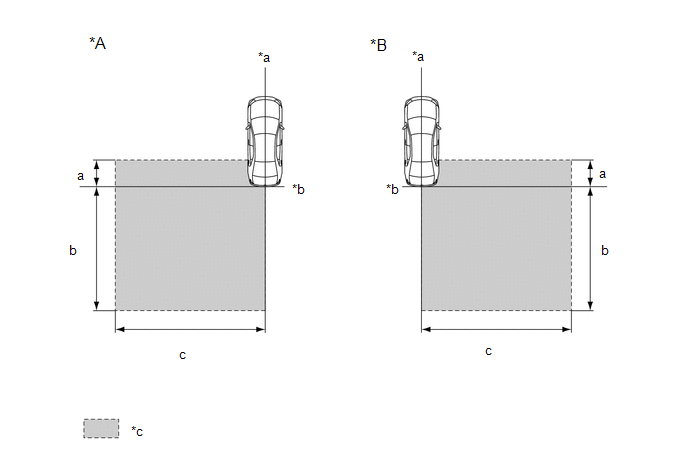

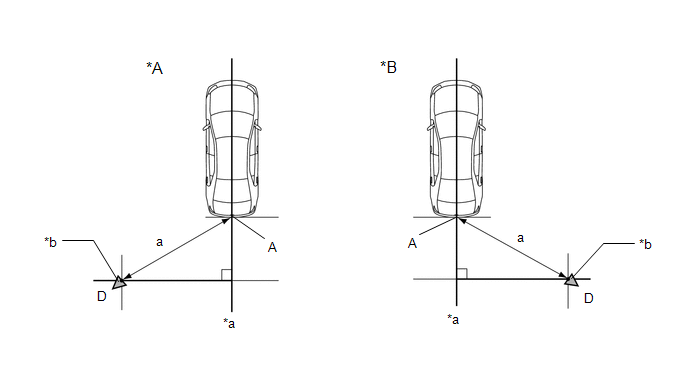

ADJUSTMENT PROCEDURE 1. PERFORM BLIND SPOT MONITOR BEAM AXIS CONFIRMATION HINT: The blind spot monitor beam axis confirmation is performed to confirm whether the sensor's beam axis is correct, and perform adjustment of the beam axis by using reflector. (a) When performing the blind spot monitor beam axis confirmation, move the vehicle to a place where the space shown in the illustration can be secured.

Standard:

NOTICE:

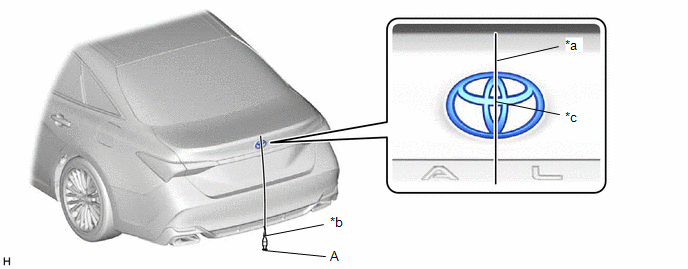

(b) Place the reflector. (1) Hang a weight with a pointed tip from the center of the rear emblem, and mark the rear center point of the vehicle (point A) on the ground.

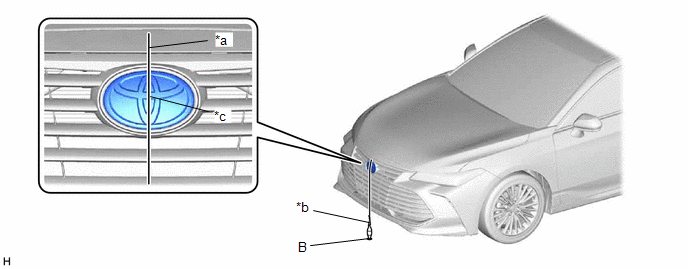

HINT: Lightly flick the string with your fingers several times to confirm that the string is aligned with mark A. (2) Hang a weight with a pointed tip from the center of the radiator grille (or front panel) emblem, and mark the front center point of the vehicle (point B) on the ground.

HINT: Lightly flick the string with your fingers several times to confirm that the string is aligned with mark B.

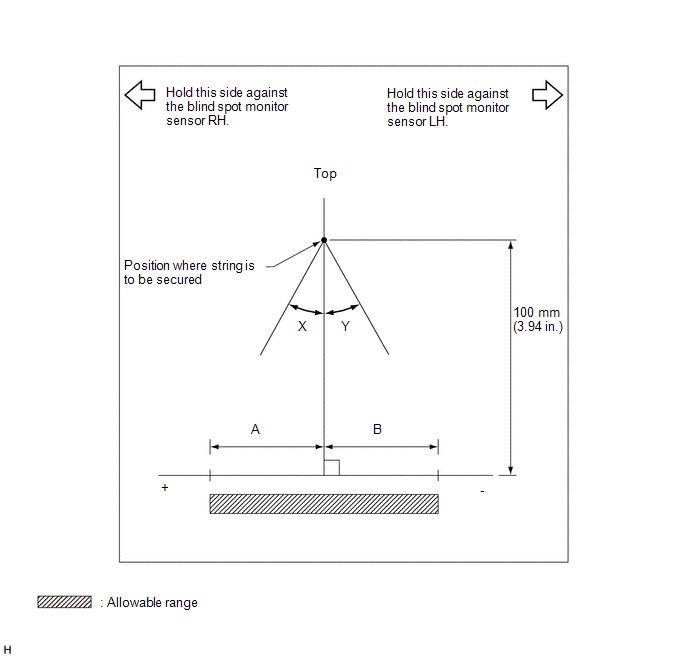

(4) Enlarge and print out the poster shown in the illustration.

Standard:

(7) Set the reflector at the point D shown in the illustration below. SST: 09870-60000 09870-60010 SST: 09870-60040

Standard:

NOTICE:

(c) Perform the blind spot monitor beam axis display. (1) Connect the GTS to the DLC3. (2) Turn the engine switch on (IG). (3) Turn the blind spot monitor system on. (4) Turn the GTS on. (5) Enter the following menus: Body Electrical / Blind Spot Monitor Master or Blind Spot Monitor Slave / Utility / BSM Master Beam Axis Display or BSM Slave Beam Axis Display. HINT: The master beam is on the RH side and the slave beam is on the LH side. Body Electrical > Blind Spot Monitor Master > Utility

(6) Check the results displayed for the BSM beam axis display. Allowable Range:

HINT: If the displayed results are outside the permissible range, the following are possible causes. Therefore, implement countermeasures, check the blind spot monitor beam axis and perform the procedure again.

(d) Perform the blind spot monitor beam axis adjustment. (1) Enter the following menus: Body Electrical / Blind Spot Monitor Master or Blind Spot Monitor Slave / Utility / BSM Master Beam Axis Adjustment or BSM Slave Beam Axis Adjustment. Body Electrical > Blind Spot Monitor Master > Utility

HINT: When values on the axis display are in the allowable range, performing this adjustment compensates for any deviation from the normal value. 2. PERFORM BLIND SPOT MONITOR SENSOR INSTALLATION CONDITION INSPECTION NOTICE:

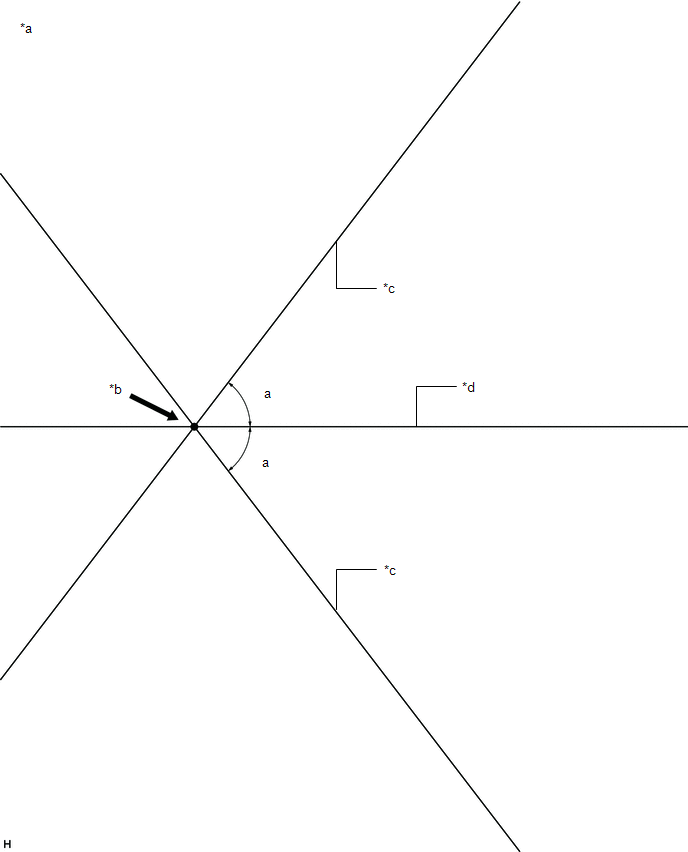

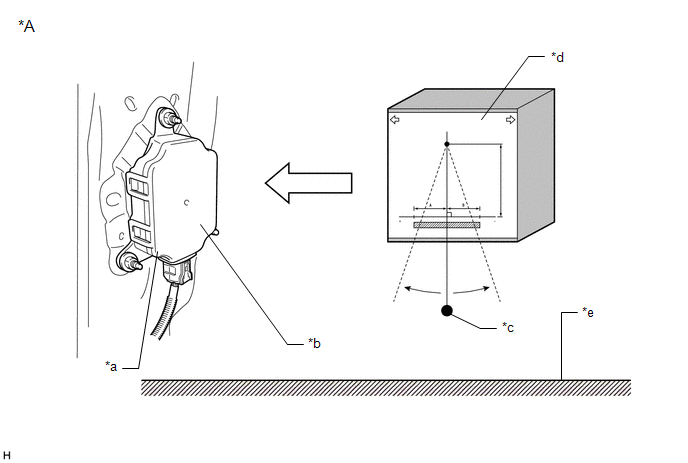

HINT: The blind spot monitor sensor installation condition inspection is performed to confirm whether the sensor is perpendicular to the floor surface (+/-5°) by using a jig, and that the sensor is 46 to 54° from the line parallel to the vehicle center line. (a) Remove the rear bumper assembly. Click here (b) Attach a jig similar to the one shown in the illustration to the outward facing surface of the blind spot monitor sensor and check that the measurement or angle is within the allowable range to confirm that the blind spot monitor sensor is perpendicular to the floor surface (+/-5°).

Standard:

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Fuel Injector(for Direct Injection): Removal

REMOVAL CAUTION / NOTICE / HINT The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel injector assembly removal/installation are shown below. Necessary Procedures After Parts Removed/In ...