DTC SUMMARY |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Memory |

Note | | P045011 |

Evaporative Emission System Pressure Sensor/Switch Circuit Short to Ground |

EVAP pressure is less than 42.110 kPa(abs) [6.106 psi(abs)] for 0.5 seconds or more. |

| Comes on |

DTC stored | SAE Code: P0452 | |

P045015 | Evaporative Emission System Pressure Sensor/Switch Circuit Short to Battery or Open |

EVAP pressure is higher than 123.761 kPa(abs) [17.945 psi(abs)] for 0.5 seconds or more. |

| Comes on |

DTC stored | SAE Code: P0453 | |

P04502F | Evaporative Emission System Pressure Sensor/Switch Signal Erratic |

Canister pressure sensor output voltage fluctuates frequently for a certain amount of time. |

| Comes on |

DTC stored | SAE Code: P0451 | |

DTC No. | Monitoring Item |

Detection Timing | Detection Logic |

SAE Code | | P045011 |

Canister pressure sensor low input |

- Power switch on (IG)

- EVAP monitoring (power switch off)

| 1 trip |

P0452 | | P045015 |

Canister pressure sensor high input |

- Power switch on (IG)

- EVAP monitoring (power switch off)

| 1 trip |

P0453 | | P04502F |

Canister pressure sensor abnormal voltage fluctuation (Noise monitor) |

- EVAP monitoring (power switch off)

- Engine running

| 2 trip |

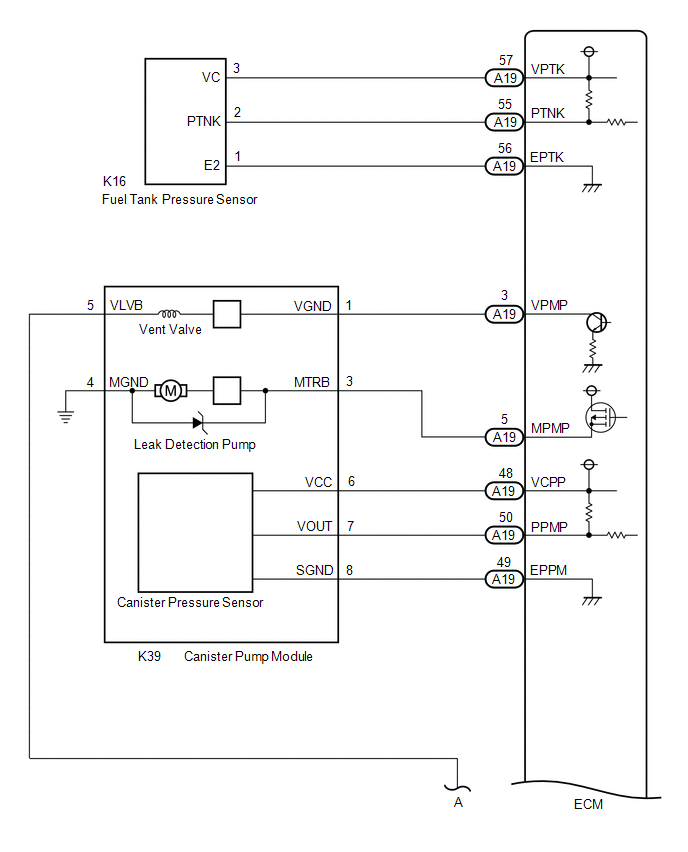

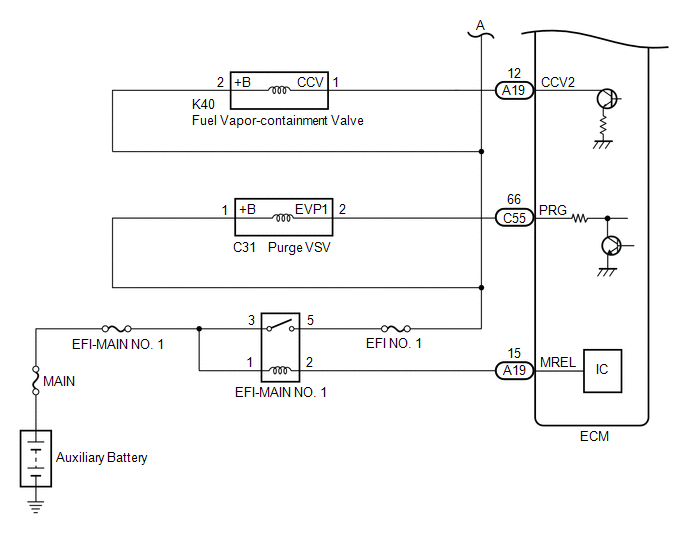

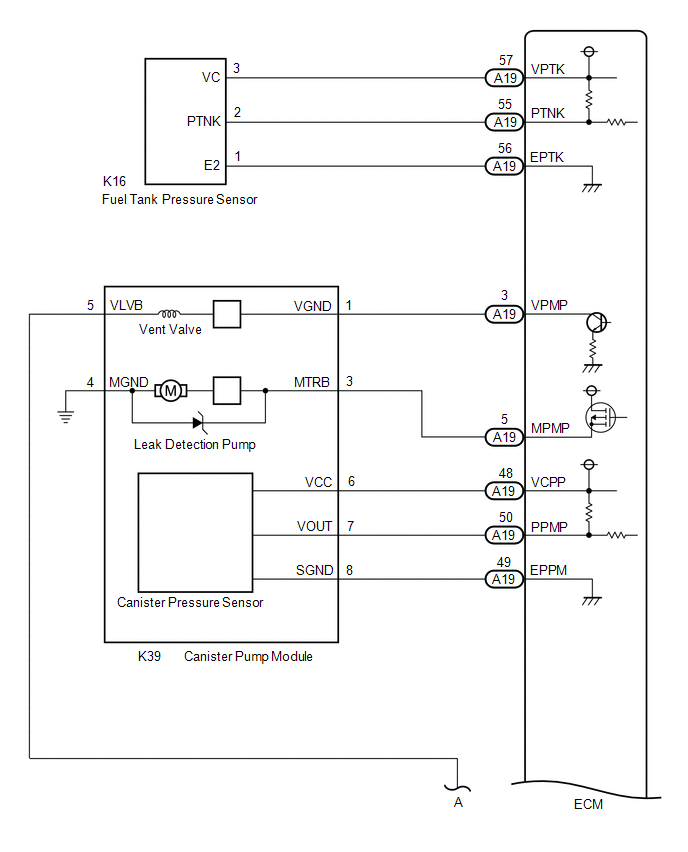

P0451 | HINT: The canister pressure sensor is built into the canister pump module. DESCRIPTION

Refer to EVAP (Evaporative Emission) System. Click here

MONITOR DESCRIPTION

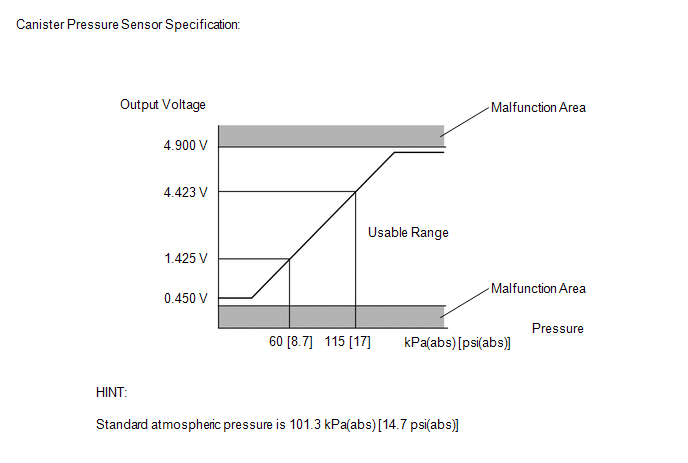

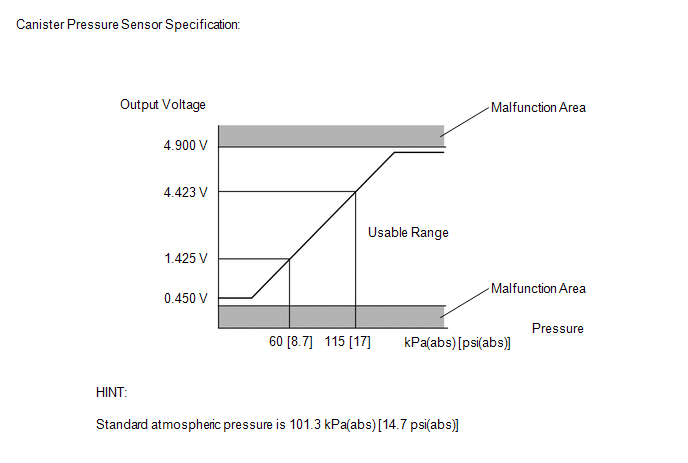

- DTC P045011: Canister pressure sensor voltage low

If the canister pressure sensor output voltage

(pressure) is less than 0.45 V: 42.110 kPa(abs) [6.106 psi(abs)], the

ECM interprets this as an open or short circuit in the canister pressure

sensor or its circuit, and stops the EVAP system monitor. If any

deterioration has occurred, the ECM will illuminate the MIL and store

this DTC (1 trip detection logic).

- DTC P045015: Canister pressure sensor voltage high

If the canister pressure sensor output voltage

(pressure) is higher than 4.9 V: 123.761 kPa(abs) [17.945 psi(abs)], the

ECM interprets this as an open or short circuit in the canister

pressure sensor or its circuit, and stops the EVAP system monitor. If

any deterioration has occurred, the ECM will illuminate the MIL and

store this DTC (1 trip detection logic).

- DTC P04502F: Canister pressure sensor abnormal voltage fluctuation (Noise monitor)

If the canister pressure sensor output voltage

fluctuates rapidly for 10 seconds, the ECM stops the EVAP system

monitor. The ECM interprets this as the canister pressure sensor voltage

fluctuating, and stops the EVAP system monitor. The ECM then

illuminates the MIL and stores this DTC (2 trip detection logic).

MONITOR STRATEGY |

Required Sensors/Components (Main) | Canister pump module | |

Required Sensors/Components (Related) |

- | | Frequency of Operation |

Continuous | | Duration |

0.5 seconds: P0452 and P0453 Less than 15 seconds: P0451 | |

MIL Operation | Immediate: P0452 and P0453

2 driving cycles: P0451 | | Sequence of Operation |

None | TYPICAL ENABLING CONDITIONS P0451 |

Atmospheric pressure | 70 kPa(abs) [10.2 psi(abs)] or higher, and less than 110 kPa(abs) [16 psi(abs)] | |

Auxiliary battery voltage | 10.5 V or higher | |

Intake air temperature | 4.4°C (39.9°F) or higher, and less than 50°C (122°F) | |

Canister pressure sensor malfunction (P0452, P0453) |

Not detected | | Either of the following conditions is met |

A or B | | A. Power switch |

On (READY) | | B. Time after key-off |

5, 7 or 9.5 hours | P0452 and P0453 |

Monitor runs whenever the following DTCs are not stored |

None | | Both of the following conditions are met |

- | | Either of the following conditions is met |

(a) or (b) | | (a) Power switch |

On (IG) | | (b) Soak timer |

On | | Auxiliary battery voltage |

8 V or higher | TYPICAL MALFUNCTION THRESHOLDS P0451: Canister Pressure Sensor Noise Monitoring |

Frequency that EVAP pressure change 0.3 kPa [0.04 psi] or higher |

10 times or more in 10 seconds | P0452: Canister Pressure Sensor Low Voltage |

EVAP system pressure sensor voltage (EVAP pressure) |

Less than 0.45 V [Less than 42.110 kPa(abs) (6.106 psi(abs))] | P0453: Canister Pressure Sensor High Voltage |

EVAP system pressure sensor voltage (EVAP pressure) |

Higher than 4.9 V [Higher than 123.761 kPa(abs) (17.945 psi(abs))] | CONFIRMATION DRIVING PATTERN

NOTICE:

- The Evaporative System Check (Automatic Mode) consists of 9 steps

performed automatically by the Techstream. It takes a maximum of

approximately 40 minutes.

- Do not perform the Evaporative System Check when the fuel tank is more

than 90% full because the cut-off valve may be closed, making the fuel

tank leak check unavailable.

- Do not start the engine during this operation.

- When the temperature of the fuel is 35°C (95°F) or higher, a large

amount of vapor will from and any check result will be inaccurate. When

performing the Evaporative System Check, keep the fuel temperature less

than 35°C (95°F).

HINT:

- After repair has been completed, clear the DTC and then check that the

vehicle has returned to normal by performing the following All Readiness

check procedure.

Click here

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG) [A].

- Turn the Techstream on.

- Enter the following menus: Powertrain / Engine / Data List / Intake Air Temperature.

- Check that the intake air temperature is between 4.4 and 50°C (39.9 and 122°F) [B].

- Enter the following menus: Powertrain / Engine / Utility / Evaporative System Check / Automatic Mode [C].

- After the Evaporative System Check is completed, check for All Readiness

by entering the following menus: Powertrain / Engine / Utility / All

Readiness.

- Input the DTC: P045011, P045015 or P04502F.

- Check the DTC judgment result.

|

Techstream Display |

Description |

|

NORMAL |

- DTC judgment completed

- System normal

|

|

ABNORMAL |

- DTC judgment completed

- System abnormal

|

|

INCOMPLETE |

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

HINT:

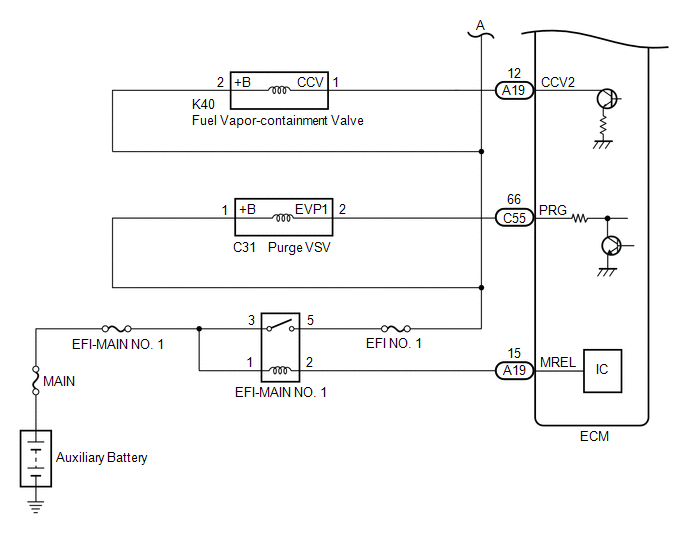

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE |

1. | CONFIRM DTC AND EVAP PRESSURE |

(a) Connect the Techstream to the DLC3. (b) Turn the power switch on (IG) (do not start the engine).

(c) Turn the Techstream on. (d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read the DTCs. Powertrain > Engine > Trouble Codes (f) Enter the following menus: Powertrain / Engine / Data List / Vapor Pressure Pump. Powertrain > Engine > Data List

|

Tester Display | | Vapor Pressure Pump |

(g) Read the EVAP (Evaporative Emission) pressure displayed on the Techstream.

|

Display (DTC Output) | Test Result |

Suspected Trouble Area | Proceed to | |

P045011 | Less than 42.110 kPa(abs) [6.106 psi(abs)] |

- Wire harness/connector (canister pressure sensor - ECM)

- Canister pressure sensor

- Short in ECM circuit

| A | |

P045015 | Higher than 123.761 kPa(abs) [17.945 psi(abs)] |

- Wire harness/connector (canister pressure sensor - ECM)

- Canister pressure sensor

- Open in ECM circuit

| B | |

P04502F | - |

Canister pressure sensor |

C |

| B |

| GO TO STEP 5 |

| C |

| GO TO STEP 6 |

|

A |

| |

| 2. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Disconnect the ECM connector. (b) Measure the resistance according to the value(s) in the table below.

|

Tester Connection | Condition |

Specified Condition | Suspected Trouble Area |

Proceed to | |

A19-50 (PPMP) - Body ground |

Always | Below 10 Ω |

- Wire harness/connector (canister pressure sensor - ECM)

- Short in canister pressure sensor circuit

| A | |

10 kΩ or higher |

- Wire harness/connector (canister pressure sensor - ECM)

- Short in ECM circuit

| B |

| B |

| GO TO STEP 4 |

|

A |

| |

| 3. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Disconnect the canister pump module connector. (b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

|

Tester Connection | Condition |

Specified Condition | Suspected Trouble Area |

Proceed to | |

A19-50 (PPMP) - Body ground |

Always | 10 kΩ or higher |

Short in canister pressure sensor circuit |

A | | Below 10 Ω |

Short in wire harness/connector (canister pressure sensor - ECM) |

B |

| A |

| GO TO STEP 6 |

| B |

| GO TO STEP 7 |

(a) Replace the ECM.

Click here

| NEXT |

| GO TO STEP 8 |

| 5. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

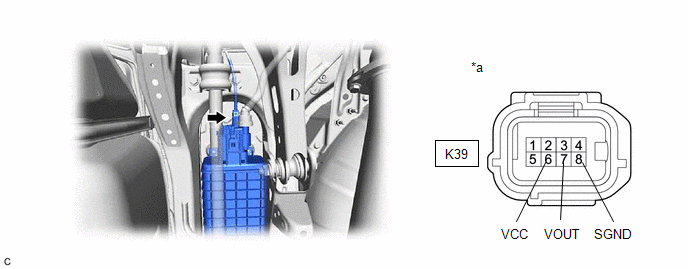

(a) Disconnect the canister pump module connector.

|

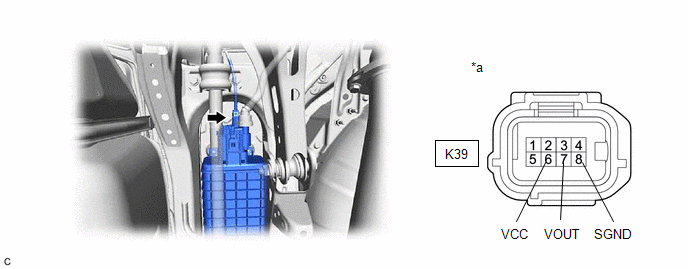

*a | Front view of wire harness connector

(to Canister Pump Module) |

- | - |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

K39-8 (SGND) - Body ground |

Always | 100 Ω or less |

(c) Turn the power switch on (IG). (d) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

K39-6 (VCC) - Body ground |

Power switch on (IG) |

4.5 to 5.5 V | |

K39-7 (VOUT) - Body ground |

Power switch on (IG) |

4.5 to 5.5 V |

| Test Result |

Suspected Trouble Area | Proceed to | |

Voltage and resistance within standard ranges |

Open in canister pressure sensor circuit |

A | | Voltage and/or resistance outside standard ranges |

Open in wire harness/connector (canister pressure sensor - ECM) |

B |

| B |

| GO TO STEP 7 |

|

A |

| |

| 6. |

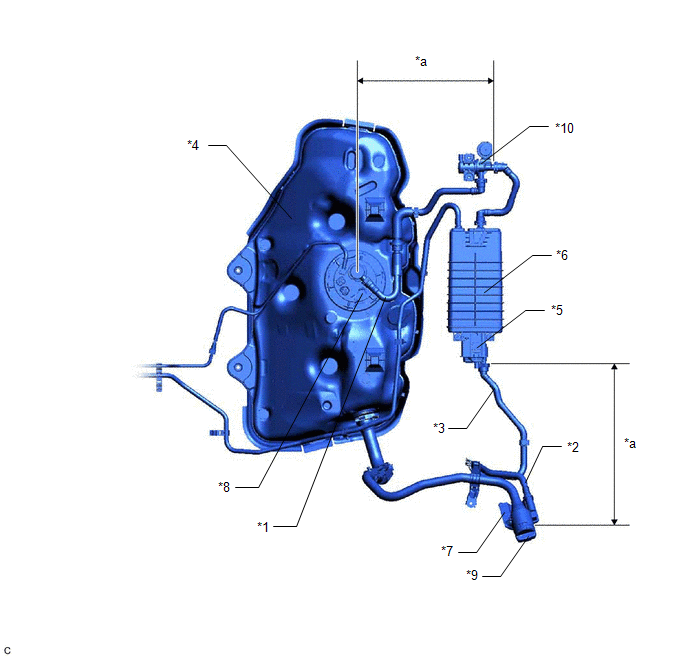

REPLACE CANISTER PUMP MODULE | (a) Replace the canister pump module.

Click here

NOTICE:

- When replacing the canister pump module, check the inside of the

canister pump module and canister, and related pipes for water, fuel and

other liquids. If liquids are present, check for disconnections and/or

cracks in the following: 1) the pipe from the air inlet port to the

canister pump module; 2) the canister filter; and 3) the fuel tank vent

hose. If liquids are present in the inside of the canister, replace the

canister and canister pump module.

- Check for filter blockage in the canister. If the charcoal filter inside

the canister is clogged, replace the canister and canister pump module.

- Check for filter blockage in the canister filter. If there is blockage in the canister filter, replace the canister filter.

|

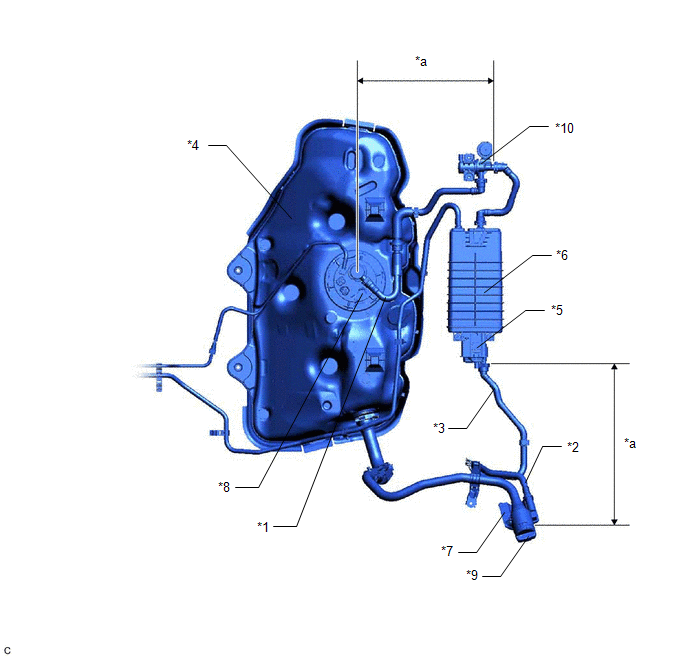

*1 | Fuel Tank Vent Hose |

*2 | Air Inlet Port | |

*3 | Vent Hose |

*4 | Fuel Tank | |

*5 | Canister Pump Module

- Canister Pressure Sensor

- Leak Detection Pump

- Vent Valve

| *6 |

Canister | | *7 |

Canister Filter | *8 |

Fuel Tank Pressure Sensor | |

*9 | Fuel Tank Cap Assembly |

*10 | Fuel Vapor-containment Valve | |

*a | Inspection Area (Check for disconnection and/or cracks) |

- | - |

| NEXT |

| GO TO STEP 8 |

| 7. |

REPAIR OR REPLACE HARNESS OR CONNECTOR (CANISTER PUMP MODULE - ECM) |

|

NEXT |

| |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG). (c) Turn the Techstream on. (d) Clear the DTCs. Powertrain > Engine > Clear DTCs

(e) Turn the power switch off and wait for at least 30 seconds.

|

NEXT |

| |

| 9. |

CHECK WHETHER DTC OUTPUT RECURS (AFTER REPAIR) |

(a) Perform the Evaporative System Check using the Techstream, referring to the Confirmation Driving Pattern.

(b) Enter the following menus: Powertrain / Engine / Utility / All Readiness. Powertrain > Engine > Utility

|

Tester Display | | All Readiness |

(c) Input the DTC: P045011, P045015 or P04502F. (d) Check the DTC judgment result. |

Techstream Display | Description | |

NORMAL |

- DTC judgment completed

- System normal

| | ABNORMAL |

- DTC judgment completed

- System abnormal

| | INCOMPLETE |

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

|

| NEXT |

| END | |