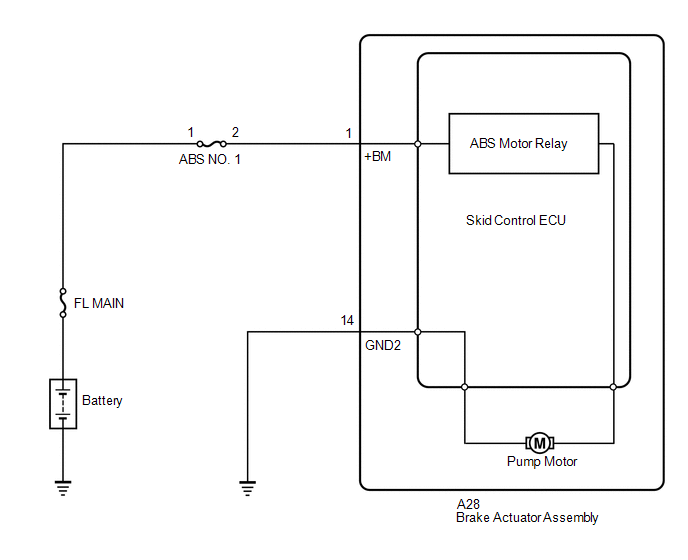

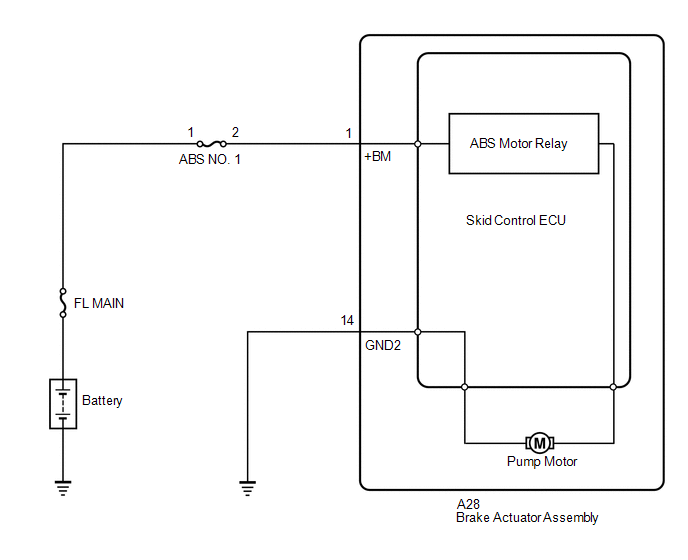

DESCRIPTION The ABS motor

relay supplies power to the pump motor. While the ABS is activated, the

skid control ECU (brake actuator assembly) turns the ABS motor relay on

to operate the pump motor. If the voltage

supplied to the ABS motor relay (+BM) is too low due to low voltage from

the battery or alternator, this DTC may be stored. |

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area | |

C146C | Open Circuit in ABS Motor Relay Circuit |

Any of the following is detected:

- When the ABS motor relay is actuated, voltage is not supplied to the pump motor.

- When the ABS motor relay is not actuated, voltage in the pump motor is high.

- The skid control ECU (brake actuator assembly) judges that pump motor operation is abnormal.

|

- ABS NO. 1 fuse

- ABS motor relay circuit

- ABS motor relay (brake actuator assembly)

| DTC Detection Conditions: C146C | |

Vehicle Condition | |

Pattern 1 | Pattern 2 |

Pattern 3 | |

Diagnosis Condition | The ABS motor relay is actuated. |

○ | - |

- | | The ABS motor relay is not actuated. |

- | ○ |

- | |

Malfunction Status | Voltage is not supplied to the pump motor. |

○ | - |

- | | Voltage in the pump motor is high. |

- | ○ |

- | | The skid control ECU (brake actuator assembly) judges that pump motor operation is abnormal. |

- | - |

○ | |

Detection Time | - |

- | - | |

Number of Trips | 1 trip |

1 trip | 1 trip |

HINT: DTC will be output when conditions for either of the patterns in the table above are met. WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the skid control ECU (brake actuator assembly), perform

system variant learning and acceleration sensor zero point calibration.

Click here

- Inspect the fuses for circuits related to this system before performing the following procedure.

HINT: When

C1241 and/or C1417 is output together with C146C, inspect and repair the

trouble areas indicated by C1241 and/or C1417 first. for C1241: Click here

for C1417: Click here

PROCEDURE

| 1. |

PERFORM ACTIVE TEST USING TECHSTREAM (ABS MOTOR RELAY) |

(a) Connect the Techstream to the DLC3. (b) Start the engine. (c) Enter the following menus: Chassis / ABS/VSC/TRAC/EPB / Active Test. Chassis > ABS/VSC/TRAC/EPB > Active Test

|

Tester Display | Measurement Item |

Control Range | Diagnostic Note | |

Motor Relay | ABS motor relay |

Relay OFF/ON | Operating sound of motor can be heard | Chassis > ABS/VSC/TRAC/EPB > Active Test

|

Tester Display | | Motor Relay |

(d) Check the operating sound of the pump motor when operating it using the Techstream.

|

Result | Proceed to | |

Operating sound is heard |

A | | Operating sound is not heard |

B |

| B |

| GO TO STEP 3 |

|

A |

| |

HINT: This DTC is stored when a problem is identified in the skid control ECU (brake actuator assembly).

The ABS motor relay is in the skid control ECU (brake actuator assembly).

Therefore,

ABS motor relay inspection and ABS motor relay unit inspection cannot

be performed. Be sure to check if the DTC is output again before

replacing the skid control ECU (brake actuator assembly). (a) Clear the DTCs. Chassis > ABS/VSC/TRAC/EPB > Clear DTCs

(b) Turn the engine switch off. (c) Start the engine. (d) Drive the vehicle at a speed of 40 km/h (25 mph) or more for 30 seconds or more.

(e) Check if the same DTC is output. Chassis > ABS/VSC/TRAC/EPB > Trouble Codes

|

Result | Proceed to | |

C146C is not output | A | |

C146C is output | B |

HINT:

- If a speed signal of 40 km/h (25 mph) or more is received by the skid

control ECU (brake actuator assembly) with the engine switch on (IG),

the skid control ECU (brake actuator assembly) performs self diagnosis

of the motor circuit.

- If the normal system code is output (no DTCs are output), slightly

jiggle the connectors, wire harness, and fuses of the skid control ECU

(brake actuator assembly).

- If any DTCs are output while jiggling a connector or wire harness of the

skid control ECU (brake actuator assembly), inspect and repair the

connector or wire harness.

- If no DTCs were output when reconfirming DTCs, checking for intermittent

problems is necessary because it is suspected that the original DTCs

were stored due to the poor connection of a connector terminal.

| A |

| USE SIMULATION METHOD TO CHECK |

| B |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

| 3. |

CHECK HARNESS AND CONNECTOR (+BM TERMINAL) |

| (a) Turn the engine switch off. |

|

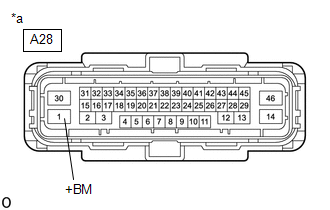

|

*a | Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly)) | | |

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK: The connector is securely connected. (c) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK: No deformation or corrosion. (e) Measure the voltage according to the value(s) in the table below.

Standard Voltage: |

Tester Connection | Condition |

Specified Condition | |

A28-1 (+BM) - Body ground |

Always | 11 to 14 V |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (+BM CIRCUIT) |

|

OK |

| |

| 4. |

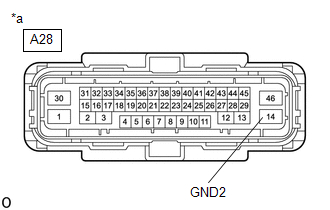

CHECK HARNESS AND CONNECTOR (GND2 TERMINAL) |

| (a) Measure the resistance according to the value(s) in the table below.

Standard Resistance: |

Tester Connection | Condition |

Specified Condition | |

A28-14 (GND2) - Body ground |

Always | Below 1 Ω | |

|

|

*a | Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly)) | | |

| OK |

| REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (GND2 CIRCUIT) | |