REMOVAL CAUTION / NOTICE / HINT

The

necessary procedures (adjustment, calibration, initialization or

registration) that must be performed after parts are removed and

installed, or replaced during brake actuator assembly

removal/installation are shown below. Necessary Procedures After Parts Removed/Installed/Replaced |

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link | |

*: When performing learning using the Techstream.

Click here  | |

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

| |

Pre-collision system | |

Intelligent Clearance Sonar System* | |

Lighting System (for Gasoline Model with Cornering Light) | |

Memorize steering angle neutral point |

Parking assist monitor system |

| |

Panoramic View Monitor System |

| |

Replacement of brake actuator assembly |

Perform system variant learning and acceleration sensor zero point calibration |

- VSC is disabled or malfunctions

- DTCs are output

- Slip indicator light illuminates

- ABS warning light illuminates

|

| |

Operate the electric parking brake switch (electric parking brake switch assembly) |

Parking brake indicator light blinks when the engine switch is first turned on (IG) |

| PROCEDURE

1. PRECAUTION NOTICE: After

turning the engine switch off, waiting time may be required before

disconnecting the cable from the negative (-) battery terminal.

Therefore, make sure to read the disconnecting the cable from the

negative (-) battery terminal notices before proceeding with work. Click here

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Click here  NOTICE: When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

Click here  3. DRAIN BRAKE FLUID

NOTICE: If brake fluid leaks onto any painted surface, immediately wash it off.

4. REMOVE FRONT WHEEL RH Click here

5. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY Click here

6. REMOVE FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY

| (a) Disconnect the connector. | |

(b) Disengage the 2 clamps and separate the wire harness.

| (c) Remove the 6 bolts, 4 nuts and front center upper suspension brace sub-assembly. |

|

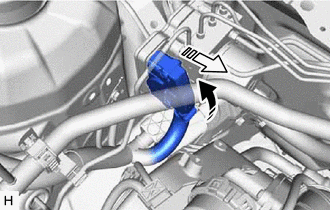

7. REMOVE BRAKE ACTUATOR WITH BRACKET (a) Release the lock lever and disconnect the connector from the brake actuator assembly.

| Release the lock lever |

|

Disconnect the connector | NOTICE:

Be careful not to allow any brake fluid to enter the connector.

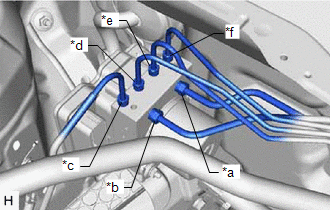

| (b) Use tags or make a memo to identify the places to reconnect the brake lines. |

|

|

*a | From 1st Chamber of Brake Master Cylinder Sub-assembly | |

*b | From 2nd Chamber of Brake Master Cylinder Sub-assembly | |

*c | To Front Wheel Cylinder Assembly RH | |

*d | To Rear Wheel Cylinder Assembly LH | |

*e | To Rear Wheel Cylinder Assembly RH | |

*f | To Front Wheel Cylinder Assembly LH | | |

| (c) Using a union nut wrench, disconnect the 6 brake lines from the brake actuator assembly.

NOTICE:

- Do not kink or damage the brake lines.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

| |

| (d) Using a union nut wrench, disconnect the front No. 3 brake tube while holding the front flexible hose with a wrench.

NOTICE:

- Do not kink or damage the front No. 3 brake tube.

- Do not allow any foreign matter such as dirt or dust to enter the front No. 3 brake tube from the connecting parts.

| |

| (e) Disengage the clamp and separate the front No. 3 brake tube.

NOTICE: Do not kink or damage the front No. 3 brake tube. |

|

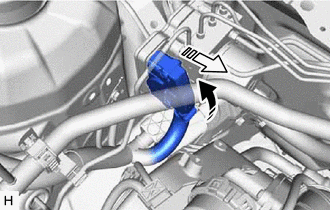

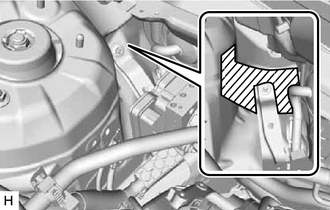

| (f) Move aside the front No. 3 brake tube as shown in the illustration.

NOTICE: Do not apply excessive force to the front No. 3 brake tube. |

|

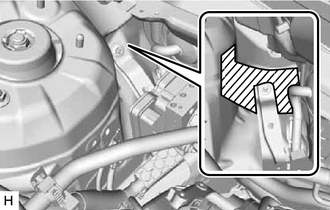

| (g) Disengage the clamp and remove the brake tube clamp. |

|

(h) Apply protective tape to the vehicle body as shown in the illustration.

|

Protective Tape |

| (i) Remove the 2 bolts. HINT: Insert the tool from the bottom of the vehicle. |

|

| (j) Remove the nut and brake actuator with bracket.

NOTICE:

- Do not kink or damage the brake lines.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

- Be careful not to allow any brake fluid to enter the connector.

- Do not hold the brake actuator assembly by the connector.

- Do not drop the brake actuator with bracket when carrying it.

HINT: Remove the brake actuator with bracket while avoiding the brake lines. |

|

8. REMOVE BRAKE ACTUATOR ASSEMBLY

(b) Remove the bolt and brake actuator assembly from the brake actuator bracket assembly.

NOTICE:

- Do not hold the brake actuator assembly by the connector.

- Do not drop the brake actuator assembly when carrying it.

9. REMOVE NO. 1 BRAKE ACTUATOR CASE COLLAR

| (a) Remove the No. 1 brake actuator case collar from the brake actuator bracket cushion. |

|

10. REMOVE BRAKE ACTUATOR BOLT CUSHION

| (a) Remove the brake actuator bolt cushion from the brake actuator bracket assembly. |

| |