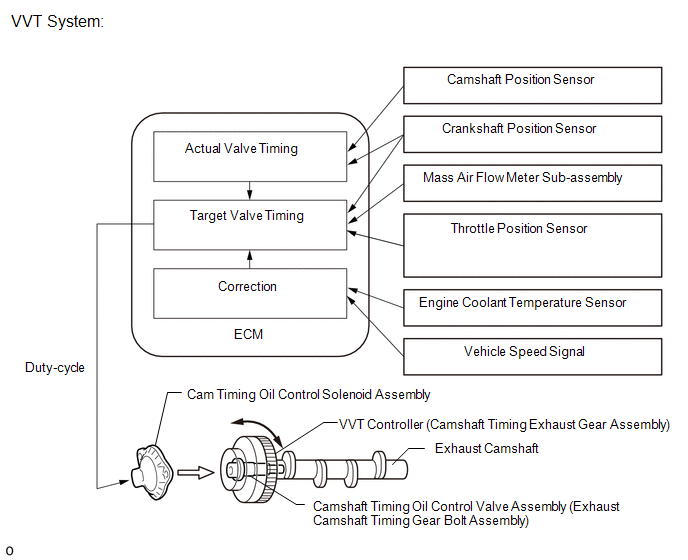

DESCRIPTION The Variable Valve Timing (VVT) system (for exhaust side) adjusts the exhaust valve timing to improve driveability. The engine oil pressure turns the VVT controller (camshaft timing exhaust gear assembly) to adjust the valve timing. The cam timing oil control solenoid assembly operates according to signals received from the ECM to control the position of the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) and supply engine oil. The camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) moves when the ECM applies 12 V to the cam timing oil control solenoid assembly. The ECM changes the energizing time of the cam timing oil control solenoid assembly (duty-cycle) in accordance with the camshaft position, crankshaft position, throttle position, etc.

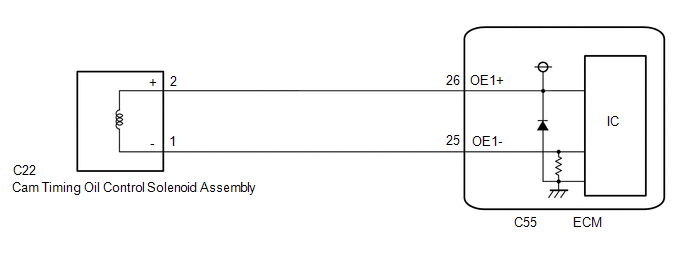

MONITOR DESCRIPTION This DTC is designed to detect an open or short in the cam timing oil control solenoid assembly circuit. If the cam timing oil control solenoid assembly duty-cycle is excessively high or low while the power switch is on (IG) or the engine is running, the ECM will illuminate the MIL and store this DTC. MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS All

TYPICAL MALFUNCTION THRESHOLDS Case 1

CONFIRMATION DRIVING PATTERN HINT:

WIRING DIAGRAM  CAUTION / NOTICE / HINT NOTICE:

HINT: Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred. PROCEDURE

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Clear the DTC after recording the Freeze Frame Data and DTC. Powertrain > Engine > Clear DTCs(e) Turn the power switch off and wait for at least 30 seconds.

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Put the engine in Inspection Mode (Maintenance Mode). Powertrain > Hybrid Control > Utility

(e) Start the engine. (f) Enter the following menus: Powertrain / Engine / Trouble Codes. (g) Read the DTCs. Powertrain > Engine > Trouble Codes

(a) Inspect the cam timing oil control solenoid assembly. Click here

(a) Disconnect the cam timing oil control solenoid assembly connector. (b) Disconnect the ECM connector. (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Sfi System: System Too Lean Bank 1 (P017100,P017200,P017400,P017500,P117000,P117B00)

DESCRIPTION The fuel trim is related to the feedback compensation value, not to the basic injection duration. The fuel trim consists of both the short-term and long-term fuel trims. The short-term fuel trim is fuel compensation that is used to constantly maintain the air fuel ratio at stoichiometric ...