). |

|

IG SW | Engine switch status |

OFF or ON | OFF: Engine switch off ON: Engine switch on (IG) |

"OFF" is also displayed when the engine switch is on (ACC). |

|

Tester Display |

|---|

| ACC SW |

|

IG SW |

HINT:

If the certification ECU (smart key ECU assembly) misjudges for any reason that the engine switch is on (IG) even though the engine switch is off, the entry lock and unlock functions will be disabled.

|

Result | Proceed to |

|---|---|

|

The main body ECU (multiplex network body ECU) judges properly that the power source is off when the engine switch is off |

A |

| The main body ECU (multiplex network body ECU) does not judge properly that the power source is off when the engine switch is off |

B |

| B |

| TROUBLESHOOT MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

| 24. |

CHECK HARNESS AND CONNECTOR (BODY GROUND, POWER SUPPLY) |

| (a) Disconnect the G40 certification ECU (smart key ECU assembly) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G40-18 (E) - Body ground |

Always | Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

G40-15 (CUTB) - Body ground |

Always | 11 to 14 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 25. |

CHECK ENTRY LOCK OPERATION |

(a) Disconnect and reconnect the certification ECU (smart key ECU assembly) connectors.

(b) Check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 26. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) with a new one and perform registration again.

HINT:

Click here

Click here

|

| 27. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

| END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| 28. |

CHECK WAVE ENVIRONMENT |

(a) Bring the electrical key transmitter sub-assembly near the electrical key and tire pressure monitoring system receiver assembly and perform a wireless operation 2 or more times*.

HINT:

|

Result | Proceed to |

|---|---|

|

Wireless function does not operate normally |

A |

| Wireless function operates normally 1 or more times. |

B |

| B |

| AFFECTED BY WAVE INTERFERENCE |

|

| 29. |

CHECK ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

(a) Check if there is another electrical key transmitter sub-assembly available that is already registered to the vehicle.

|

Result | Proceed to |

|---|---|

|

Another registered electrical key transmitter sub-assembly is not available |

A |

| Another registered electrical key transmitter sub-assembly is available |

B |

| B |

| GO TO STEP 31 |

|

| 30. |

ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY REGISTRATION (NEW ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY) |

(a) Register a new electrical key transmitter sub-assembly.

Click here

|

| 31. |

CHECK WAVE ENVIRONMENT |

(a) Bring another registered electrical key transmitter sub-assembly near the electrical key and tire pressure monitoring system receiver assembly and perform a wireless operation 2 or more times*.

HINT:

|

Result | Proceed to |

|---|---|

|

Wireless function does not operate normally |

A |

| Wireless function operates normally 1 or more times. |

B |

| B |

| END (ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY WAS DEFECTIVE) |

|

| 32. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER ASSEMBLY) |

(a) Disconnect the K11 electrical key and tire pressure monitoring system receiver assembly connector.

(b) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K11-6 (CSEL) - K10-20 (CSEL) |

Always | Below 1 Ω |

|

K11-6 (CSEL) or K10-20 (CSEL) - Other terminals and body ground |

Always | 10 kΩ or higher |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 33. |

CHECK ENTRY LOCK OPERATION |

(a) Connect all connectors and check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 34. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 35. |

CHECK ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER ASSEMBLY |

(a) Enter key diagnostic mode and select the channel for which the wireless buzzer did not sound.

| (b) Using an oscilloscope, check the waveform. OK:

HINT: Inspection should be performed while the electrical key antenna check in key diagnostic mode is being performed on the failed channel (the channel in which the buzzer did not sound). |

|

| NG |  | REPLACE ELECTRICAL KEY AND TIRE PRESSURE MONITORING SYSTEM RECEIVER ASSEMBLY |

|

| 36. |

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

(a) Replace the certification ECU (smart key ECU assembly) and perform registration again.

HINT:

Click here

Click here

|

| 37. |

CHECK WIRELESS DOOR LOCK CONTROL SYSTEM |

(a) Check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Wireless door lock function operates normally |

A |

| Wireless door lock function does not operate normally |

B |

| A |

| END (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) WAS DEFECTIVE) |

| B |

| REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

DESCRIPTION

When the wireless operation can be used to lock and unlock the doors, communication between the electrical key and tire pressure monitoring system receiver assembly and certification ECU (smart key ECU assembly) is normal. If the entry lock and unlock functions do not operate, the entry cancel function may be set through the customize function, there may be communication problems between the electrical key transmitter sub-assembly and vehicle, or there may be wave interference.

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

Click here

PROCEDURE

|

1. | CHECK POWER DOOR LOCK CONTROL SYSTEM |

(a) When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation.

Click here

OK:

Door locks operate normally.

| NG |  |

GO TO POWER DOOR LOCK CONTROL SYSTEM (for Gasoline Model) |

|

| 2. |

CHECK WAVE ENVIRONMENT |

(a) Move the electrical key transmitter sub-assembly as described below and perform the operation inspection.

HINT:

| (1) Bring the electrical key transmitter sub-assembly approximately 0.3 m (0.984 ft.) from the front door outside handle assembly (for driver door) and perform a driver door entry lock and unlock operation check. HINT: Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the door handle. |

|

| (2) Bring the electrical key transmitter sub-assembly approximately 0.3 m (0.984 ft.) from the front door outside handle assembly (for front passenger door) and perform a front passenger door entry lock and unlock operation check. HINT: Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the door handle. |

|

| (3) Bring the electrical key transmitter sub-assembly approximately 0.3 m (0.984 ft.) from the electrical key antenna (outside luggage compartment) and perform an entry luggage compartment door open function check. HINT: Communication may not be possible if the electrical key transmitter sub-assembly is within 0.2 m (0.656 ft.) of the rear bumper. |

|

|

Result | Proceed to |

|---|---|

|

All operation checks fail |

A |

| All operation checks are normal |

B |

| Some operation checks are normal |

C |

| B |

| AFFECTED BY WAVE INTERFERENCE |

| C |

| GO TO OTHER PROBLEM |

|

| 3. |

CHECK KEY DIAGNOSTIC MODE |

(a) Check the following antennas in key diagnostic mode.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

(b) Select either channel 1 or channel 2 and perform key diagnostic mode inspection for each channel.

| (1) Check the electrical key antenna (for driver door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly (for driver door), check that the wireless buzzer sounds. HINT:

|

|

| (2) Check the electrical key antenna (for front passenger door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly (for front passenger door), check that the wireless buzzer sounds. HINT:

|

|

| (3) Check the electrical key antenna (outside luggage compartment): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the electrical key antenna (outside luggage compartment), check that the wireless buzzer sounds. HINT:

OK: Wireless buzzer sounds. |

|

|

Result | Proceed to |

|---|---|

|

All diagnostic mode inspections fail |

A |

| Some diagnostic mode inspections fail (door) |

B |

| Some diagnostic mode inspections fail (outside luggage compartment) |

C |

| All diagnostic mode inspections are normal |

D |

| B |

| GO TO OTHER PROBLEM |

| C |

| GO TO OTHER PROBLEM |

| D |

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 4. |

CHECK ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY |

(a) Check if there is another electrical key transmitter sub-assembly available that is already registered to the vehicle.

|

Result | Proceed to |

|---|---|

|

Another registered electrical key transmitter sub-assembly is not available |

A |

| Another registered electrical key transmitter sub-assembly is available |

B |

| B |

| GO TO STEP 6 |

|

| 5. |

ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY REGISTRATION (NEW ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY) |

(a) Register a new electrical key transmitter sub-assembly.

Click here

|

| 6. |

CHECK ENTRY LOCK OPERATION |

(a) Using another registered electrical key transmitter sub-assembly, check that the entry function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function operates normally |

A |

| Entry function does not operate normally |

B |

| A |

| END (ELECTRICAL KEY TRANSMITTER SUB-ASSEMBLY WAS DEFECTIVE) |

| B |

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

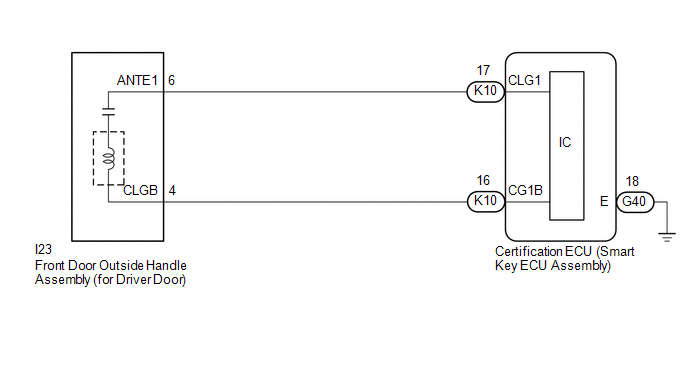

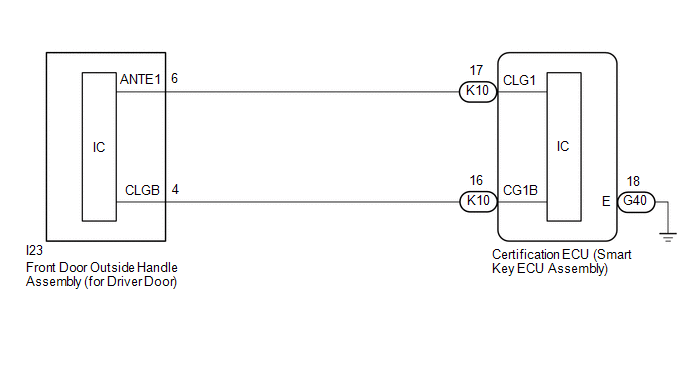

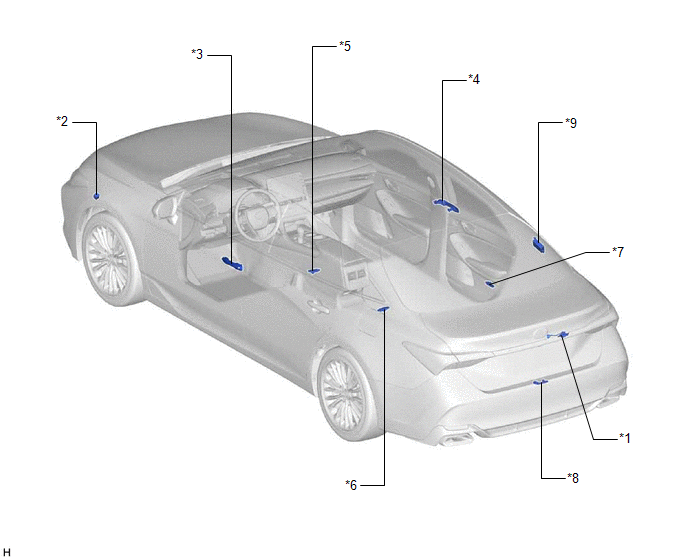

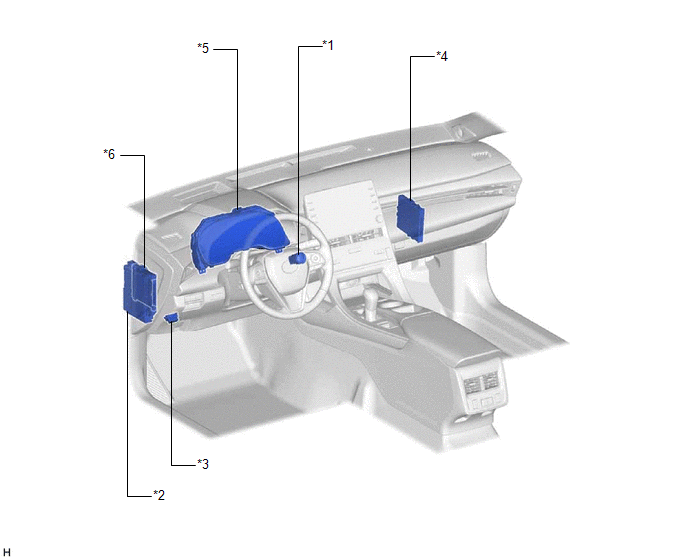

DESCRIPTION

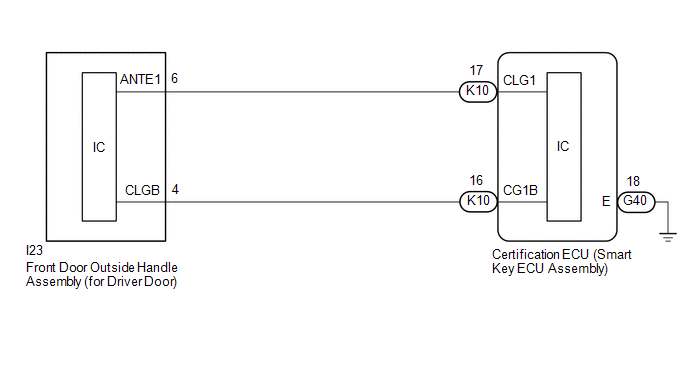

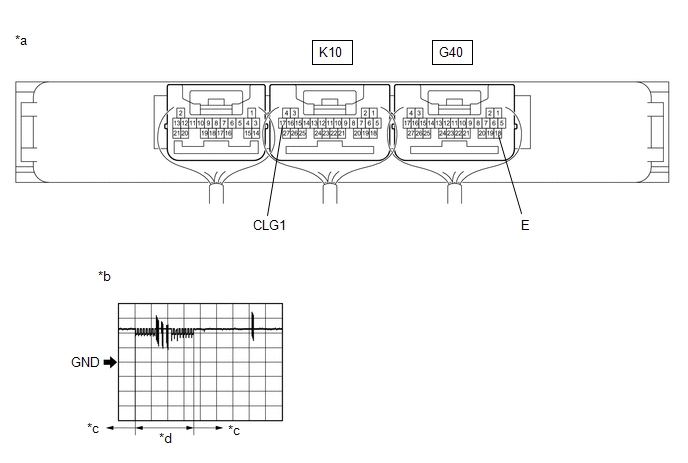

The certification ECU (smart key ECU assembly) generates a request signal and transmits the signal to the front door outside handle assembly (for driver door) (electrical key antenna) at intervals of 0.25 seconds. For the front door outside handle assembly (for driver door) (electrical key antenna) to detect when the electrical key transmitter sub-assembly is brought close to the vehicle, a signal requesting a response from the electrical key transmitter sub-assembly is transmitted within approximately 1 m (3.28 ft.) of the driver door at intervals of 0.25 seconds. DTC B27A1 is stored by the certification ECU (smart key ECU assembly) when an open is detected between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door) (electrical key antenna) (between terminals CLG1 and ANTE1, or terminals CG1B and CLGB).

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B27A1 |

Open in Driver Side Electrical Antenna Circuit |

An open is detected in the circuit between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door) (CLG1 - ANTE1, CG1B - CLGB) (This is detected by the malfunction detection circuit in the certification ECU (smart key ECU assembly)) (1 trip detection logic*). |

|

|

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Entry lock/unlock operation cannot be performed for driver door |

- |

|

DTC No. | Data List and Active Test |

|---|---|

|

B27A1 | Key diagnostic mode can be used to perform troubleshooting |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

PROCEDURE

|

1. | CHECK CONNECTOR CONNECTION |

(a) Check that the connectors are properly connected to the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door).

OK:

Connectors are properly connected.

| NG |  | CONNECT CONNECTORS PROPERLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the I23 front door outside handle assembly (for driver door) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-17 (CLG1) - I23-6 (ANTE1) |

Always | Below 1 Ω |

|

K10-16 (CG1B) - I23-4 (CLGB) |

Always | Below 1 Ω |

(d) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

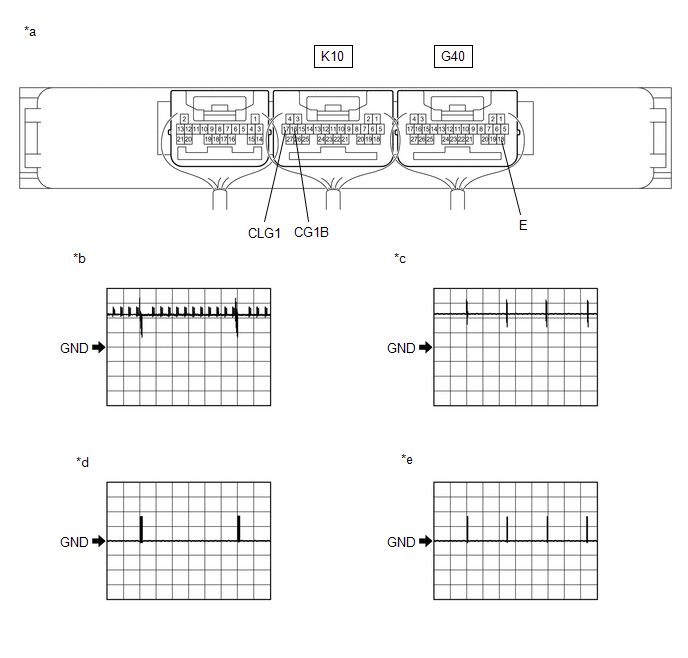

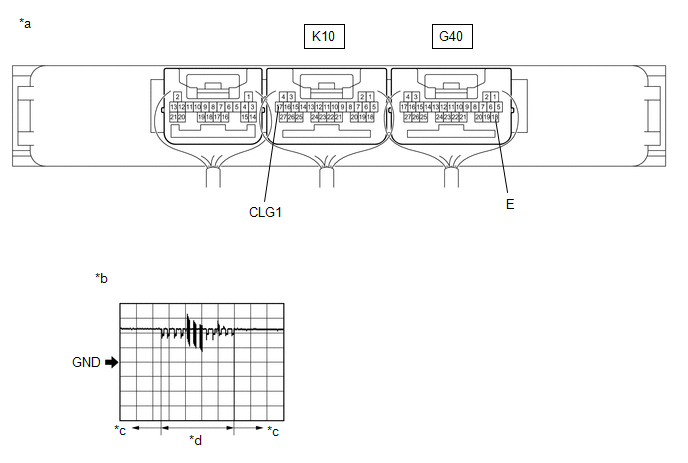

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR)) |

|

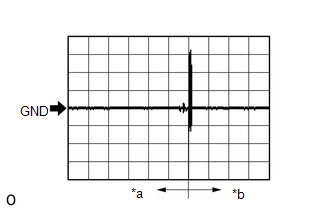

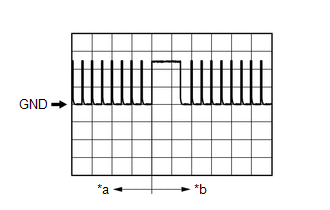

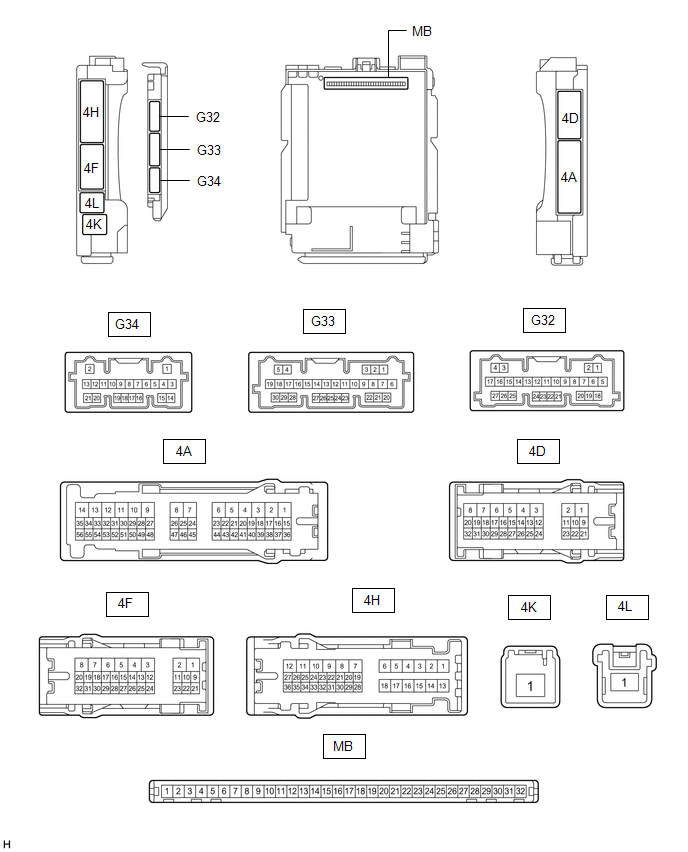

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

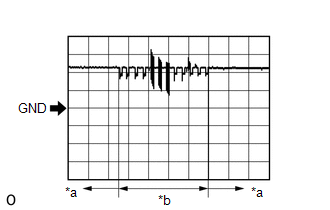

*b | Waveform 1 |

|

*c | Waveform 2 |

*d | Waveform 3 |

|

*e | Waveform 4 | - |

- |

(a) Using an oscilloscope, check the waveform.

OK:

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

K10-17 (CLG1) - G40-18 (E) | Procedure:

| 5 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

|

Procedure:

| 5 V/DIV., 100 ms/DIV. |

Pulse generation (See waveform 2) | |

|

K10-16 (CG1B) - G40-18 (E) | Procedure:

| 5 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 3) |

|

Procedure:

| 5 V/DIV., 100 ms/DIV. |

Pulse generation (See waveform 4) |

Click here

| OK |  | REPLACE FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) |

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and transmits the signal to the front door outside handle assembly (for front passenger door) (electrical key antenna) at intervals of 0.25 seconds. For the front door outside handle assembly (for front passenger door) (electrical key antenna) to detect when the electrical key transmitter sub-assembly is brought close to the vehicle, a signal requesting a response from the electrical key transmitter sub-assembly is transmitted within approximately 1 m (3.28 ft.) of the front passenger door at intervals of 0.25 seconds. DTC B27A2 is stored by the certification ECU (smart key ECU assembly) when an open is detected between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for front passenger door) (electrical key antenna) (between terminals CLG2 and ANTE2, or terminals CG2B and CLGB).

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B27A2 |

Open in Front Passenger Side Electrical Antenna Circuit |

An open is detected in the circuit between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for front passenger door) (CLG2 - ANTE2, CG2B - CLGB) (This is detected by the malfunction detection circuit in the certification ECU (smart key ECU assembly)) (1 trip detection logic*). |

|

|

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Entry lock/unlock operation cannot be performed for front passenger door |

- |

|

DTC No. | Data List and Active Test |

|---|---|

|

B27A2 | Key diagnostic mode can be used to perform troubleshooting |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

PROCEDURE

|

1. | CHECK CONNECTOR CONNECTION |

(a) Check that the connectors are properly connected to the certification ECU (smart key ECU assembly) and front door outside handle assembly (for front passenger door).

OK:

Connectors are properly connected.

| NG |  | CONNECT CONNECTORS PROPERLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR FRONT PASSENGER DOOR)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the I7 front door outside handle assembly (for front passenger door) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-15 (CLG2) - I7-6 (ANTE2) |

Always | Below 1 Ω |

|

K10-14 (CG2B) - I7-4 (CLGB) |

Always | Below 1 Ω |

(d) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR FRONT PASSENGER DOOR)) |

|

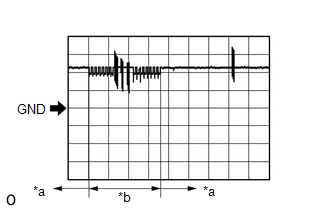

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b | Waveform 1 |

|

*c | Waveform 2 |

*d | Waveform 3 |

|

*e | Waveform 4 |

- | - |

(a) Using an oscilloscope, check the waveform.

OK:

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

K10-15 (CLG2) - G40-18 (E) | Procedure:

| 5 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

|

Procedure:

| 5 V/DIV., 100 ms/DIV. |

Pulse generation (See waveform 2) | |

|

K10-14 (CG2B) - G40-18 (E) | Procedure:

| 5 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 3) |

|

Procedure:

| 5 V/DIV., 100 ms/DIV. |

Pulse generation (See waveform 4) |

Click here

| OK |  | REPLACE FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR FRONT PASSENGER DOOR) |

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and transmits the signal to the No. 1 indoor electrical key antenna assembly (inside luggage compartment). For the No. 1 indoor electrical key antenna assembly (inside luggage compartment) to detect when the electrical key transmitter sub-assembly is in the cabin, the signal from the certification ECU (smart key ECU assembly) requesting a response from the electrical key transmitter sub-assembly is transmitted inside the vehicle. DTC B27A7 is stored by the certification ECU (smart key ECU assembly) when an open is detected between the certification ECU (smart key ECU assembly) and No. 1 indoor electrical key antenna assembly (inside luggage compartment) (between terminals CLG7 and ANTE7, or terminals CG7B and CLGB).

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B27A7 |

Open in Inside Luggage Compartment Electrical Key Oscillator Circuit |

An open is detected in the circuit between the certification ECU (smart key ECU assembly) and No. 1 indoor electrical key antenna assembly (inside luggage compartment) (CLG7 - ANTE7, CG7B - CLGB) (1 trip detection logic*). |

|

|

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

When electrical key transmitter sub-assembly is in luggage compartment:

| - |

|

DTC No. | Data List and Active Test |

|---|---|

|

B27A7 | Key diagnostic mode can be used to perform troubleshooting |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

PROCEDURE

|

1. | CHECK CONNECTOR CONNECTION |

(a) Check that the connectors are properly connected to the certification ECU (smart key ECU assembly) and No. 1 indoor electrical key antenna assembly (inside luggage compartment).

OK:

Connectors are properly connected.

| NG |  | CONNECT CONNECTORS PROPERLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (INSIDE LUGGAGE COMPARTMENT)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the K13 No. 1 indoor electrical key antenna assembly (inside luggage compartment) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-11 (CLG7) - K13-1 (ANTE7) |

Always | Below 1 Ω |

|

K10-10 (CG7B) - K13-3 (CLGB) |

Always | Below 1 Ω |

(d) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (INSIDE LUGGAGE COMPARTMENT)) |

|

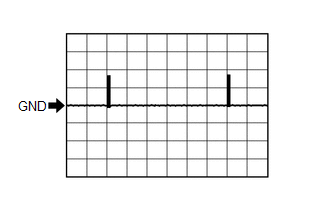

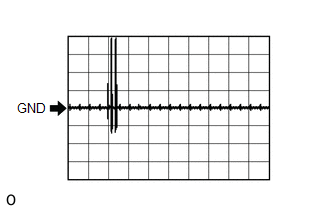

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b | Waveform 1 |

|

*c | Driver door lock sensor not touched |

*d | Driver door lock sensor touched |

(a) Using an oscilloscope, check the waveform.

OK:

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

K10-11 (CLG7) - G40-18 (E) | Procedure:

| 2 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

|

K10-10 (CG7B) - G40-18 (E) | Procedure:

| 2 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

| OK |  | REPLACE NO. 1 INDOOR ELECTRICAL KEY ANTENNA ASSEMBLY (INSIDE LUGGAGE COMPARTMENT) |

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

DESCRIPTION

The certification ECU (smart key ECU assembly) generates a request signal and transmits the signal to the electrical key antenna (outside luggage compartment). For the electrical key antenna (outside luggage compartment) to detect when the electrical key transmitter sub-assembly is brought close to the vehicle, the received request signal is transmitted within approximately 1 m (3.28 ft.) of the Luggage Compartment door. DTC B27A8 is stored by the certification ECU (smart key ECU assembly) when an open is detected between the certification ECU (smart key ECU assembly) and electrical key antenna (outside luggage compartment) (between terminals CLG8 and ANTE8, or terminals CG8B and CLGB).

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

Note |

|---|---|---|---|---|

| B27A8 |

Open in Outside Luggage Compartment Electrical Key Antenna Circuit |

An open is detected in the circuit between the certification ECU (smart key ECU assembly) and electrical key antenna (outside luggage compartment) (CLG8 - ANTE8, CG8B - CLGB) (1 trip detection logic*). |

|

|

|

Vehicle Condition when Malfunction Detected |

Fail-safe Operation when Malfunction Detected |

|---|---|

|

Entry lock/unlock operation cannot be performed for luggage compartment door |

- |

|

DTC No. | Data List and Active Test |

|---|---|

|

B27A8 | Key diagnostic mode can be used to perform troubleshooting |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

PROCEDURE

|

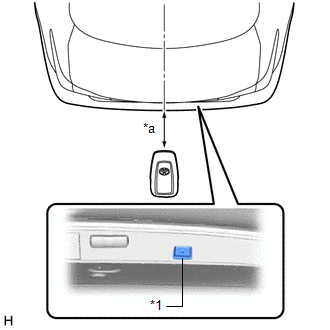

1. | CHECK CONNECTOR CONNECTION |

(a) Check that the connectors are properly connected to the certification ECU (smart key ECU assembly) and electrical key antenna (outside luggage compartment).

OK:

Connectors are properly connected.

| NG |  | CONNECT CONNECTORS PROPERLY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ELECTRICAL KEY ANTENNA (OUTSIDE LUGGAGE COMPARTMENT)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the P2 electrical key antenna (outside luggage compartment) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-13 (CLG8) - P2-2 (ANTE8) |

Always | Below 1 Ω |

|

K10-12 (CG8B) - P2-1 (CLGB) |

Always | Below 1 Ω |

(d) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 3. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO ELECTRICAL KEY ANTENNA (OUTSIDE LUGGAGE COMPARTMENT)) |

|

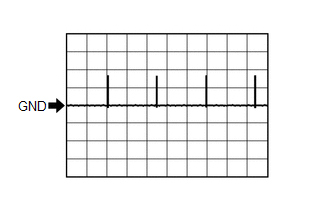

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b | Waveform 1 |

(a) Using an oscilloscope, check the waveform.

OK:

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

K10-13 (CLG8) - G40-18 (E) | Procedure:

| 2 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

|

K10-12 (CG8B) - G40-18 (E) | Procedure:

| 2 V/DIV., 500 ms/DIV. |

Pulse generation (See waveform 1) |

| OK |  | REPLACE ELECTRICAL KEY ANTENNA (OUTSIDE LUGGAGE COMPARTMENT) |

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

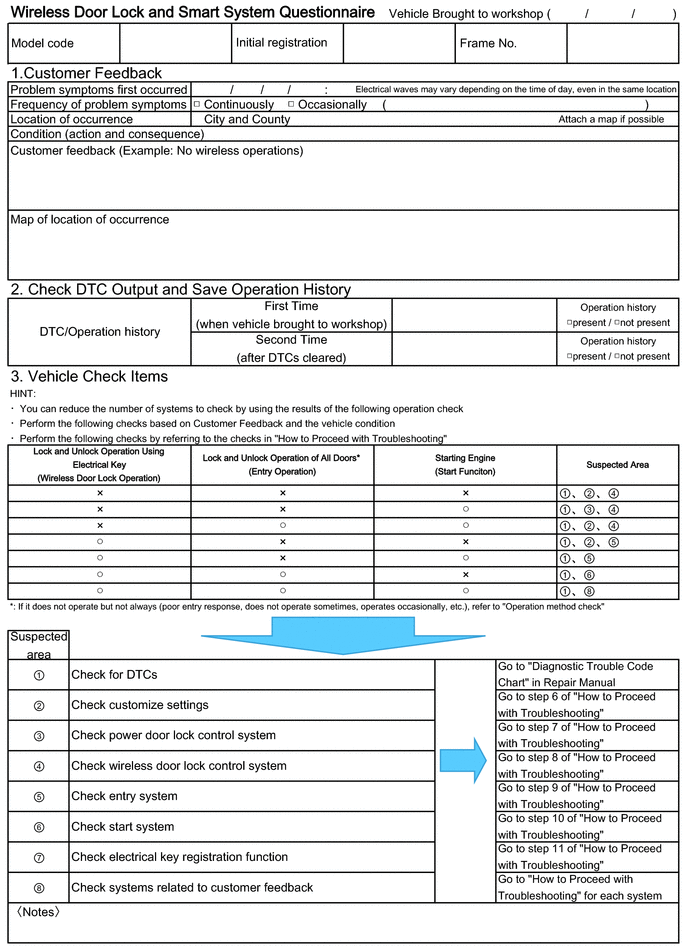

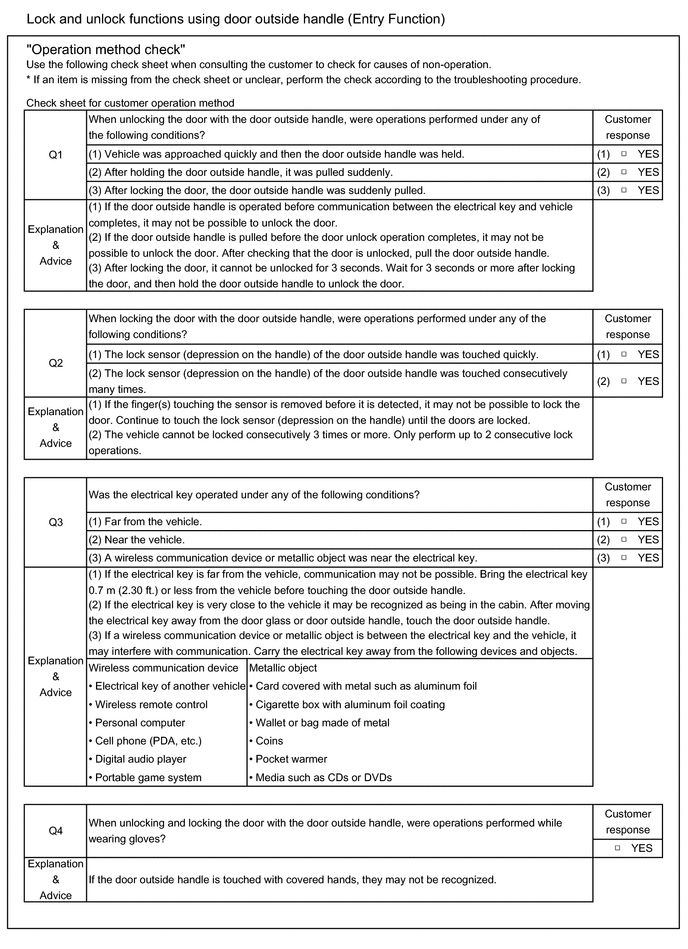

CUSTOMER PROBLEM ANALYSIS CHECK

HINT:

Be sure to ask the customer in detail about the following points concerning the vehicle operating conditions, environment and problem, and then check for DTCs.

If it is suspected that wave interference is likely, be sure to ask the customer in detail about the following points concerning the vehicle operating conditions, environment and problem.

Click here

CUSTOMIZE PARAMETERS

CUSTOMIZE SMART KEY SYSTEM (for Entry Function, Gasoline Model)

NOTICE:

HINT:

The following items can be customized.

(a) Customizing with the Techstream

(1) Connect the Techstream to the DLC3.

(2) Turn the engine switch on (IG).

(3) Turn the Techstream on.

(4) Enter the following menus: Customize Setting / Smart Key / Access or Warning.

(5) Select the setting by referring to the table below.

Smart Key / Access|

Tester Display | Description |

Default | Setting |

ECU |

|---|---|---|---|---|

| Park Wait Time |

Function that sets the period of time (lock confirmation time) that the door is prevented from being unlocked by operating the front door outside handle assembly or rear door outside handle assembly after an entry lock operation is performed. | 2.5s |

00:0.5s,01:1.5s,10:2.5s,11:5s |

Certification ECU (Smart key ECU assembly) |

|

Ignition Available Area |

Function that sets the area that the key must be in before the engine switch can be operated. |

All | 00:Front,01:All |

Certification ECU (Smart key ECU assembly) |

|

Trunk Open Mode | Function that opens the luggage compartment door when the user is carrying the electrical key transmitter sub-assembly and presses the luggage electrical key switch. | ON |

0:OFF,1:ON | Certification ECU (Smart key ECU assembly) |

|

Door Unlock Mode2 | Function that sets which doors are unlocked by the entry unlock function. |

All | 0:All,1:Driver |

Certification ECU (Smart key ECU assembly) |

|

Touch Activation Over Threshold |

Function that limits the number of times the entry lock function can be operated consecutively. When set to Not Active entry lock function can be operated an unlimited number of times consecutively. |

Active | 0:Active,1:Not Active |

Certification ECU (Smart key ECU assembly) |

|

Door Unlock Sensor Touch Time Adjust |

Function that sets the length of time the unlock sensor on the door outside handle assembly (for driver door) must be touched to unlock all of the doors | Middle |

00:OFF,01:Short,10:Middle,11:Long |

Certification ECU (Smart key ECU assembly) |

|

Tester Display | Description |

Default | Setting |

ECU |

|---|---|---|---|---|

| Key Low Battery Warning |

Enables or disables the sounding of the buzzer when the transmitter battery is low and the engine switch is turned off after being on (IG) for 20 minutes or more. | ON |

0:OFF,1:ON | Certification ECU (Smart key ECU assembly) |

(b) Customizing with the multi-display

(1) Turn the engine switch on (IG).

(2) Enter the following menus: MENU / Setup / Vehicle / Vehicle Customization / Door Lock Settings.

(3) Select the setting by referring to the table below.

|

Display | Description |

Default | Setting |

Relevant ECU |

|---|---|---|---|---|

| Select Doors to Unlock |

Function that sets which doors are unlocked by the entry unlock function. |

All Doors | All Doors or Driver's Door |

Certification ECU (Smart key ECU assembly) |

(c) Entry unlock mode change function (manual operation)

(1) The following entry unlock modes can be selected when using the entry unlock mode change function.

(2) When customizing through manual operation:

HINT:

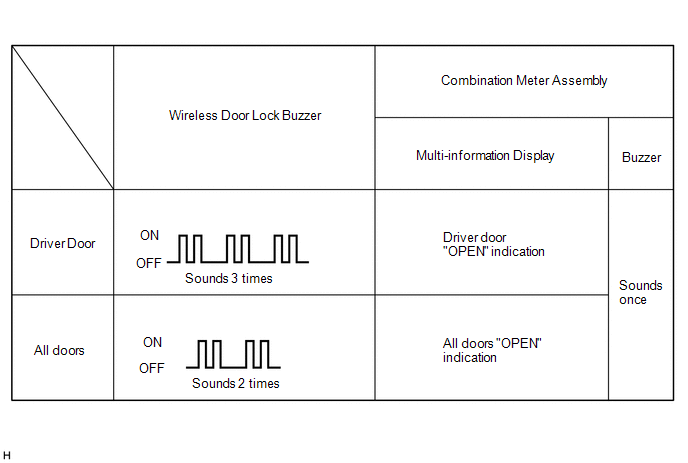

|

Currently Selected Mode |

Answer-back (Wireless Buzzer) |

Answer-back (Buzzer in Combination Meter Assembly) |

|

All door unlock mode |

Buzzer sounds twice (short beeps) |

Buzzer sounds once |

|

Driver door unlock mode |

Buzzer sounds 3 times (short beeps) |

Buzzer sounds once |

HINT:

Repeat the procedure as necessary to select the desired mode.

(d) Entry cancel function (manual operation)

HINT:

While the smart key system is canceled, it is possible to lock and unlock the doors with the wireless function, and the engine can be started by holding the electrical key transmitter sub-assembly near the engine switch.

(1) The following functions are disabled when the smart key system is canceled.

(2) When canceling the smart key system through manual operation:

(3) Press the unlock switch of the electrical key transmitter sub-assembly.

(4) Open the driver door within 5 seconds of completing the step above (driver door: closed → opened).

(5) With the driver door open, press the unlock switch of the electrical key transmitter sub-assembly 2 times within 5 seconds of completing the step above.

NOTICE:

If the driver door is closed before or while pressing the unlock switch, the entry cancel setting mode will end.

(6) Perform the following procedure within 30 seconds of completing the step above.

NOTICE:

If the driver door is closed before or while pressing the unlock switch, the entry cancel setting mode will end.

(7) Close the driver door within 5 seconds (driver door: open → closed).

(8) Check that the wireless buzzer sounds twice (short beeps) to confirm that the smart key system has been canceled.

(9) Perform the following procedure to restore the smart key system to the active state from the canceled state.

HINT:

DATA LIST / ACTIVE TEST

DATA LIST

NOTICE:

HINT:

Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key, Main Body, Power Source Control or Combination Meter / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Smart Key > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

D-Door Touch Sensor | Driver door touch sensor (unlock sensor)* |

OFF or ON | OFF: Driver door touch sensor (unlock sensor) not touched ON: Driver door touch sensor (unlock sensor) touched |

|

| P-Door Touch Sensor |

Front passenger door touch sensor (unlock sensor)* |

OFF or ON | OFF: Front passenger door touch sensor (unlock sensor) not touched ON: Front passenger door touch sensor (unlock sensor) touched |

|

| D-Door Trigger Switch |

Driver door touch sensor (lock sensor)* |

OFF or ON | OFF: Driver door touch sensor (lock sensor) not touched ON: Driver door touch sensor (lock sensor) touched |

|

| P-Door Trigger Switch |

Front passenger door touch sensor (lock sensor)* |

OFF or ON | OFF: Front passenger door touch sensor (lock sensor) not touched ON: Front passenger door touch sensor (lock sensor) touched |

|

| Tr/B-Door Unlock SW |

Luggage electrical key switch |

OFF or ON | OFF: Luggage electrical key switch not pushed ON: Luggage electrical key switch pushed |

|

| Unmatched Vehicle-ID |

Key No. (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

The vehicle ID registered in the vehicle and the vehicle ID registered in the electrical key transmitter sub-assembly are different (if a key from another vehicle is brought into the vehicle exterior detection area while the doors are locked, "Yes" is displayed for "Unmatched Vehicle-ID" in the Data List). Other potential causes:

|

| No Response |

Communication response |

No or Yes | No: Communication normal Yes: Communication malfunction |

The vehicle IDs registered in the vehicle and electrical key transmitter sub-assembly match, but there is no response from the electrical key transmitter sub-assembly. (If the electrical key transmitter sub-assembly is not in the detection area or the transmitter battery is depleted resulting in a matching code not being detected when a lock switch or the engine switch is pressed, etc., "Yes" is displayed for "No Response" in the Data List. If there is wave interference in the LF band that the vehicle uses for transmission or the RF band that the electrical key transmitter sub-assembly uses for transmission, "Yes" may be displayed for "No Response" in the Data List.) Other potential causes:

|

| Unmatch Code or Form |

Code format (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

There is an error in the data sent from the electrical key transmitter sub-assembly (if there is wave interference in the RF band that the electrical key transmitter sub-assembly uses for transmission, "Yes" may be displayed for "Unmatch Code or Form", "No Response", "ID Code Difference(Resp)" and "C Code Difference" in the Data List). Other potential causes:

|

| Key Low Battery |

Transmitter battery depleted |

No or Yes | No: Transmitter battery not depleted Yes: Transmitter battery depleted |

The electrical key transmitter sub-assembly sends voltage information to the certification ECU (smart key ECU assembly) when it is transmitting. "Yes" is displayed for the Data List item "Key Low Battery" when this voltage information indicates 2.2 V or less. This Data List item should be checked when the electrical key transmitter sub-assembly is at room temperature (example: at -20°C (-4°F), "Yes" may be displayed even if the transmitter battery is new). |

|

Power Save Cnt 10 Min. |

Number of times power saving control is activated due to electrical key transmitter sub-assembly being in detection area for 10 minutes or more |

0 to 255 | Within range of 0 to 255 |

If the electrical key transmitter sub-assembly is in a vehicle exterior detection area, communication is frequently performed between the vehicle and electrical key transmitter sub-assembly, resulting in an increase in transmitter battery power consumption. To prevent the transmitter battery from becoming fully depleted, if the electrical key transmitter sub-assembly is left in the detection area for 10 minutes or more, the smart key system automatically deactivates the exterior detection area the electrical key transmitter sub-assembly is in. If the doors are locked/unlocked with a wireless operation or by the mechanical key, the system resumes operation. |

|

Power Save Cnt 5 Days | Number of times power saving control 1 (vehicle exterior periodic signal transmission stop) is activated due to engine not being started for 5 days or more | 0 to 255 |

Within range of 0 to 255 |

- |

| Power Save Cnt 14 Days |

Number of times power saving control 2 (lock/unlock sensor of front door outside handle assembly of front passenger door disabled) is activated due to engine not being started for 14 days or more |

0 to 255 | Within range of 0 to 255 |

- |

| # Codes |

Number of trouble codes |

0 to 255 | Number of stored DTCs displayed |

- |

| ID Code Difference(Resp) |

ID code (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

The ID code registered in the vehicle and the ID code registered in the electrical key transmitter sub-assembly are different (if there is wave interference in the RF band that the electrical key transmitter sub-assembly uses for transmission, "Yes" may be displayed for "Unmatch Code or Form", "No Response", "ID Code Difference(Resp)" and "C Code Difference" in the Data List). Other potential causes:

|

| C Code Difference |

Challenge code (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

The electrical key transmitter sub-assembly sends a response code in response to the challenge code from the vehicle, but the response code is incorrect (if there is wave interference in the RF band that the electrical key transmitter sub-assembly uses for transmission, "Yes" may be displayed for "Unmatch Code or Form", "No Response", "ID Code Difference(Resp)" and "C Code Difference" in the Data List). Other potential causes:

|

| ID Code Difference |

Wireless ID code (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

The ID code registered in the vehicle and the ID code registered in the electrical key transmitter sub-assembly are different. (If a wireless ID other than those for any of the registered electrical key transmitter sub-assemblies is detected, "Yes" is displayed for "ID Code Difference" in the Data List. If a wireless signal from the electrical key transmitter sub-assembly of another vehicle is detected, "Yes" is displayed for "ID Code Difference(Resp)" in the Data List.) Other potential causes:

|

| Different Rolling Code |

Rolling code (incorrect or correct) |

No or Yes | No: Communication normal Yes: Communication malfunction |

The rolling code registered in the vehicle and the rolling code registered in the electrical key transmitter sub-assembly are different Other potential causes:

|

| B Code Difference |

B code mismatch | No or Yes |

No: Communication normal Yes: Communication malfunction |

- |

| B Code |

B code registration status |

No Regd or Regd | No Regd: B code not registered correctly Regd: B code registered correctly |

- |

| B Code Registration Status |

B code registration status |

OK or NG | OK: B code is registered properly NG: B code is not registered properly |

- |

| Door Unlock Mode2 |

Door unlock mode | All or Driver |

Customize setting displayed |

- |

| Ignition Available Area |

Ignition available area |

Front or All | Customize setting displayed |

- |

| Parking Wait Time |

Parking wait time | 0.5s, 1.5s, 2.5s or 5s |

Customize setting displayed |

- |

| Trunk Open Mode |

Entry luggage compartment open mode |

OFF or ON | Customize setting displayed |

- |

| Touch Activation Over Threshold |

Consecutive entry lock operation |

Active or Not Active | Customize setting displayed |

- |

| Wireless Signal Encryption Support |

Wireless signal encryption support |

No or Yes | No: Wireless signal encryption not supported Yes: Wireless signal encryption supported |

- |

| Key Low Battery Warning |

Low transmitter battery warning |

OFF or ON | Customize setting displayed |

- |

| Key Left in Vehicle Buz |

Key left in vehicle buzzer |

OFF or ON | Customize setting displayed |

- |

| Engine Start Indicator |

Key indicator display |

OFF or ON | Customize setting displayed |

- |

| Door Unlock Sensor Touch Time Adjust |

Length of time the unlock sensor on the door outside handle assembly (for driver door) must be touched to unlock all of the doors |

OFF, Short, Middle or Long |

Customize setting displayed |

- |

| Number of Registered Key Codes |

Number of registered electrical key transmitter sub-assemblies |

0 to 8 | Number of registered electrical key transmitter sub-assemblies |

Up to 7 electrical key transmitter sub-assemblies can be registered. |

|

Short in Fr P Side Door Oscillators Circuit (Hist) |

Short in front passenger door electrical key antenna circuit (history) |

OK or NG(Hist) | OK: Front passenger door electrical key antenna circuit was normal NG(Hist): Front passenger door electrical key antenna circuit was abnormal |

- |

| Short in D Side Door Oscillators Circuit (Hist) |

Short in driver door electrical key antenna circuit (history) |

OK or NG(Hist) | OK: Driver door electrical key antenna circuit was normal NG(Hist): Driver door electrical key antenna circuit was abnormal |

- |

| Short in Front P Side Door Oscillators Circuit |

Short in front passenger door electrical key antenna circuit |

OK or NG | OK: Front passenger door electrical key antenna circuit is normal NG: Front passenger door electrical key antenna circuit is abnormal |

- |

| Short in Driver Side Door Oscillators Circuit |

Short in driver door electrical key antenna circuit |

OK or NG | OK: Driver door electrical key antenna circuit is normal NG: Driver door electrical key antenna circuit is abnormal |

- |

HINT:

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ACC SW | Engine switch status |

OFF or ON | OFF: Engine switch off ON: Engine switch on (ACC) |

"ON" is also displayed when the engine switch is on (IG). |

|

IG SW | Engine switch status |

OFF or ON | OFF: Engine switch off ON: Engine switch on (IG) |

"OFF" is also displayed when the engine switch is on (ACC). |

|

RR Door Courtesy SW | Rear door RH courtesy light switch |

OFF or ON | OFF: Rear door RH closed ON: Rear door RH open |

- |

| RL Door Courtesy SW |

Rear door LH courtesy light switch |

OFF or ON | OFF: Rear door LH closed ON: Rear door LH open |

- |

| FR Door Lock Pos |

Front door RH unlock detection switch signal |

UNLOCK or LOCK | UNLOCK: Front door RH unlocked LOCK: Front door RH locked |

- |

| FR Door Courtesy SW |

Front door RH courtesy light switch signal |

OFF or ON | OFF: Front door RH closed ON: Front door RH open |

- |

| FL Door Lock Pos |

Front door LH unlock detection switch signal |

UNLOCK or LOCK | UNLOCK: Front door LH unlocked LOCK: Front door LH locked |

- |

| FL Door Courtesy SW |

Front door LH courtesy light switch signal |

OFF or ON | OFF: Front door LH closed ON: Front door LH open |

- |

| RR-Door Lock Pos SW |

Rear door RH unlock detection switch signal |

OFF or ON | OFF: Rear door RH locked ON: Rear door RH unlocked |

- |

| RL-Door Lock Pos SW |

Rear door LH unlock detection switch signal |

OFF or ON | OFF: Rear door LH locked ON: Rear door LH unlocked |

- |

| Luggage Courtesy SW |

Luggage compartment door lock courtesy light switch signal |

OFF or ON | OFF: Luggage compartment door closed ON: Luggage compartment door open |

- |

| Wireless Buzzer Resp |

Wireless buzzer answer-back of entry function |

OFF or ON | Customize setting displayed |

- |

|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Power Supply Condition |

Power supply state | All OFF, ACC ON, IG ON or ST ON |

All OFF: Engine switch off ACC ON: Engine switch on (ACC) IG ON: Engine switch on (IG) ST ON: Sending engine start request signal |

- |

ACTIVE TEST

HINT:

Using the Techstream to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Smart Key or Main Body / Active Test.

(e) Perform Active Test according to the display on the Techstream.

Body Electrical > Smart Key > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Overhead Tuner Power Supply ON |

Electrical key and tire pressure monitoring system receiver assembly |

OFF/ON | - |

|

Power for P-Seat Sens | Front door outside handle (for front passenger door) |

OFF/ON | - |

|

Multi Channel SW | Electrical key and tire pressure monitoring system receiver assembly |

CH1/CH2 | - |

|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Door Lock | Door lock motor |

OFF/Unlock/Lock | - |

|

D-Door Unlock | Driver door lock motor |

OFF/ON | - |

|

Trunk and Back-Door Open |

Luggage compartment door lock motor |

OFF/ON | - |

|

Wireless Buzzer | Wireless door lock buzzer |

OFF/ON | - |

DIAGNOSTIC TROUBLE CODE CHART

Smart Key System (for Entry Function, Gasoline Model)|

DTC No. | Detection Item |

Link |

|---|---|---|

| B27A1 |

Open in Driver Side Electrical Antenna Circuit |

|

|

B27A2 | Open in Front Passenger Side Electrical Antenna Circuit |

|

|

B27A7 | Open in Inside Luggage Compartment Electrical Key Oscillator Circuit |

|

|

B27A8 | Open in Outside Luggage Compartment Electrical Key Antenna Circuit |

|

DESCRIPTION

If the entry lock and unlock functions do not operate for the driver door only, the request code may not be being transmitted from the driver door or the front door outside handle assembly (for driver door) (touch sensor) may be malfunctioning. If the entry functions for other doors operate properly, communication between the electrical key transmitter sub-assembly and electrical key and tire pressure monitoring system receiver assembly is normal. In this case, there may be a problem with request code transmission (communication between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door) (electrical key antenna)), or there may be wave interference.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

HINT:

|

Tester Display |

|---|

| Operation History |

PROCEDURE

| 1. |

CHECK POWER DOOR LOCK CONTROL SYSTEM |

(a) When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation.

Click here

OK:

Door locks operate normally.

| NG |  | GO TO POWER DOOR LOCK CONTROL SYSTEM |

|

| 2. |

CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Smart Key > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTCs are not output | A |

|

DTCs are output | B |

| B |

| GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

| 3. |

CHECK WAVE ENVIRONMENT |

| (a) Bring the electrical key transmitter sub-assembly approximately 0.3 m (0.984 ft.) from the front door outside handle assembly (for driver door) and perform an entry function check. Click here

|

|

| Result |

Proceed to |

|---|---|

| Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| AFFECTED BY WAVE INTERFERENCE |

|

| 4. |

READ VALUE USING TECHSTREAM (D-DOOR TOUCH SENSOR) |

(a) Turn the engine switch off.

(b) Open and close the driver door.

(c) With the electrical key transmitter sub-assembly outside of the vehicle, press the lock switch of the electrical key transmitter sub-assembly to lock all of the doors.

(d) Hold the electrical key transmitter sub-assembly at the same height as the door outside handle assembly and approximately 0.3 m (0.984 ft.) from the driver door.

(e) Check that the LED of the electrical key transmitter sub-assembly blinks.

(f) Read the Data List according to the display on the Techstream.

| (g) Touch the unlock sensor on the backside of the front door outside handle assembly (for driver door). HINT: When checking the operation of the unlock sensor again, make sure to perform the procedure from step (a). Body Electrical > Smart Key > Data List

OK: The Techstream display changes correctly in response to the operation of the front door outside handle assembly (for driver door). |

|

| NG |  | GO TO STEP 7 |

|

| 5. |

READ VALUE USING TECHSTREAM (D-DOOR TRIGGER SWITCH) |

(a) Turn the engine switch off.

(b) Open and close the driver door.

(c) Hold the electrical key transmitter sub-assembly at the same height as the door outside handle assembly and approximately 0.3 m (0.984 ft.) from the driver door.

(d) Read the Data List according to the display on the Techstream.

| (e) Touch the lock sensor of the front door outside handle assembly (for driver door). HINT:

HINT: When checking the operation of the entry lock function several times, it can be operated up to 2 times consecutively. To operate the function 3 times or more consecutively, the doors need to be unlocked once. However, this is only for the entry lock function, other door lock operations, such as a wireless door lock operation can be performed consecutively. OK: The Techstream display changes correctly in response to the operation of the front door outside handle assembly (for driver door). |

|

| NG |  | GO TO STEP 7 |

|

| 6. |

CHECK KEY DIAGNOSTIC MODE |

(a) Check the following antenna in key diagnostic mode.

Body Electrical > Smart Key > Utility|

Tester Display |

|---|

| Communication Check(Key Diag Mode) |

(b) Select either channel 1 or channel 2 and perform key diagnostic mode inspection for each channel.

| (1) Check the electrical key antenna (for driver door): When the electrical key transmitter sub-assembly is brought within 0.7 to 1 m (2.30 to 3.28 ft.) of the front door outside handle assembly (for driver door), check that the wireless buzzer sounds. HINT:

|

|

|

Result | Proceed to |

|---|---|

|

Wireless buzzer does not sound |

A |

| Wireless buzzer sounds |

B |

| B |

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 7. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the I23 front door outside handle assembly (for driver door) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-17 (CLG1) - I23-6 (ANTE1) |

Always | Below 1 Ω |

|

K10-16 (CG1B) - I23-4 (CLGB) |

Always | Below 1 Ω |

|

K10-17 (CLG1) or I23-6 (ANTE1) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

K10-16 (CG1B) or I23-4 (CLGB) - Other terminals and body ground |

Always | 10 kΩ or higher |

(d) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (OUTPUT TO DRIVER DOOR ELECTRICAL KEY ANTENNA) |

| (a) Using an oscilloscope, check the waveform. OK:

*: For details about the entry function detection area, refer to Operation Check. Click here |

|

| NG |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 9. |

CHECK ENTRY LOCK OPERATION |

(a) Connect all connectors and check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function does not operate normally |

A |

| Entry function operates normally |

B |

| B |

| END (CONNECTOR WAS NOT CONNECTED SECURELY) |

|

| 10. |

REPLACE FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) |

(a) Replace the front door outside handle assembly (for driver door) with a new one or the front door outside handle assembly (for front passenger door) if it is functioning properly.

Click here

|

| 11. |

CHECK ENTRY LOCK OPERATION |

(a) Check that the function operates normally.

Click here

|

Result | Proceed to |

|---|---|

|

Entry function operates normally |

A |

| Entry function does not operate normally |

B |

| A |

| END (FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) WAS DEFECTIVE) |

| B |

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

DESCRIPTION

If the entry lock function does not operate for the driver door only, but the entry unlock function operates, the request code is being transmitted properly from the driver door. In this case, there may be a problem related to the lock sensor (connection between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door)).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

PROCEDURE

|

1. | CHECK POWER DOOR LOCK CONTROL SYSTEM |

(a) When the door control switch on the multiplex network master switch assembly is operated, check that the doors unlock and lock according to the switch operation.

Click here

OK:

Door locks operate normally.

| NG |  |

GO TO POWER DOOR LOCK CONTROL SYSTEM |

|

| 2. |

READ VALUE USING TECHSTREAM (D-DOOR TRIGGER SWITCH) |

(a) Turn the engine switch off.

(b) Open and close the driver door.

(c) Hold the electrical key transmitter sub-assembly at the same height as the door outside handle assembly and approximately 0.3 m (0.984 ft.) from the driver door.

(d) Read the Data List according to the display on the Techstream.

| (e) Touch the lock sensor of the front door outside handle assembly (for driver door). HINT:

HINT: When checking the operation of the entry lock function several times, it can be operated up to 2 times consecutively. To operate the function 3 times or more consecutively, the doors need to be unlocked once. However, this is only for the entry lock function, other door lock operations, such as a wireless door lock operation can be performed consecutively. OK: The Techstream display changes correctly in response to the operation of the front door outside handle assembly (for driver door). |

|

| OK |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|

| 3. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR)) |

(a) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the I23 front door outside handle assembly (for driver door) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

K10-17 (CLG1) - I23-6 (ANTE1) |

Always | Below 1 Ω |

|

K10-16 (CG1B) - I23-4 (CLGB) |

Always | Below 1 Ω |

|

K10-17 (CLG1) or I23-6 (ANTE1) - Other terminals and body ground |

Always | 10 kΩ or higher |

|

K10-16 (CG1B) or I23-4 (CLGB) - Other terminals and body ground |

Always | 10 kΩ or higher |

(d) Reconnect the I23 front door outside handle assembly (for driver door) connector.

(e) Reconnect the K10 certification ECU (smart key ECU assembly) connector.

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

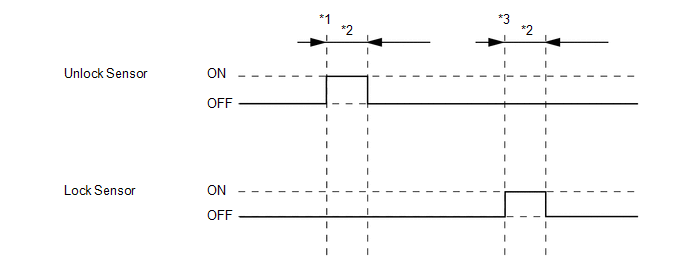

| 4. |

CHECK FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) (INPUT TO CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)) |

|

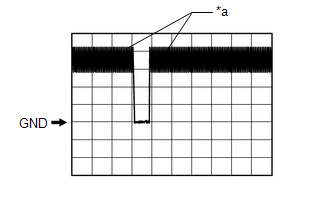

*a | Component with harness connected (Certification ECU (Smart Key ECU Assembly)) |

*b | Waveform 1 |

|

*c | Lock sensor not touched |

*d | Lock sensor touched |

(a) Using an oscilloscope, check the waveform.

OK:

|

Tester Connection | Condition |

Tool Setting | Specified Condition |

|---|---|---|---|

|

K10-17 (CLG1) - G40-18 (E) |

Procedure:

| 5 V/DIV., 40 ms/DIV. |

Pulse generation (See waveform 1) |

*: For details about the entry function detection area, refer to Operation Check.

Click here

| OK |  | REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

| NG |  | REPLACE FRONT DOOR OUTSIDE HANDLE ASSEMBLY (FOR DRIVER DOOR) |

DESCRIPTION

If the entry unlock function does not operate for the driver door only, but the entry lock function operates, the request code is being transmitted properly from the driver door. In this case, there may be a problem related to the unlock sensor (connection between the certification ECU (smart key ECU assembly) and front door outside handle assembly (for driver door)).