DESCRIPTION

The skid control ECU (brake actuator assembly) receives signals from the yaw rate and acceleration sensor (airbag sensor assembly) via CAN communication.

The airbag sensor assembly has a built-in yaw rate and acceleration sensor and detects the vehicle's condition using 2 circuits (GL1, GL2). If a communication error with the yaw rate and acceleration sensor (airbag sensor assembly) is detected, DTCs U0123 (Lost Communication With Yaw Rate Sensor Module) and U0151 (Lost Communication With Restraints Control Module) are stored.

The DTCs are also stored when the calibration has not been completed.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

C1336 | Zero Point Calibration of Deceleration Sensor undone |

Zero point calibration of acceleration sensor undone. |

|

CAUTION / NOTICE / HINT

NOTICE:

Click here

Click here

HINT:

When U0123 and/or U0151 is output together with C1336, inspect and repair the trouble areas indicated by U0123 and/or U0151 first.

Click here

PROCEDURE

| 1. |

PERFORM ZERO POINT CALIBRATION OF YAW RATE AND ACCELERATION SENSOR |

(a) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Utility / Test Mode.

(b) Perform zero point calibration of the yaw rate and acceleration sensor.

Click here

|

Tester Display |

|---|

| Test Mode |

|

| 2. |

PERFORM TEST MODE INSPECTION (SIGNAL CHECK) |

(a) Turn the engine switch off.

(b) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Utility / Signal Check.

(c) Using the Techstream, perform a Test Mode (Signal Check) inspection sensor check and check that all Test Mode (Signal Check) inspection items change from incomplete to complete.

Click here

|

Tester Display |

|---|

| Signal Check |

OK:

All Test Mode (Signal Check) inspection items change from incomplete to complete

| OK |  | END |

|

| 3. |

CHECK AIRBAG SENSOR ASSEMBLY INSTALLATION |

(a) Turn the engine switch off.

(b) Check that the yaw rate and acceleration sensor (airbag sensor assembly) has been installed properly.

Click here

OK:

The yaw rate and acceleration sensor (airbag sensor assembly) is tightened to the specified torque.

The yaw rate and acceleration sensor (airbag sensor assembly) is not installed in a tilted position.

| NG |  | INSTALL AIRBAG SENSOR ASSEMBLY CORRECTLY |

|

| 4. |

READ VALUE USING TECHSTREAM (ACCELERATION SENSOR) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Data List.

Chassis > ABS/VSC/TRAC/EPB > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Deceleration Sensor | Acceleration sensor reading |

Min.: -18.525 m/s2 Max.: 18.387 m/s2 |

- | During deceleration/acceleration: Changes continuously |

|

Deceleration Sensor2 | Acceleration sensor 2 reading |

Min.: -18.525 m/s2 Max.: 18.387 m/s2 |

- | During deceleration/acceleration: Changes continuously |

|

Tester Display |

|---|

| Deceleration Sensor |

|

Deceleration Sensor2 |

(d) Check the yaw rate and acceleration sensor (airbag sensor assembly) output value displayed on the Techstream.

OK:

The yaw rate and acceleration sensor (airbag sensor assembly) output value is normal.

| OK |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG |  | REPLACE AIRBAG SENSOR ASSEMBLY |

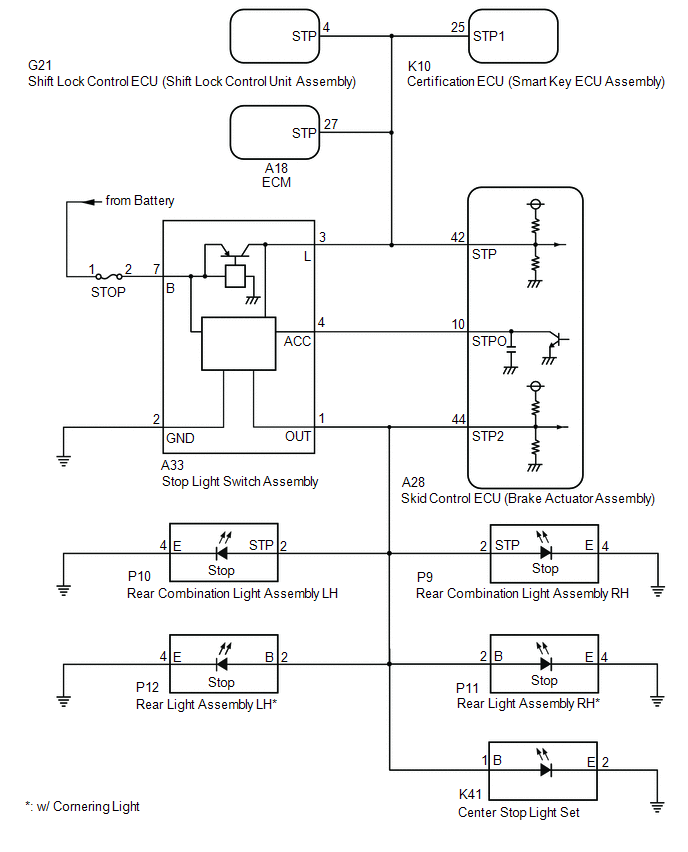

DESCRIPTION

When the skid control ECU (brake actuator assembly) applies the brakes after receiving a brake request signal from the pre-collision system, dynamic radar cruise control system, secondary collision brake system or brake hold control system, the skid control ECU (brake actuator assembly) operates the stop light control relay (stop light switch assembly) to illuminate the stop lights.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

C1380 | Stop Light Relay Malfunction |

Either condition is met:

|

|

|

Vehicle Condition | |||

|---|---|---|---|

|

Pattern 1 | Pattern 2 | ||

|

Diagnosis Condition | The voltage at the +BS terminal is between 10 V or more. |

○ | ○ |

|

Malfunction Status | When the stop light control relay (stop light switch assembly) drive output (STPO) is on, a signal is not input to the STP terminal. |

○ | - |

|

When the stop light control relay (stop light switch assembly) drive output (STPO) is off, the signal at the STP2 terminal is different from the input signal at the STP terminal. |

- | ○ | |

|

Detection Time | 5 seconds or more |

5 seconds or more | |

|

Number of Trips | 1 trip |

1 trip | |

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Click here

PROCEDURE

|

1. | READ VALUE USING TECHSTREAM (BS1 VOLTAGE VALUE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Data List.

Chassis > ABS/VSC/TRAC/EPB > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

BS1 Voltage Value | +BS voltage value |

Min.: 0.00 V, Max.: 20.00 V |

- | Changes in proportion to battery voltage |

|

Tester Display |

|---|

| BS1 Voltage Value |

(d) Take a note of the +BS voltage value.

HINT:

The noted +BS voltage value is used in a later step.

|

| 2. |

CHECK HARNESS AND CONNECTOR (STP2, STPO AND STP TERMINAL) |

| (a) Turn the engine switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-42 (STP) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

|

A28-10 (STPO) - Body ground |

Always | 11 to 14 V |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

|

Result | Proceed to |

|---|---|

|

All terminal voltages are normal |

A |

| Only STP terminal voltage abnormal |

B |

| Only STPO terminal voltage abnormal |

C |

| Only STP2 terminal voltage abnormal |

D |

| STPO terminal and STP2 terminal voltage abnormal |

E |

| B |

| GO TO STEP 6 |

| C |

| GO TO STEP 11 |

| D |

| GO TO STEP 12 |

| E |

| GO TO STEP 22 |

|

| 3. |

PERFORM ACTIVE TEST USING TECHSTREAM (STOP LIGHT RELAY) |

(a) Reconnect the A28 skid control ECU (brake actuator assembly) connector.

(b) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Active Test.

Chassis > ABS/VSC/TRAC/EPB > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Stop Light Relay | Stop light control relay (Stop light switch assembly) |

Relay OFF/ON | Stop lights come on |

|

Tester Display |

|---|

| Stop Light Relay |

OK:

Stop light turns ON/OFF in response to the Techstream operation

| NG |  | GO TO STEP 5 |

|

| 4. |

CHECK FOR DTC |

(a) Clear the DTCs.

Chassis > ABS/VSC/TRAC/EPB > Clear DTCs(b) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Active Test.

Chassis > ABS/VSC/TRAC/EPB > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Stop Light Relay | Stop light control relay (Stop light switch assembly) |

Relay OFF/ON | Stop lights come on |

|

Tester Display |

|---|

| Stop Light Relay |

(c) According to the display on the Techstream, perform the Active Test.

(d) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC/EPB > Trouble Codes|

Result | Proceed to |

|---|---|

|

C1380 is output | A |

|

C1380 is not output | B |

| A |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

| B |

| USE SIMULATION METHOD TO CHECK |

| 5. |

INSPECT BRAKE ACTUATOR ASSEMBLY |

(a) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Active Test.

Chassis > ABS/VSC/TRAC/EPB > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Stop Light Relay | Stop light control relay (Stop light switch assembly) |

Relay OFF/ON | Stop lights come on |

|

Tester Display |

|---|

| Stop Light Relay |

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPLACE BRAKE ACTUATOR ASSEMBLY |

| 6. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - SMART KEY ECU ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the K10 certification ECU (smart key ECU assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-42 (STP) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE SMART KEY ECU ASSEMBLY |

|

| 7. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - ECM) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A18 ECM connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-42 (STP) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE ECM |

|

| 8. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - SHIFT LOCK CONTROL UNIT ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the G21 shift lock control ECU (shift lock control unit assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-42 (STP) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY |

|

| 9. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A33 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - Body ground |

Always | Below 1.5 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 10. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-42 (STP) - A33-3 (L) |

Always | Below 1 Ω |

|

A28-42 (STP) or A33-3 (L) - Body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 11. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A33 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-10 (STPO) - A33-4 (ACC) |

Always | Below 1 Ω |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 12. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - REAR COMBINATION LIGHT ASSEMBLY LH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the P10 rear combination light assembly LH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE REAR COMBINATION LIGHT ASSEMBLY LH |

|

| 13. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - REAR COMBINATION LIGHT ASSEMBLY RH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the P9 rear combination light assembly RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (w/o Cornering Light) | B |

|

NG (w/ Cornering Light) |

C |

| A |

| REPLACE REAR COMBINATION LIGHT ASSEMBLY RH |

| C |

| GO TO STEP 17 |

|

| 14. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - CENTER STOP LIGHT SET) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the K41 center stop light set connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE CENTER STOP LIGHT SET |

|

| 15. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A33 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Always | Below 1.5 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 16. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-1 (OUT) - A28-44 (STP2) |

Always | Below 1 Ω |

|

A33-1 (OUT) or A28-44 (STP2) - Body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 17. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - REAR LIGHT ASSEMBLY LH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the P12 rear light assembly LH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE REAR LIGHT ASSEMBLY LH |

|

| 18. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - REAR LIGHT ASSEMBLY RH) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the P11 rear light assembly RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE REAR LIGHT ASSEMBLY RH |

|

| 19. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - CENTER STOP LIGHT SET) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the K41 center stop light set connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Stop light switch assembly on (Brake pedal depressed) |

(+BS x 0.85) to 14 V* |

|

A28-44 (STP2) - Body ground |

Stop light switch assembly off (Brake pedal released) |

Below 1.5 V |

HINT:

*: The minimum voltage value varies depending on the +BS terminal voltage value. The minimum voltage is 85% or more of the +BS terminal voltage.

| OK |  | REPLACE CENTER STOP LIGHT SET |

|

| 20. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A33 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-44 (STP2) - Body ground |

Always | Below 1.5 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 21. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-1 (OUT) - A28-44 (STP2) |

Always | Below 1 Ω |

|

A33-1 (OUT) or A28-44 (STP2) - Body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 22. |

CHECK STOP LIGHT SWITCH ASSEMBLY POWER SOURCE CIRCUIT |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A33 stop light switch assembly connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-2 (GND) - Body ground |

Always | Below 1 Ω |

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A33-7 (B) - Body ground |

Always | 11 to 14 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 23. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - STOP LIGHT SWITCH ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-10 (STPO) or A33-4 (ACC) - Body ground |

Always | 10 kΩ or higher |

| OK |  | REPLACE STOP LIGHT SWITCH ASSEMBLY |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR |

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS operation.

This DTC is stored when the +BS terminal voltage deviates due to a malfunction in a power supply or charging system circuit such as the battery or alternator circuit, etc.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

|---|---|---|---|

|

C1417 | IG1 Voltage Supply too High |

+BS terminal voltage is more than 16.5 V for 1 second or more. |

|

WIRING DIAGRAM

Refer to DTC C1241.

Click here

CAUTION / NOTICE / HINT

NOTICE:

Click here

PROCEDURE

|

1. | CHECK BATTERY |

(a) Check the battery voltage.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

Positive (+) terminal - Negative (-) terminal |

Engine switch off | 11 to 14 V |

| NG |  | CHECK OR REPLACE CHARGING SYSTEM COMPONENT OR BATTERY |

|

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A28-30 (+BS) - Body ground |

Always | 11 to 14 V |

|

A28-30 (+BS) - A28-46 (GND1) |

Always | 11 to 14 V |

|

A28-36 (IG1) - Body ground |

Engine switch on (IG) |

11 to 14 V |

|

A28-36 (IG1) - A28-46 (GND1) |

Engine switch on (IG) |

11 to 14 V |

| NG |  | REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

|

| 3. |

RECONFIRM DTC |

(a) Turn the engine switch off.

(b) Reconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Clear the DTCs.

Chassis > ABS/VSC/TRAC/EPB > Clear DTCs(d) Turn the engine switch off.

(e) Start the engine.

(f) Perform a road test.

(g) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC/EPB > Trouble Codes|

Result | Proceed to |

|---|---|

|

C1417 is not output | A |

|

C1417 is output | B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Sfi System: Fuel Rail / System Pressure - Too Low (P008700)

DESCRIPTION The high-pressure direct injection fuel system consists of a spill control valve, check valve, fuel relief valve, fuel pressure sensor, fuel pump assembly (for high pressure side) and fuel injector assemblies (for direct injection). The spill control valve adjusts the return volume of hi ...