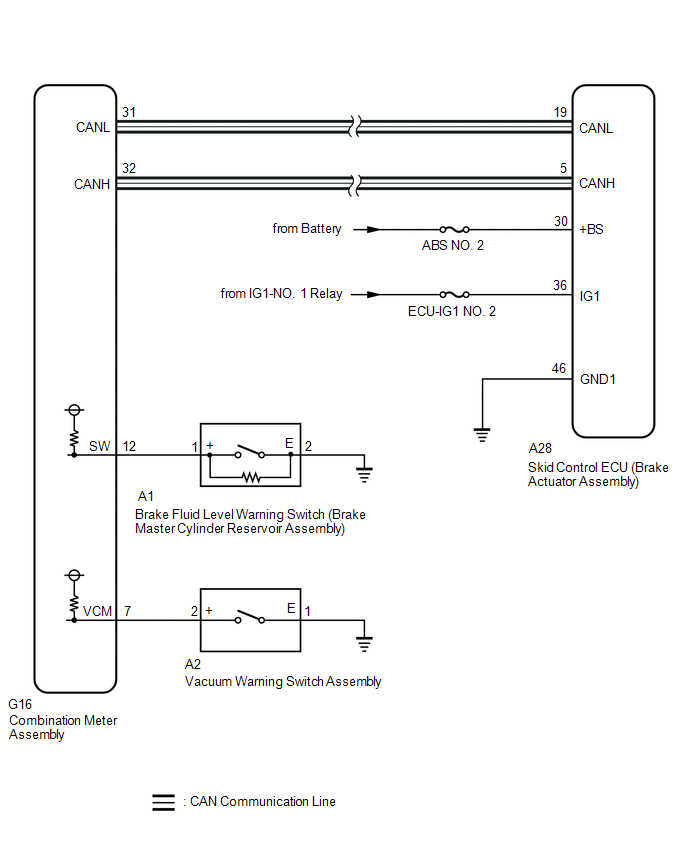

DESCRIPTION The skid control ECU (brake actuator assembly) is connected to the combination meter assembly via CAN communication. If any of the following is detected, the brake system warning light (red indicator) remains on:

WIRING DIAGRAM  CAUTION / NOTICE / HINT NOTICE:

PROCEDURE

(a) Check if CAN communication system DTCs are output. Click here

(a) Check if the skid control ECU (brake actuator assembly) connector is securely connected. OK: The connector is securely connected.

(a) Check the battery voltage. Standard Voltage:

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. (c) Disconnect the A28 skid control ECU (brake actuator assembly) connector. (d) Check both the connector case and the terminals for deformation and corrosion. OK: No deformation or corrosion. (e) Measure the voltage according to the value(s) in the table below. Standard Voltage:

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

(b) Reconnect the A28 skid control ECU (brake actuator assembly) connector. (c) Remove the reservoir filler cap and strainer. (d) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. (e) Disconnect the A1 brake fluid level warning switch (brake master cylinder reservoir assembly) connector. (f) Check both the connector case and the terminals for deformation and corrosion. OK: No deformation or corrosion. (g) Measure the resistance according to the value(s) in the table below. HINT: A float is located inside the reservoir. Its position changes according to the brake fluid level. Standard Resistance:

(h) If there is no problem after finishing the above check, adjust the brake fluid level to the MAX level.

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. (b) Disconnect the G16 combination meter assembly connector. (c) Check both the connector case and the terminals for deformation and corrosion. OK: No deformation or corrosion. (d) Measure the resistance according to the value(s) in the table below. Standard Resistance:

(a) Reconnect the A1 brake fluid level warning switch (brake master cylinder reservoir assembly) connector. (b) Reconnect the G16 combination meter assembly connector. (c) Inspect the vacuum warning switch assembly. Click here OK: The vacuum warning switch assembly is normal.

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. (b) Disconnect the A2 vacuum warning switch assembly connector. (c) Disconnect the G16 combination meter assembly connector. (d) Check both the connector case and the terminals for deformation and corrosion. OK: No deformation or corrosion. (e) Measure the resistance according to the value(s) in the table below. Standard Resistance:

(a) Reconnect the A2 vacuum warning switch assembly connector. (b) Reconnect the G16 combination meter assembly connector. (c) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Data List. Chassis > ABS/VSC/TRAC/EPB > Data List

(d) Check the Techstream display condition of the brake system warning light (red indicator).

|

Toyota Avalon (XX50) 2019-2022 Service & Repair Manual > Suspension Control Ecu: Installation

INSTALLATION PROCEDURE 1. INSTALL ABSORBER CONTROL ECU (a) Install the absorber control ECU with the 2 nuts. Torque: 7.5 N·m {76 kgf·cm, 66 in·lbf} NOTICE: Avoid any impact to the absorber control ECU. Do not drop the absorber control ECU. If it is dropped, replace it with a new one. (b) Connect ...