DESCRIPTION Based on the

driving conditions, the ECM regulates the volume of exhaust gas that is

recirculated to each engine cylinder in order to lower the combustion

temperature and reduce NOx emissions. The ECM monitors signals such as

engine speed, engine coolant temperature, electric load, and vehicle

speed. When the EGR permission conditions are met, the ECM controls the

opening of the EGR valve linearly through signals to the EGR step motor. |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Memory |

Note | | P04019C |

Exhaust Gas Recirculation "A" Low / Insufficient Flow |

Change

in intake manifold pressure is small when the EGR valve opened and

closed during fuel cut operation (2 trip detection logic). |

- EGR valve assembly

- EGR passage

- EGR cooler assembly

- Intake system

- Manifold absolute pressure sensor

| Comes on |

DTC stored | SAE Code: P0401 | MONITOR DESCRIPTION

The

ECM monitors the pressure inside the intake manifold while opening and

closing the EGR valve during fuel cut operation. If there is no change

in the manifold absolute pressure sensor value, the ECM interprets this

as a malfunction of the EGR valve assembly, illuminates the MIL and

stores this DTC. MONITOR STRATEGY |

Related DTC | P0401: EGR valve high flow rate/low flow rate | |

Required Sensors/Components (Main) | EGR valve assembly

Manifold absolute pressure sensor | |

Required Sensors/Components (Related) |

Engine coolant temperature sensor | |

Frequency of Operation | Once per driving cycle | |

Duration | Within 5 seconds | |

MIL operation | 2 driving cycles | |

Sequence of operation | None | TYPICAL ENABLING CONDITIONS |

Monitor runs whenever the following DTCs are not stored |

P0010, P1360, P1362, P1364, P1366, P2614 (Motor drive VVT system control module)

P0011 (VVT system - advance) P0012 (VVT system - retard) P0013 (Exhaust VVT oil control solenoid)

P0014 (Exhaust VVT system - advance) P0015 (Exhaust VVT system - retard)

P0016 (VVT system - misalignment) P0017 (Exhaust VVT system - misalignment)

P0031, P0032, P101D (Air fuel ratio sensor (sensor 1) heater) P0101, P0102, P0103 (Mass air flow meter)

P0106, P0107, P0108 (Manifold absolute pressure) P0111, P0112, P0113 (Intake air temperature sensor)

P0116, P0117, P0118 (Engine coolant temperature sensor) P0121, P0122, P0123, P0222, P0223, P2135 (Throttle position sensor)

P0125 (Insufficient coolant temperature for closed loop fuel control)

P014C, P014D, P015A, P015B, P2195, P2196, P2237, P2238, P2239, P2252, P2253 (Air fuel ratio sensor (sensor 1))

P0171, P0172 (Fuel system) P0327, P0328 (Knock control sensor)

P0335, P0337, P0338 (Crankshaft position sensor) P0340, P0342, P0343 (Camshaft position sensor)

P0365, P0367, P0368 (Exhaust camshaft position sensor) P0489, P0490 (EGR control circuit)

P0657, P2102, P2103, P2111, P2112, P2119 (Throttle actuator) P106A (Evaporative emission control system pressure sensor - manifold pressure sensor correlation)

P11EA, P11EC, P11ED, P11EE, P11EF, P219A, P219C, P219D, P219E, P219F (Air-fuel ratio imbalance)

P2228, P2229 (Atmospheric pressure sensor) | |

Time after engine started | 3 seconds or more | |

Time after engine fuel cut | 2597 msec or more | |

Engine speed | 950 to 1600 rpm | |

Vehicle speed | 20 km/h (13 mph) or more | |

Engine coolant temperature |

75°C (167°F) or higher | | Auxiliary battery voltage |

11 V or higher | | Intake air temperature |

-10°C (14°F) or higher | | Atmospheric pressure |

76 kPa(abs) [11 psi(abs)] or higher | TYPICAL MALFUNCTION THRESHOLDS |

Manifold pressure change | Less than 1.72 kPa [0.25 psi] | |

At engine speed | 2400 rpm | MONITOR RESULT

Refer to detailed information in Checking Monitor Status. Click here

P0401: Exhaust Gas Recirculation / VVT / EGR FLOW INSUFFICIENCY |

Monitor ID | Test ID |

Scaling | Unit |

Description | | $31 |

$BD | Multiply by 0.01 |

kPa | Delta manifold absolute pressure | CONFIRMATION DRIVING PATTERN

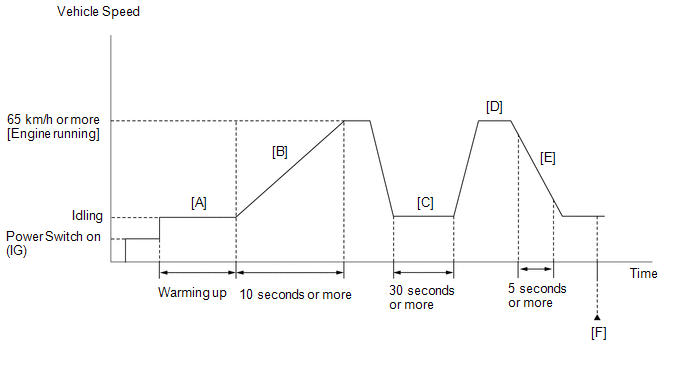

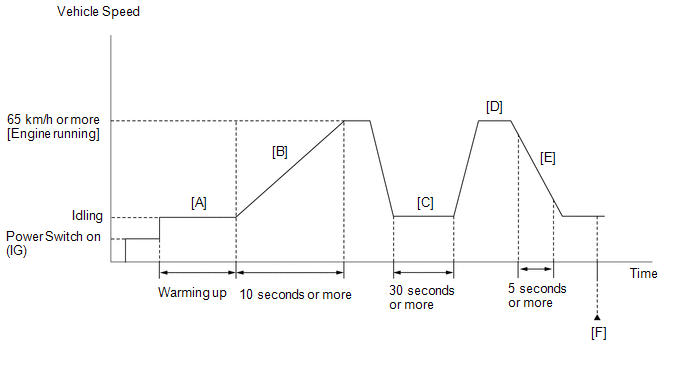

HINT:

- After repair has been completed, clear the DTC and then check that the

vehicle has returned to normal by performing the following All Readiness

check procedure.

Click here

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Put the engine in Inspection Mode (Maintenance Mode).

Click here

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [A].

- With the engine running, accelerate the vehicle to 65 km/h (40 mph) or

more by depressing the accelerator pedal for at least 10 seconds [B].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

When accelerating the vehicle, depress the accelerator pedal more than normal to start the engine.

- Idle the engine for 30 seconds or more [C].

- With the shift lever in S and the engine running, accelerate the vehicle to 65 km/h (40 mph) or more [D].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

If the engine stops, further depress the accelerator pedal to restart the engine.

- Perform the fuel cut operation for 5 seconds or more, with the accelerator pedal fully released [E].

- Enter the following menus: Powertrain / Engine / Monitor / Current Monitor [F].

- Check that Exhaust Gas Recirculation/VVT / Current is Complete.

HINT:

If the monitor item Exhaust Gas Recirculation/VVT / Current is Incomplete, perform the driving pattern again.

- Enter the following menus: Powertrain / Engine / Monitor / Current Monitor / Exhaust Gas Recirculation/VVT / Details.

- Check the Details (EGR FLOW INSUFFICIENCY).

HINT:

Make sure that the value is between MIN and MAX.

- If the monitor item Exhaust Gas Recirculation/VVT / Current is still Incomplete, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Trouble Codes.

- Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC P04019C.

- Check the DTC judgment result.

|

Techstream Display |

Description |

|

NORMAL |

- DTC judgment completed

- System normal

|

|

ABNORMAL |

- DTC judgment completed

- System abnormal

|

|

INCOMPLETE |

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

HINT:

WIRING DIAGRAM Refer to DTC P040318. Click here

CAUTION / NOTICE / HINT

NOTICE:

HINT:

- By using the Control the EGR Step Position Active Test, the operation of the EGR valve can be checked.

- If the EGR valve is normal and is opened using the Active Test, the Data List value changes as follows.

|

Data List Item |

Change in Data List when Number of Steps is Increased Using Control the EGR Step Position Active Test

|

|

Intake Manifold Absolute Pressure |

Pressure rises |

- Read Freeze Frame Data using the Techstream. The ECM records vehicle and

driving condition information as Freeze Frame Data the moment a DTC is

stored. When troubleshooting, Freeze Frame Data can help determine if

the vehicle was moving or stationary, if the engine was warmed up or

not, if the air fuel ratio was lean or rich, and other data from the

time the malfunction occurred.

PROCEDURE |

1. | CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P04019C) |

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG).

(c) Turn the Techstream on. (d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read the DTCs. Powertrain > Engine > Trouble Codes

|

Result | Proceed to | |

DTC P04019C is output |

A | | DTC P04019C and other DTCs are output |

B | HINT: If any DTCs other than P04019C are output, troubleshoot those DTCs first.

| B |

| GO TO DTC CHART |

|

A |

| |

| 2. |

READ VALUE USING TECHSTREAM (INTAKE MANIFOLD ABSOLUTE PRESSURE) |

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG).

(c) Turn the Techstream on. (d) Enter the following menus: Powertrain / Engine / Data List / Intake Manifold Absolute Pressure. Powertrain > Engine > Data List

|

Tester Display | | Intake Manifold Absolute Pressure |

(e) Read the value of Intake Manifold Absolute Pressure. Standard: |

Techstream Display | Specified Condition | |

Intake Manifold Absolute Pressure |

80 to 110 kPa (11.6 to 15.95 psi) |

| NG |

| REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR |

|

OK |

| |

| 3. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE EGR STEP POSITION) |

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG).

(c) Turn the Techstream on. (d) Put the engine in Inspection Mode (Maintenance Mode). Powertrain > Hybrid Control > Utility

|

Tester Display | | Inspection Mode |

(e) Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher.

HINT: The A/C switch and all accessories should be off. (f)

Enter the following menus: Powertrain / Engine / Active Test / Control

the EGR Step Position / Data List / Intake Manifold Absolute Pressure,

Coolant Temperature and Engine Independent. Powertrain > Engine > Active Test

|

Active Test Display | |

Control the EGR Step Position |

|

Data List Display | |

Intake Manifold Absolute Pressure | |

Coolant Temperature | |

Engine Independent | (g)

According to the display on the Techstream, compare the values of Data

List item Intake Manifold Absolute Pressure before and while performing

the Active Test.

NOTICE:

- Make sure that the value of Data List item Engine Independent is "Operate" while performing the Active Test.

- Do not leave the EGR valve open for 10 seconds or more during the Active Test.

- Be sure to return the EGR valve to step 0 when the Active Test is completed.

- Do not open the EGR valve 30 steps or more during the Active Test.

Standard: The value of Intake Manifold Absolute Pressure changes according to the EGR valve step set by the Active Test. |

Data List | Control the EGR Step Position (Active Test) | |

Before Active Test (Engine idling) |

0 Steps | 0 to 30 Steps

(Engine idling) | |

Intake Manifold Absolute Pressure |

20 to 40 kPa (2.9 to 5.8 psi) |

(EGR valve is fully closed) |

Intake Manifold Absolute Pressure value is at least +10 kPa (1.45 psi) higher than when EGR valve is fully closed |

HINT:

- If the value of Data List item Engine Independent is "Not Opr" when the

engine is idling, charge control is being performed. Perform the Active

Test after charge control is complete ("Operate" is displayed).

- While performing the Active Test, if the increase in the value of Intake

Manifold Absolute Pressure is small, the EGR valve assembly may be

malfunctioning.

- Even if the EGR valve assembly is malfunctioning, rough idling or an

increase in the value of Intake Manifold Absolute Pressure may occur

while performing the Active Test. However, the amount that the value of

Intake Manifold Absolute Pressure increases will be smaller than normal.

|

Result | Proceed to | |

Before

performing the Active Test (while the engine is idling), the value of

Intake Manifold Absolute Pressure is not between 20 to 40 kPa (2.9 to

5.8 psi). | A | |

When

performing the Active Test to change the EGR valve step between 0 (EGR

valve fully closed) and 30, the value of Intake Manifold Absolute

Pressure changes less than 10 kPa (1.45 psi). |

B | | Other than above |

C |

| B |

| GO TO STEP 6 |

| C |

| GO TO STEP 12 |

|

A |

| |

(a) Check the intake system for vacuum leaks.

Click here  OK: No leaks from intake system.

HINT: Perform "Inspection After Repair" after repairing or replacing the intake system.

Click here

| NG |

| REPAIR OR REPLACE INTAKE SYSTEM |

|

OK |

| |

| 5. |

INSPECT EGR VALVE ASSEMBLY | (a) Remove the EGR valve assembly.

Click here  (b) Check if the EGR valve is stuck open.

OK: EGR valve is tightly closed. HINT: Perform "Inspection After Repair" after replacing the EGR valve assembly.

Click here

| OK |

| REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR |

| NG |

| REPLACE EGR VALVE ASSEMBLY |

| 6. |

REPLACE EGR VALVE ASSEMBLY | (a) Replace the EGR valve assembly.

Click here  HINT: Perform "Inspection After Repair" after replacing the EGR valve assembly.

Click here

|

NEXT |

| |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Clear the DTCs. Powertrain > Engine > Clear DTCs

(e) Turn the power switch off and wait for at least 30 seconds.

|

NEXT |

| |

| 8. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P04019C) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Trouble Codes. (c) Read the DTCs. Powertrain > Engine > Trouble Codes

|

Result | Proceed to | |

DTCs are not output | A | |

DTC P04019C is output |

B |

| A |

| END |

|

B |

| |

| 9. |

REPLACE EGR COOLER ASSEMBLY | (a) Replace the EGR cooler assembly.

Click here

HINT:

- If any of the EGR system related pipes (EGR pipe, exhaust manifold,

etc.) are cracked, damaged or clogged, replace them as necessary.

- Perform "Inspection After Repair" after replacing the EGR system.

Click here

|

NEXT |

| |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Clear the DTCs. Powertrain > Engine > Clear DTCs

(e) Turn the power switch off and wait for at least 30 seconds.

|

NEXT |

| |

| 11. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P04019C) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Trouble Codes. (c) Read the DTCs. Powertrain > Engine > Trouble Codes

OK: DTCs are not output.

| NEXT |  |

END | (a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Clear the DTCs. Powertrain > Engine > Clear DTCs

(e) Turn the power switch off and wait for at least 30 seconds.

|

NEXT |

| |

| 13. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P04019C) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Trouble Codes. (c) Read the DTCs. Powertrain > Engine > Trouble Codes

|

Result | Proceed to | |

DTCs are not output | A | |

DTC P04019C is output |

B | HINT: Perform "Inspection After Repair" after replacing the EGR valve assembly.

Click here

| A |

| END |

| B |

| REPLACE EGR VALVE ASSEMBLY | |