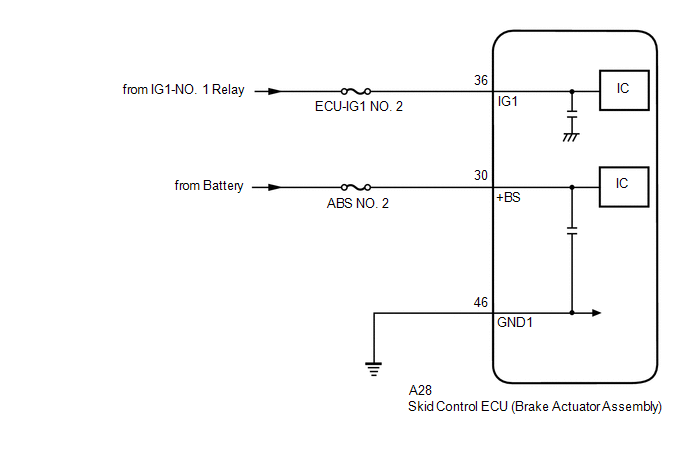

DESCRIPTION If a

malfunction is detected in the power supply circuit, the skid control

ECU (brake actuator assembly) stores this DTC and the fail-safe function

prohibits ABS operation. This DTC is stored when the +BS terminal

voltage meets one of the DTC detection conditions due to a malfunction

in the power supply or charging circuit such as the battery or

alternator circuit, etc. The DTC is cleared when the +BS terminal

voltage returns to normal. |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area | |

C1241 | Low or High Power Supply Voltage |

Any of the following is detected:

- The vehicle speed is 6 km/h (4 mph) or more and the +BS terminal voltage

(soft low voltage) is less than 9.6 V for 1 second or more.

- The vehicle speed is 6 km/h (4 mph) or more and the +BS terminal voltage

(hard low voltage) is less than 6.9 V for 1 second or more.

- The vehicle speed is 15 km/h (9 mph) or more, the +BS terminal voltage

is 9.6 V or more, the skid control ECU (brake actuator assembly) turns

on more than one valve at the same time within a short period of time

and the valve relay supply voltage drop exceeds the threshold.*

- The +BS terminal voltage is less than 6.7 V and the skid control ECU

(brake actuator assembly) judges that power supply voltage is abnormal

for 0.06 seconds or more.

|

- ABS NO. 2 fuse

- Battery

- Charging system

- Power source circuit

- Ground circuit

- Internal power supply circuit of the skid control ECU (brake actuator assembly)

| *:

The skid control ECU (brake actuator assembly) monitors the resistance

of the power source line at the +BS terminal. A malfunction is detected

when an abnormality occurs in the +BS terminal wire harness or its

connection and the skid control ECU (brake actuator assembly) determines

that the wiring resistance at the +BS terminal exceeds the standard

resistance. DTC Detection Conditions: C1241 | |

Vehicle Condition | |

Pattern 1 | Pattern 2 |

Pattern 3 | Pattern 4 | |

Diagnosis Condition | The vehicle speed is 6 km/h (4 mph) or more. |

○ | ○ |

- | - | |

The vehicle speed is 15 km/h (9 mph) or more and the +BS terminal voltage is 9.6 V or more. |

- | - |

○ | - | |

The +BS terminal voltage is less than 6.7 V. |

- | - |

- | ○ | |

Malfunction Status | The +BS terminal voltage (soft low voltage) is less than 9.6 V. |

○ | - |

- | - | |

The +BS terminal voltage (hard low voltage) is less than 6.9 V. |

- | ○ |

- | - | |

The

skid control ECU (brake actuator assembly) turns on more than one valve

at the same time within a short period of time and the valve relay

supply voltage drop exceeds the threshold.* |

- | - |

○ | - | |

The skid control ECU (brake actuator assembly) judges that power supply voltage is abnormal. |

- | - |

- | ○ | |

Detection Time | 1 second or more |

1 second or more | - |

0.06 seconds or more | |

Number of Trips | 1 trip |

1 trip | 1 trip |

1 trip | *:

The skid control ECU (brake actuator assembly) monitors the resistance

of the power source line at the +BS terminal. A malfunction is detected

when an abnormality occurs in the +BS terminal wire harness or its

connection and the skid control ECU (brake actuator assembly) determines

that the wiring resistance at the +BS terminal exceeds the standard

resistance. HINT: DTC will be output when conditions for either of the patterns in the table above are met. WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the skid control ECU (brake actuator assembly), perform

system variant learning and acceleration sensor zero point calibration.

Click here

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE (a) Check the battery voltage.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

Positive (+) terminal - Negative (-) terminal |

Engine switch off | 11 to 14 V |

| NG |

| CHECK OR REPLACE CHARGING SYSTEM COMPONENT OR BATTERY |

|

OK |

| |

| 2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

| (a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK: The connector is securely connected. |

|

|

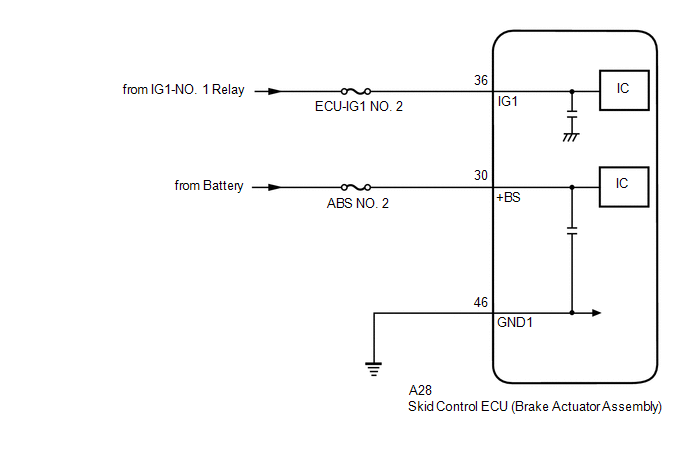

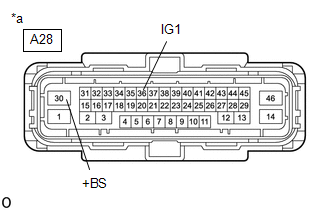

*a | Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly)) | | |

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (d) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

A28-30 (+BS) - Body ground |

Always | 11 to 14 V | |

A28-36 (IG1) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

|

OK |

| |

| 3. |

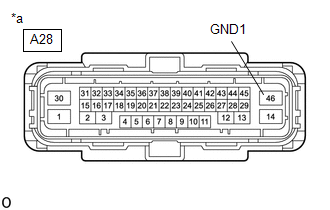

CHECK HARNESS AND CONNECTOR (GND1 TERMINAL) |

| (a) Turn the engine switch off. |

|

|

*a | Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly)) | | |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A28-46 (GND1) - Body ground |

Always | Below 1 Ω |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (GND1 CIRCUIT) |

|

OK |

| |

(a) Reconnect the A28 skid control ECU (brake actuator assembly) connector.

(b) Clear the DTCs. Chassis > ABS/VSC/TRAC/EPB > Clear DTCs (c) Turn the engine switch off.

(d) Start the engine. (e) Perform a road test. (f) Check if the same DTC is output. Chassis > ABS/VSC/TRAC/EPB > Trouble Codes

|

Result | Proceed to | |

C1241 is not output | A | |

C1241 is output | B |

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE ACTUATOR ASSEMBLY | |